Breakfast Cereal Crispy corn flakes Extruder Machine

Brand :XI LANG

Product origin :Jinan,China

Delivery time :2odays

Supply capacity : 100 sets per month

1. Xilong automatic breakfast corn flakes production line, the whole assembly line is reasonably matched, and can realize the whole process control, strong power operation and stable operation

2. The production line has a simple process and convenient operation.With corn, wheat, oats and other grains as raw materials, through the double screw extruder to achieve cooking, granulation, and then through pressing slices, baking, spraying and other processes, you can make raw, sweet, salty crisp ready-to-eat breakfast cornflakes food;

3. The production line adopts the advanced double-screw extrusion technology, instead of the traditional pressure roller adhesive, which can fully retain the nutrients in the grain. The production line can also produce breakfast grain food of various shapes.

1.Introduction of breakfast Cereal crisps Extruder Machine

Corn flakes are the most common cereal snack food in the world. The raw material used to process corn flakes is best to use hard dent corn, because of its high horny endosperm content, high transparency after starch gelatinization, and good product appearance. When eating, prepare corn flakes granules with boiling water. If corn flakes are put into the prepared soup, it can be made into corn flake soup.

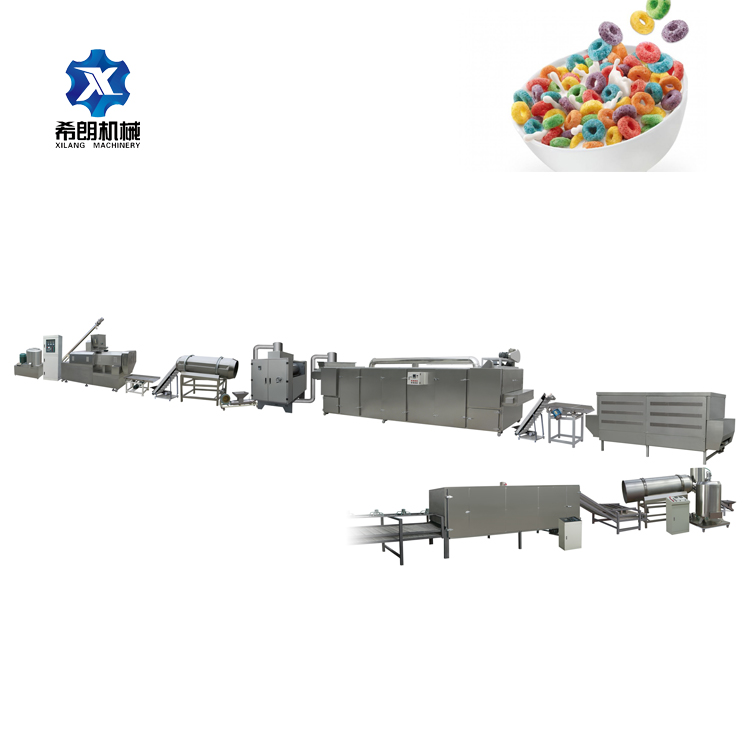

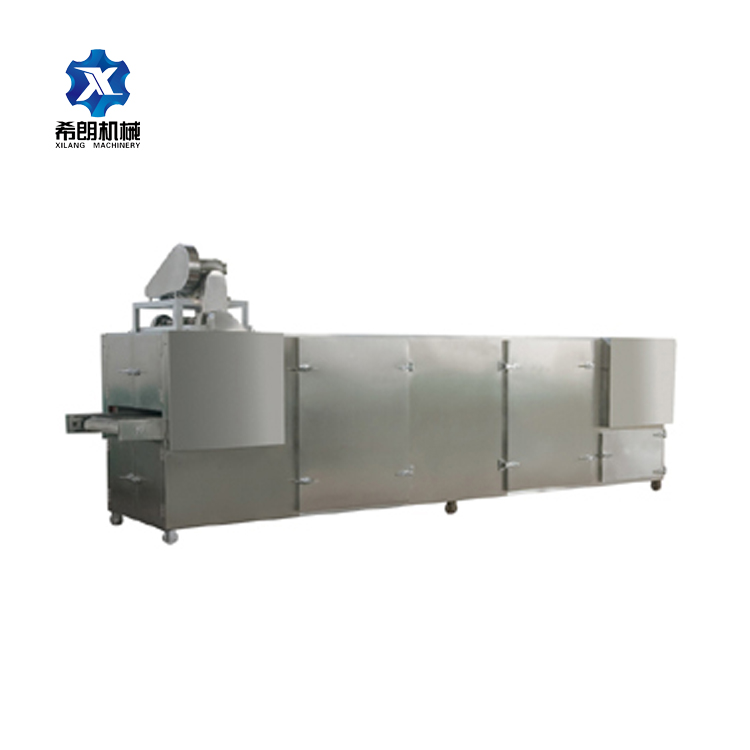

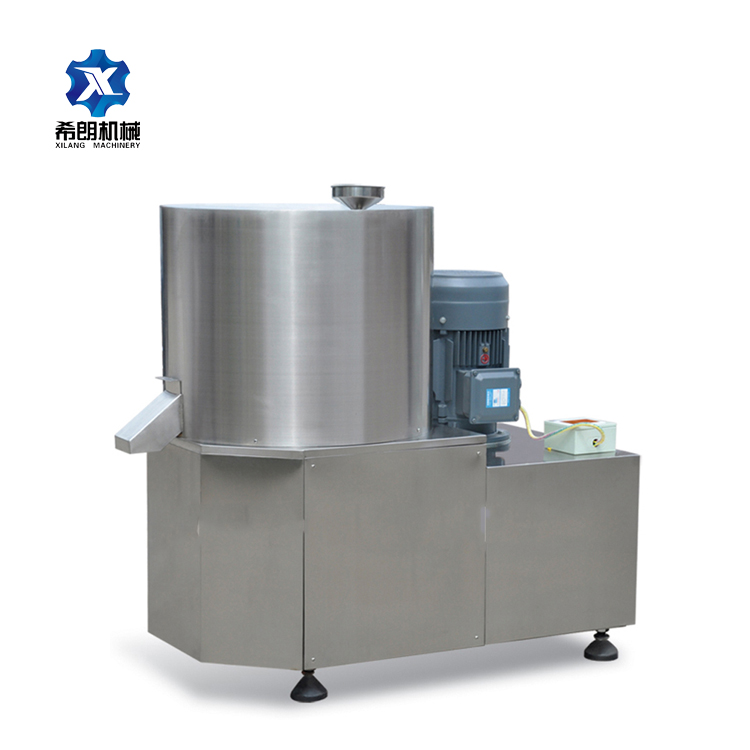

Breakfast Cereal crisps Extruder Machine use corn flour and other grain flours as their raw materials to produce various type of breakfast cereals and corn flakes. The whole produce line is made up of mixing,extrudering, flaking, drying, high temperature baking ,flavoring and cooling. Just by changing the dies or choosing suitable production process, different shapes breakfast cereals can be produced. The breakfast corn flakes production line is highly automatic and high efficiency. All the machines choose the famous band motors and best accessories for installation.

