-

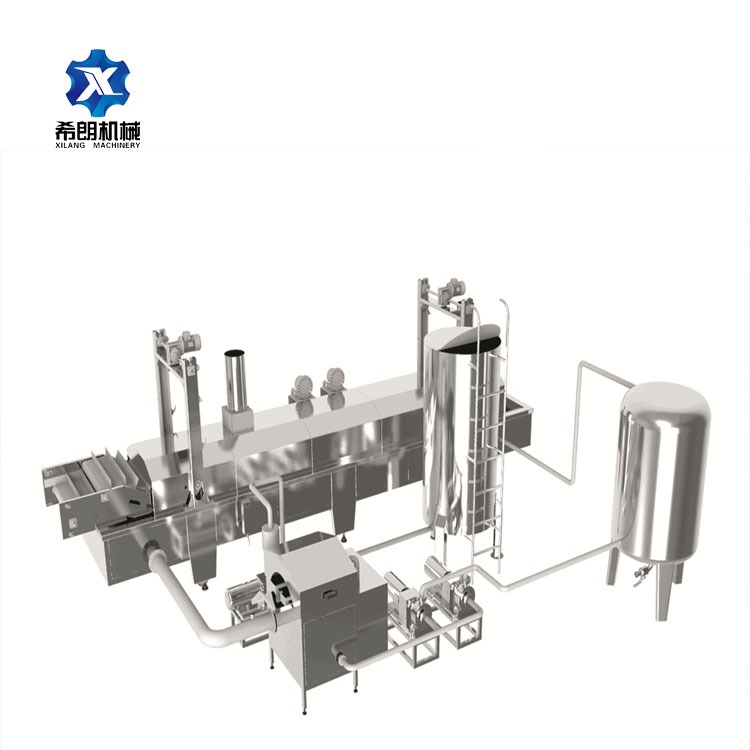

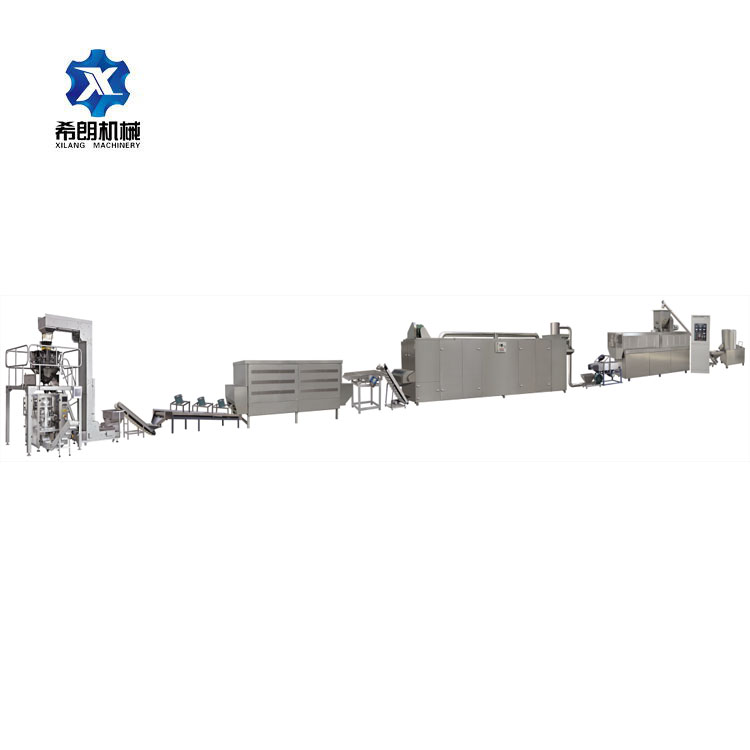

Automatic Continous Frying Equipment

1. Semi-automatic frying machine is suitable for beans, nuts, cat ears, shell cakes and other noodles and puffed food frying. 2. High and low temperature oil structure, avoid residue coking, thus prolonging the service life of oil. 3. Automatic stirring device, so that the product is heated more evenly, oil temperature can be controlled at 0-300℃. 4.Converter(used to control the speed of feeding system,cutting system and control system,can protect of the motor)use the brand of Delta,Pioneer,CHNT or Schneider.

