-

Automatic Stainless Steel Powder Grinding Machine

1. The unit is integrated with main engine, auxiliary engine, pipeline and electric control device. Stable technical performance, continuous production process, high efficiency and energy saving.Less footprint and noise. 2. The main machine is equipped with air sorting centrifugal grading shear device, no screen and no net, the uniform particle size can be adjusted. Especially suitable for crushing food materials, chemical materials, fiber materials, Chinese medicine materials, etc. 3. The cyclone dust collector and filter bag dust collector in the auxiliary machine are integrated (or separated in series) to ensure dust removal efficiency.

Read More -

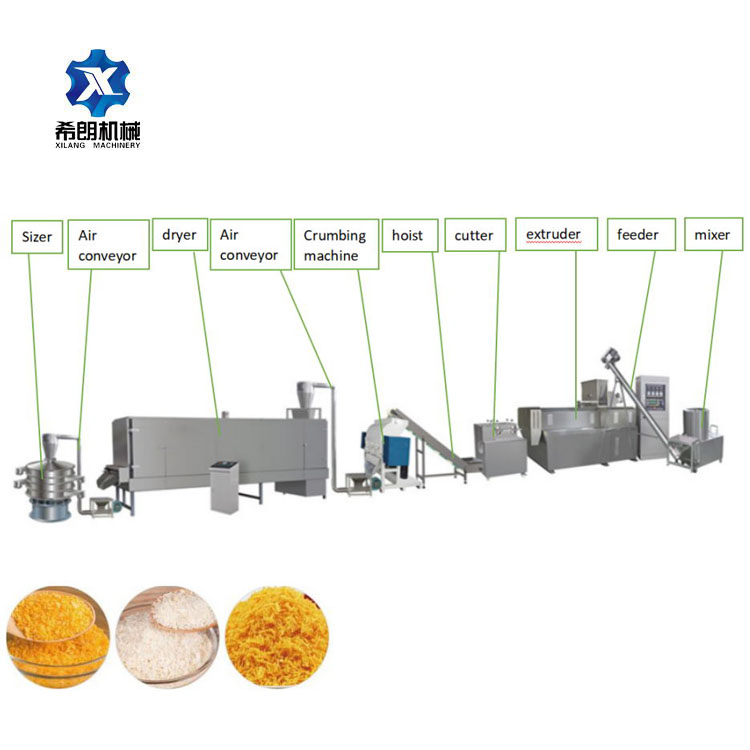

Automatic panko bread crumb making machine

1. The production process is fully automatic line from powder material to last product forming. 2.The advantage of the line : fewer worker investment; repeated use of raw materials, no waste;high efficiency and energy saving and lower manufacturing cost. 3. The bread crumb line is multi-functional line which can produce a variety of shapes of bread crumb like bread bran, needle, granular, snowflake, flake, star shape and other shapes. 4. the basic raw materials are more extensive, corn, rice, millet, wheat, flour, starch and other grains are applicable.

Read More -

Industrial biscuit making machine cookies biscuit cracker production line

1. Technology: The whole line of cookie production line adopts CPU module control, backhanging motor drive, compact structure, high degree of automation, from feeding, three pressure surface, forming, sugar screening, transportation, waste material, recycling. Baking, oil spraying, cooling and other mechanical and electrical integration automatically completed 2. Products: The company provides thousands of molds and dozens of technological formulations. Customers can produce a variety of cookie products by adjusting the molds and formulations. Such as cookies, soda crackers, crackers, cartoon crackers and so on. 3. Service: Xilang automatic biscuit production line, equipment configuration can be customized according to demand. Just determine your own plant size, pre-output products and output, we can provide you with the best solution.