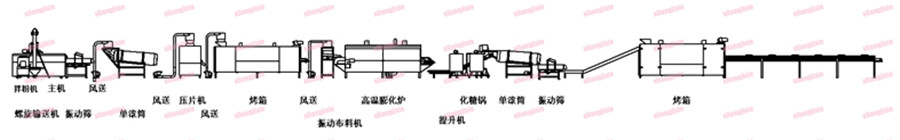

2. The Corn flakes production process line :

Mixer - screw conveyor- Twin-screw extruder -Sifter-Air conveyor -Flaking machine -Air conveyor - Three-layer oven - Hoister -Microwave Oven -Melting sugar machine -Sprayer sugar-Hoister -Roller - Hoister - Five-layer oven- Cooing machine

3.Corn flakes material and capacity produced by breakfast Cereal crisps Extruder Machine :

3.2.Output capacity of breakfast corn flakes production line: 150kg/h for corn flakes, 300 kg/h for corn flakes; 500kg/h for corn flakes,150kg/h, 250kg/h, 450kg/h for corn puffs snacks food,cereals. 160kg/h, 250kg/h for core filling snacks food.

4.Company Information:

Jinan Xilang Machine Co.,ltd is a professional Manufacturer specializing in producing Extrusion machinery,Industrial microwave drying and sterilizing equipment and related ancillary equipment.The Company is located i Jinan,the spring city of Shandong. With the strong design strength,advanced producing technology and rich manufacturing experience,the company`s products get good comments from domestic and abroad customers.

The main products of the company include machinery and equipment for pasta system, corn flakes/breakfast cereal system, soy nuggets system, pet food / fish feed system, various type drying oven system, industrial microwave oven system and so on.

Our machines have been exported to many countries of Asia, America, Africa, Europe etc. So don`t hesitate to contact with us. Xilang term from pre-sale service to after-sale service will show your choice is worth.