Read More -

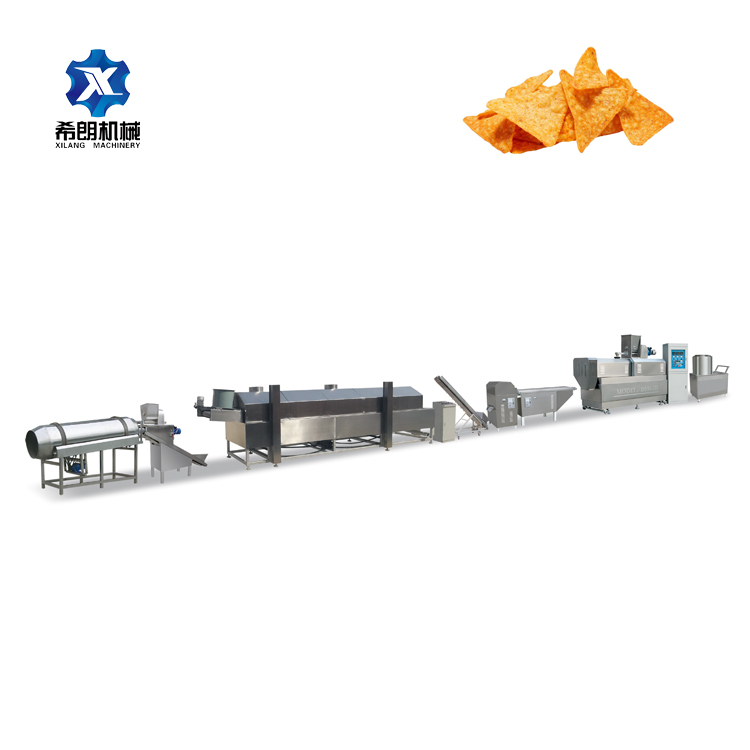

Crispy Fried Corn Bugle Chips Snacks Making Machine

1.Xilang fried snacks production line is a new technology that replaces the traditional production by twin-screw extrusion technology.The production line including mixing materials, Extruding and expanding, Forming in one, no need boiler, and the production process is simplified, efficient, environmentally friendly and low-carbon. 2.The shape can be changed by changing the mould and the forming machine and the cutting machine, such as strips, waved square sheets, diamond sheets, pillows, and triangles. The Crispy Rice, Salad Chips, and Bugles chips are all varied,and the taste is crisp and not greasy. 3 Bugle snack making machine can produce triangles, gourd shapes, small fish cakes and so on.In addition,it also could process corn by changing cutting machine.

Read More -

cartoon pasta production line

Easy-to-cook food supplement star noodles for children produced by processing machinery for children’s supplementary food star noodles are cute in shape, attracting children’s attention and driving the baby’s appetite. In addition, star noodles do not contain preservatives. The main nutrients include protein and carbohydrates, which are suitable for babies’ delicate intestines and stomachs. Good absorption, good digestion. Easy-to-cook supplementary food star noodle processing machine. The production line has reasonable design, high degree of automation and accurate control of extrusion parameters. The host is equipped with high and low pressure spirals, which increases the use of raw materials, reduces costs, and improves product quality. The equipment has multiple functions in one machine, complete products, various patterns, and can produce long and short products.