Read More -

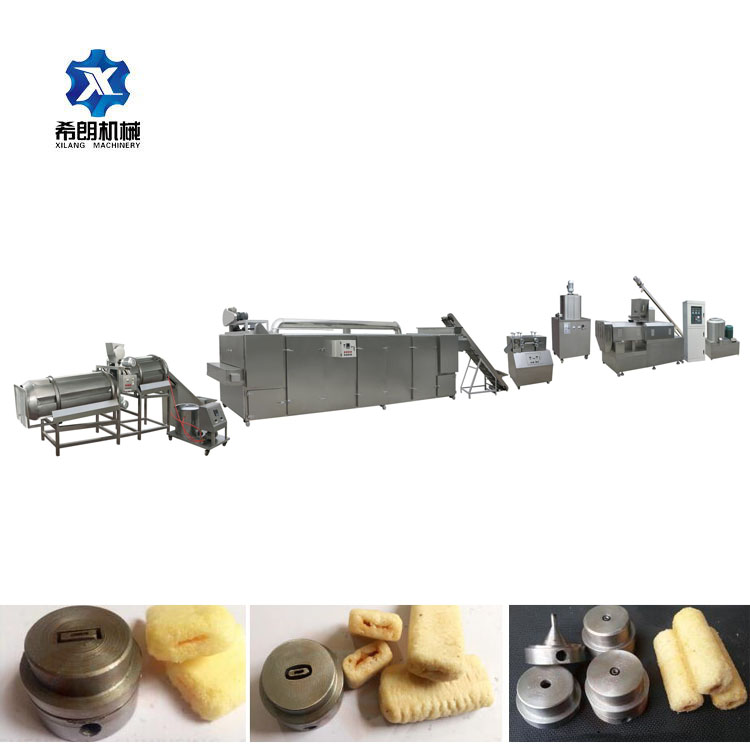

Chocolate cream filling corn snacks pillow production line

1. Core Filling Corn Snacks Food Machinery uses advanced extrusion technology and achieve atomation from mixing ,extruion ,shaping,filling,drying,flavoring,cooling. 2.Core Filling Corn Snacks Food Machinery can produce different shapes core-filling snack and puffed food by Chaning the molds. 3.The whole line have function of full automatic and easy operation. 4.After-sales Service Provided: Free spare parts, Field installation,Commissioning and training, Field maintenance and repair service, Video technical support, Online support.

Read More -

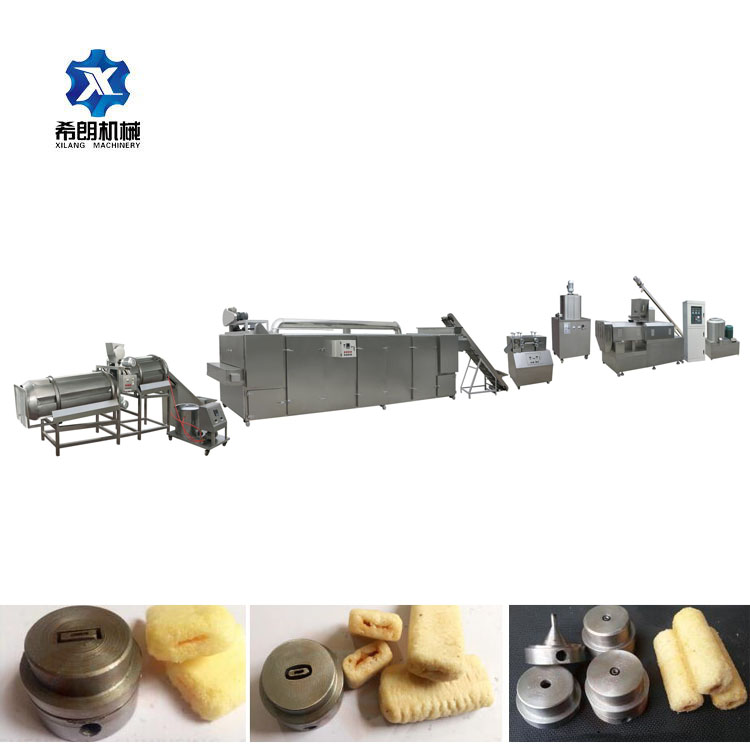

Jam center corn snacks pillow production line

1. Core Filling Corn Snacks Food Machinery uses advanced extrusion technology and achieve atomation from mixing ,extruion ,shaping,filling,drying,flavoring,cooling. 2.Core Filling Corn Snacks Food Machinery can produce different shapes core-filling snack and puffed food by Chaning the molds. 3.The whole line have function of full automatic and easy operation. 4.After-sales Service Provided: Free spare parts, Field installation,Commissioning and training, Field maintenance and repair service, Video technical support, Online support.

Read More -

Pillow Core filling corn snacks food Machinery

1. Core Filling Corn Snacks Food Machinery uses advanced extrusion technology and achieve atomation from mixing ,extruion ,shaping,filling,drying,flavoring,cooling. 2.Core Filling Corn Snacks Food Machinery can produce different shapes core-filling snack and puffed food by Chaning the molds. 3.The whole line have function of full automatic and easy operation. 4.After-sales Service Provided: Free spare parts, Field installation,Commissioning and training, Field maintenance and repair service, Video technical support, Online support.

Read More -

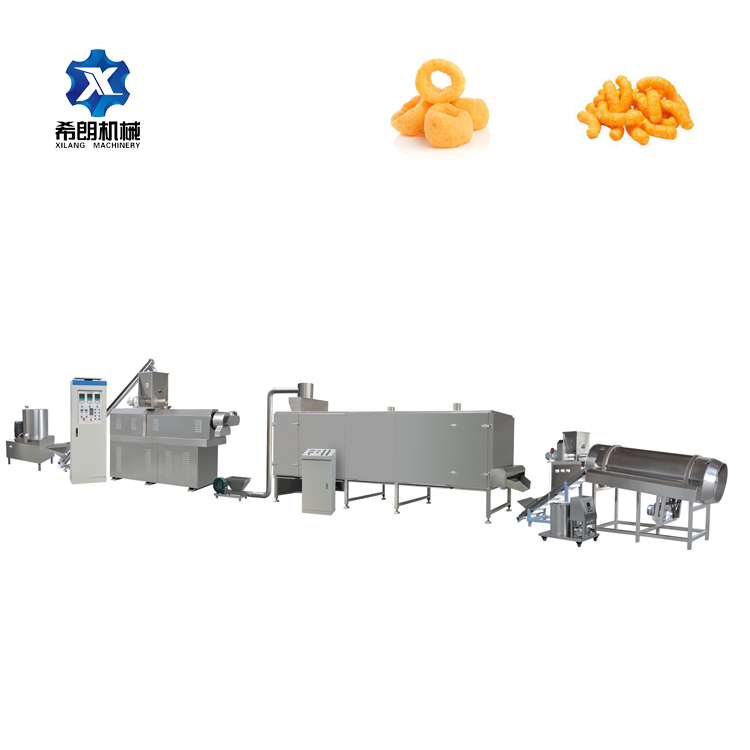

Automatic Puffed Snack Food Processing Line

1. puffed snack food production line have function of High automatic degree , all machines just need 2 workers for operation. 2.Fully automatic, From mixing to flavoring The whole processing line is completed at one time. 3.corn snack extruder machine adopt twin-screw extrusion technology and are highly flexible. They can be easily modified toprocess new products 4.After-sales Service Provided: Free spare parts, Field installation,Commissioning and training, Field maintenance and repair service, Video technical support, Online support.

Read More -

Corn Puffs Snack Food Extruder Machine

1.Adopting advance twin screw extrusion technology. 2.Converter( used to control the speed of the main motor , feeding system and cutting system ) brand can be Delta,Pioneer,CHNT or Schneider. All the electric device brand can be customized as you need. 3.Provide Free spare parts After-sales , Field installation,Commissioning and training, Field maintenance and repair service, Video technical support, Online support. 4.Machine material generally is Food grade stainless steel, also can customized as require. 5.Guarantee Time is 2 year.