Read More -

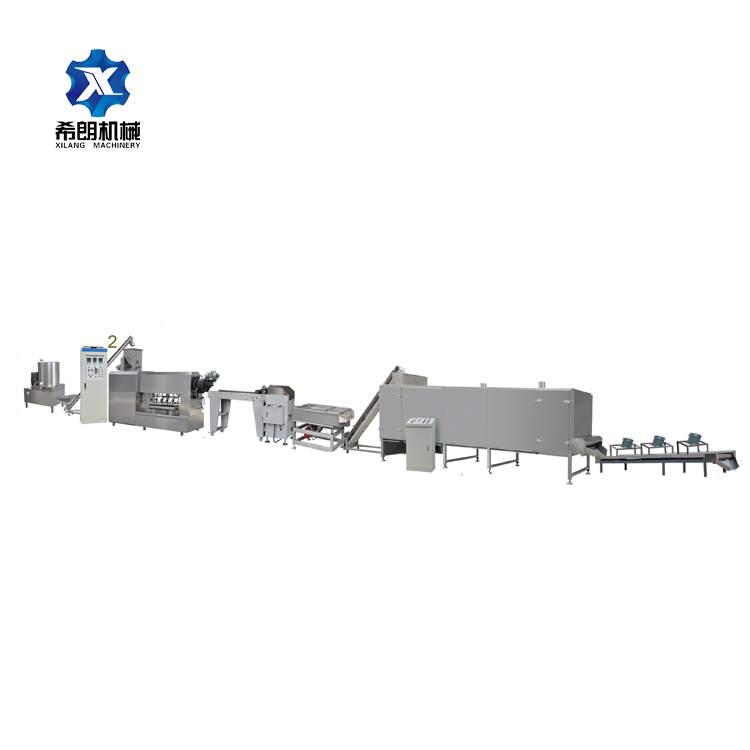

Macaroni Making Machine Production Line

1. Jinan Xilang macaroni machine equipment production line, through the replacement of different molding mold and cutting system, can produce a variety of shapes of pasta products, products natural realistic texture fine, loose taste, not cracked. 2. The production line has reasonable design, strong stability and high degree of automation. The main machine is equipped with high and low pressure screw, which increases the scope of application of raw materials, reduces the cost and improves the quality of products. 3. The host adopts advanced frequency conversion speed regulation technology, precise extrusion parameter control, stable product quality, simple operation, high efficiency and energy saving.

Read More -

infant instant porridge nutritional powder baby food processing machine line

Nutrition powder processing line 1. Technical aspects: Xilang company's expansion powder production line adopts double-screw extrusion and expansion technology to replace the traditional new technology of cooking rice noodles production. 2. Operation: The nutritional rice flour production line of Xilang Company is integrating mixing, cooking, ripening, expansion, sterilization, mixing and packaging, and there is no boiler. The production process is simplified, efficient and environmental protection 3. Application: The expansion host adopts domestic high-efficiency double screw extrusion and expansion technology, with screw segmented combination structure, which can meet the expansion processing needs of different grain raw materials. The raw materials can be a single material of rice flour and corn flour, but also its mixture 4. Product aspects: Changing raw materials and auxiliary equipment can change the product and produce different flavors of nutritional powder

Read More -

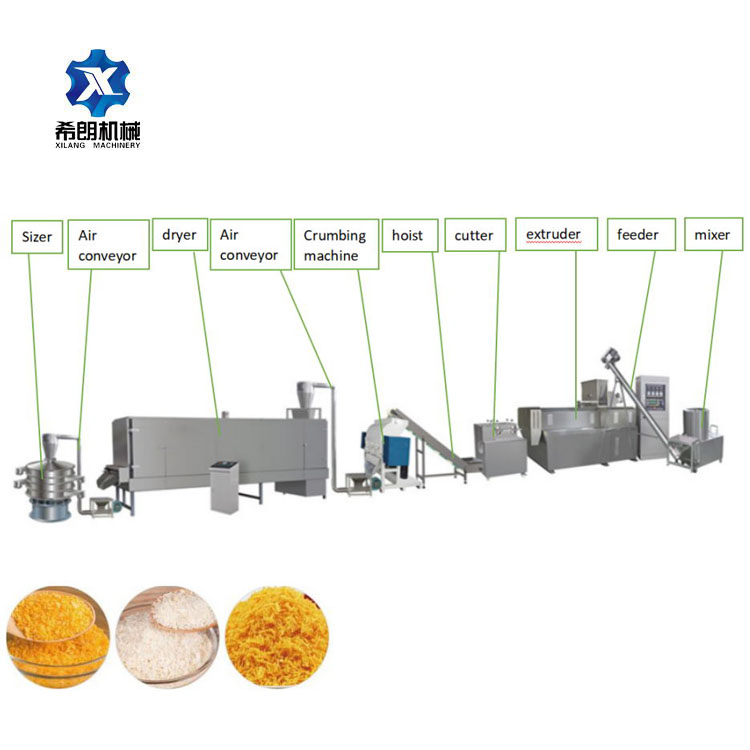

Automatic extrusion Bread Crumb flakes Making Machine

1. The production process is fully automatic line from powder material to last product forming. 2.The advantage of the line : fewer worker investment; repeated use of raw materials, no waste;high efficiency and energy saving and lower manufacturing cost. 3. The bread crumb line is multi-functional line which can produce a variety of shapes of bread crumb like bread bran, needle, granular, snowflake, flake, star shape and other shapes. 4. the basic raw materials are more extensive, corn, rice, millet, wheat, flour, starch and other grains are applicable.