Read More -

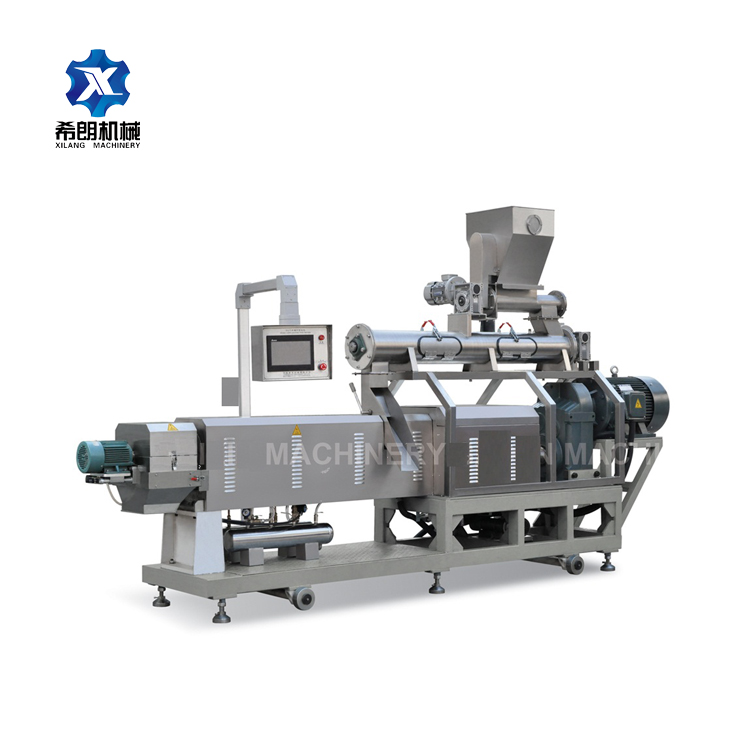

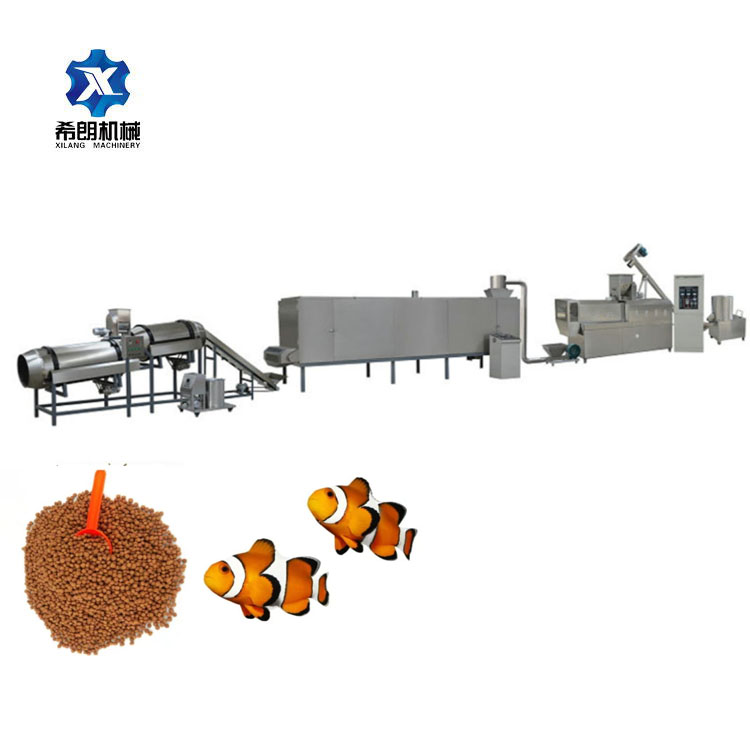

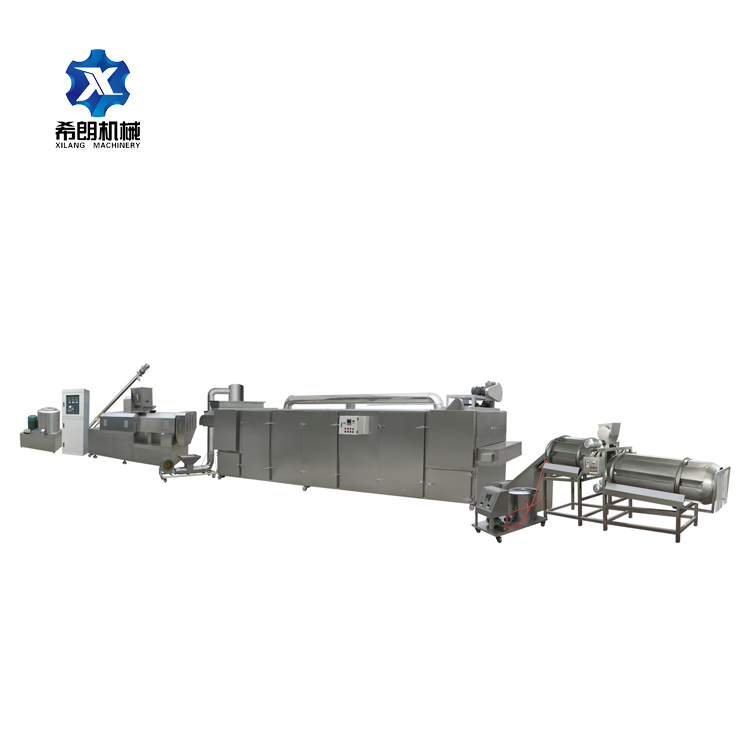

Floating fish feed pellet extruder making machine

1.Can produce floating feed, slow sinking feed, sinking feed.Small investment, high output, small area space. 2.The whole machine of small and medium-sized fish feed production line is made of stainless steel. It Can be widely used in the production of fish, shrimp, crab, abalone, sea cucumber and various ornamental fish feed. 3.The production line adopts internationally advanced twin-screw extrusion technology. can accurately control the increase of the density of the product.The puffing machine can choose dry puffing and wet puffing.

Read More -

Dry Pet Cat Dog Food Pellet Making Machine

1) All Pet food equipments are made of stainless steel. 2). The Pet food production line fully continuous and automatic. 3). provide basic Pet food formula according to your require. 4). The final Pet food shapes and sizes can be various by changing the mould.

Read More -

Puffed Corn Snack Food Extruder Machine

1.Xilang puffed snack food production line, from raw material preparation, extrusion, molding, cutting, baking, spraying, seasoning to finished products, high degree of automation. 2. The production line is characterized by multiple models, flexible configuration, wide range of raw materials, various products and simple operation. With appropriate configuration, it can produce Taiwan crispy rice cake, sandwich tube, sandwich rice cake, wheat sauce, McChicken flavor block, nutritious breakfast, corn chip and other products. 3. Puffed food has a crisp taste, easy to digest, unique aroma and easy to carry. It is the ideal leisure food for consumers.

Read More -

Industrial Continuous Microwave Dryer stainless steel Fully automatic operation widely using

Industrial microwave equipment adopt food grade stainless steel materials. Microwave generator design by ourselves,with long life . Microwave drying machine is PLC control and touch screen ,it is easy operation.

Read More

- Home >

- Products

Get the latest price? We'll respond as soon as possible(within 12 hours)