Read More -

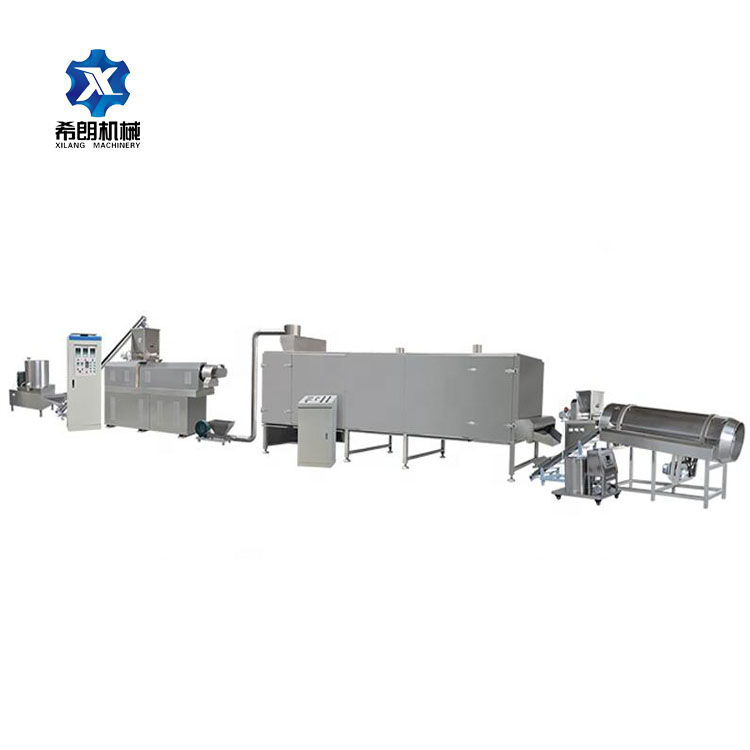

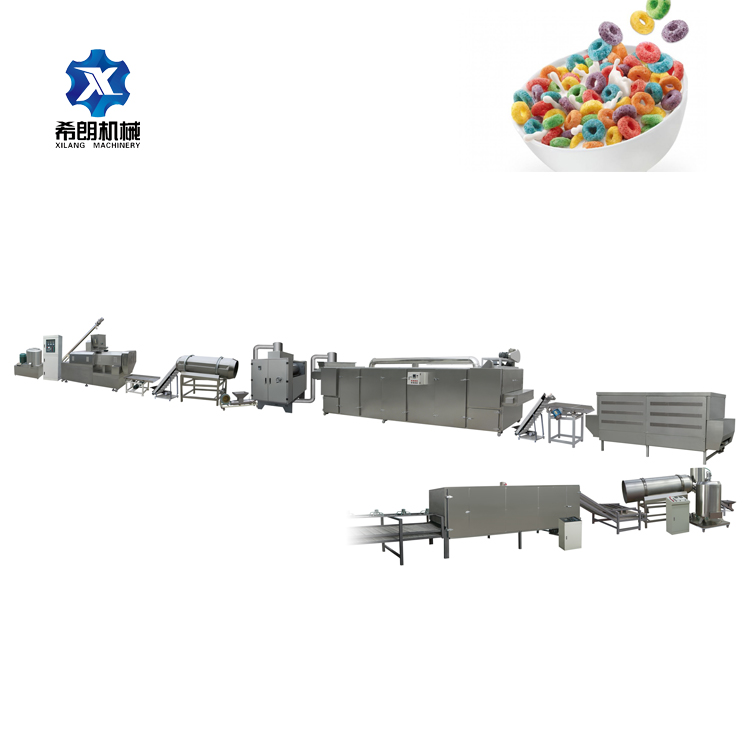

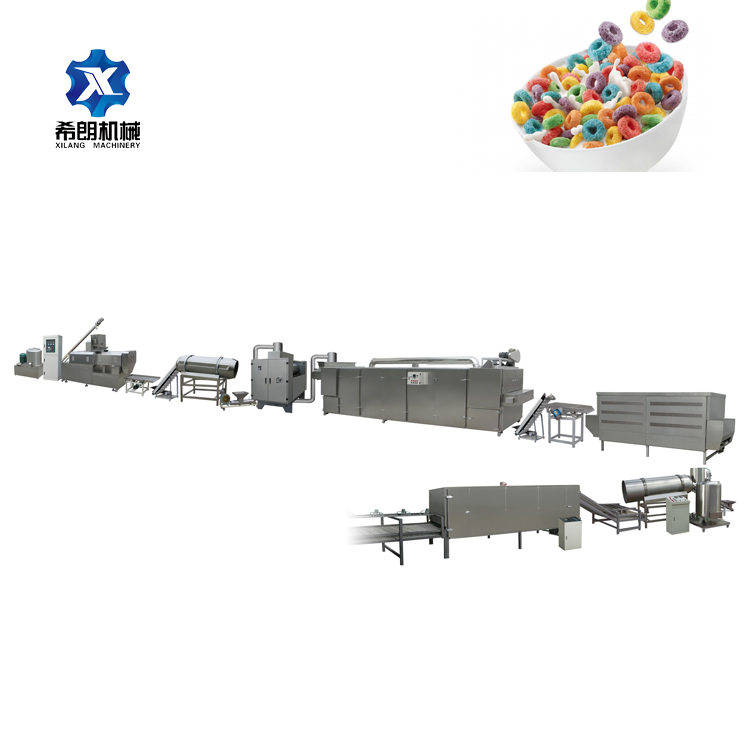

Corn Wheat Puffed Ring Snacks production line

1. The Puffed Snacks Production Line can be completed at once from ingredients, extrusion, molding, baking, spraying to finished products, with a high degree of automation.Simple operation, less occupation of labor. 2. There are many optional models, flexible equipment configuration, small investment and less land area.Special suitable for small and medium-sized enterprises. 3. various shapes and colors of puff snacks food can be produced by changing the raw material formula, seasoning formula and molding mold.

Read More -

Puffed Snow Flakes Bread Crumb Making Machine

1. The production process is fully automatic line from powder material to last product forming. 2.The advantage of the line : fewer worker investment; repeated use of raw materials, no waste;high efficiency and energy saving and lower manufacturing cost. 3. The bread crumb line is multi-functional line which can produce a variety of shapes of bread crumb like bread bran, needle, granular, snowflake, flake, star shape and other shapes. 4. the basic raw materials are more extensive, corn, rice, millet, wheat, flour, starch and other grains are applicable.

Read More -

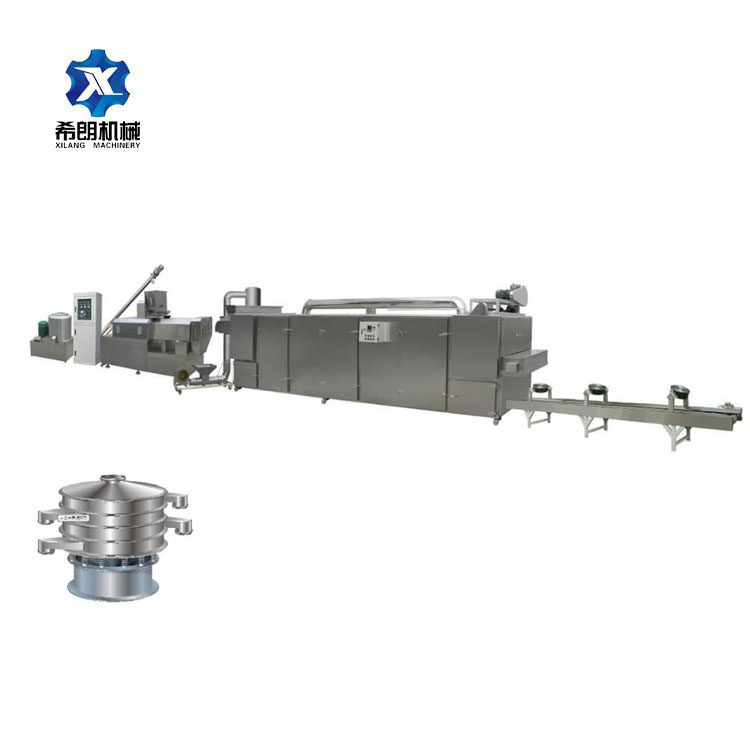

Breakfast Cereal Crispy corn flakes Extruder Machine

1. Xilong automatic breakfast corn flakes production line, the whole assembly line is reasonably matched, and can realize the whole process control, strong power operation and stable operation 2. The production line has a simple process and convenient operation.With corn, wheat, oats and other grains as raw materials, through the double screw extruder to achieve cooking, granulation, and then through pressing slices, baking, spraying and other processes, you can make raw, sweet, salty crisp ready-to-eat breakfast cornflakes food; 3. The production line adopts the advanced double-screw extrusion technology, instead of the traditional pressure roller adhesive, which can fully retain the nutrients in the grain. The production line can also produce breakfast grain food of various shapes.

Read More -

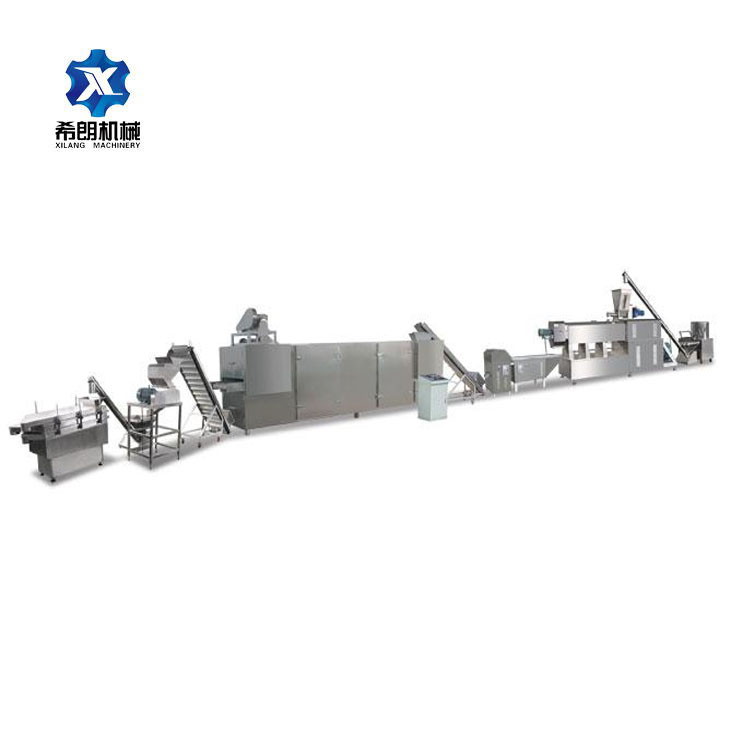

Needle shaped Bread crumb production line

1. The bread bran is a widely used food supplement, mainly used for western food fried steak, fried chicken legs and other fried ingredients. 2. Xilang automatic bread crumb production line from raw materials, puffed, hit bran, dry to the finished product assembly line operation, simple operation is less labor. 3. The surplus materials can be reused, no waste, reduces manufacturing costs and improves labor productivity.

Read More -

Self-heating Instant Artificial Rice Making Machine

1.Advanced technology: the expansion technology uses internationally advanced twin-screw extrusion technology; 2.Small equipment investment: the price is lower than the market price; 3.High output: according to different models, the output can reach up to 250kg/h; 4.Small footprint: at least 150m² can be put into production; 5.High degree of automation: fully automatic production, without manual involvement; 6.The whole machine is processed with stainless steel materials: to ensure sanitation and cleanliness.

Read More -

Granule breakfast Corn Flake production line

1) Ingredients: The ingredients of corn flakes are very important. The seasoning must ensure a good taste, especially the requirements for corn raw materials. It is directly related to whether high-quality corn flakes can be made, and the ratio of various nutrients. content. 2) Extrusion maturation molding: The extrusion maturation molding process of corn flakes is the key to producing high-quality corn flakes. The process of corn flakes must be fully matured without any puffing, only in this way can we make corn flakes that are dense, hard and crisp, with outstanding flavor.

Read More

- Home >

- Products

Get the latest price? We'll respond as soon as possible(within 12 hours)