-

Automatic operation Fried Bugles Corn Chips Snacks Food Making Equipment

1 bugles snack making machines are made by stainless steel, this line is with reasonable design and with high automation; 2 the screws of puff frying snack production line are made by alloy steel, with building block system structure and self-cleaning function 3 Raw material of bugles snack making machine: Wheat flour, potato starch, potato flour, corn starch, cassava starch and so on. 4.After-sales Service Provided: Free spare parts, Field installation,Commissioning and training, Field maintenance and repair service, Video technical support, Online support.

Read More -

cookies biscuit cracker production line

1. Technology: The whole line of cookie production line adopts CPU module control, backhanging motor drive, compact structure, high degree of automation, from feeding, three pressure surface, forming, sugar screening, transportation, waste material, recycling. Baking, oil spraying, cooling and other mechanical and electrical integration automatically completed 2. Products: The company provides thousands of molds and dozens of technological formulations. Customers can produce a variety of cookie products by adjusting the molds and formulations. Such as cookies, soda crackers, crackers, cartoon crackers and so on. 3. Service: Xilang automatic biscuit production line, equipment configuration can be customized according to demand. Just determine your own plant size, pre-output products and output, we can provide you with the best solution.

Read More -

Industrial Continuous Microwave Tunnel Conveyor Machine with PLC automatically system control

Industrial microwave equipment adopt food grade stainless steel materials. Microwave generator design by ourselves,with long life . Microwave drying machine is PLC control and touch screen ,it is easy operation.

Read More -

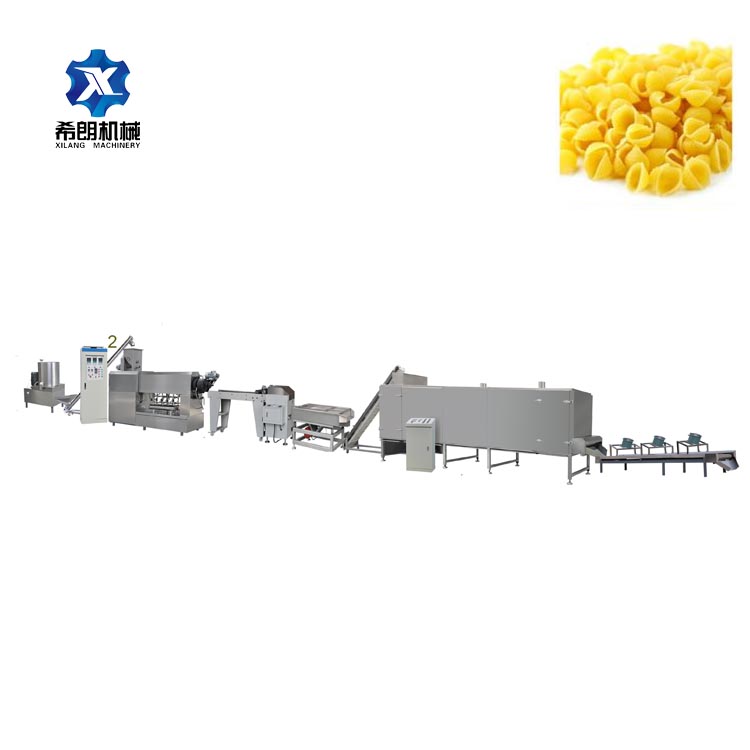

300 kg per hour CE Screw Pasta Macaroni Manufacturing Line

1. The whole macaroni manufacturing line 300 kg per hour is made up Mixing system, extruding system,drying system. 2.macaroni manufacturing line 300 kg per hour adopt most advanced extrsuion technology to produce various shapes macaroni. 3.macaroni manufacturing line 300 kg per hour to use 100% flour as raw material, you also could use the corn flour . 4.macaroni manufacturing line 300 kg per hour wide range of model for choosing,we could design according to your detail request.

Read More -

Small Corn Wheat pasta macaroni manufacturing machine

1.macaroni manufacturing machine adopt most advanced extrsuion technology to produce various shapes macaroni. 2.pasta maker machine macaroni line to use 100% flour as raw material, you also could use the corn flour . 3. The mold of pasta maker machine macaroni adopt advance intaly technology. 4.Wide range of model for choosing,we could design according to your detail request.

Read More -

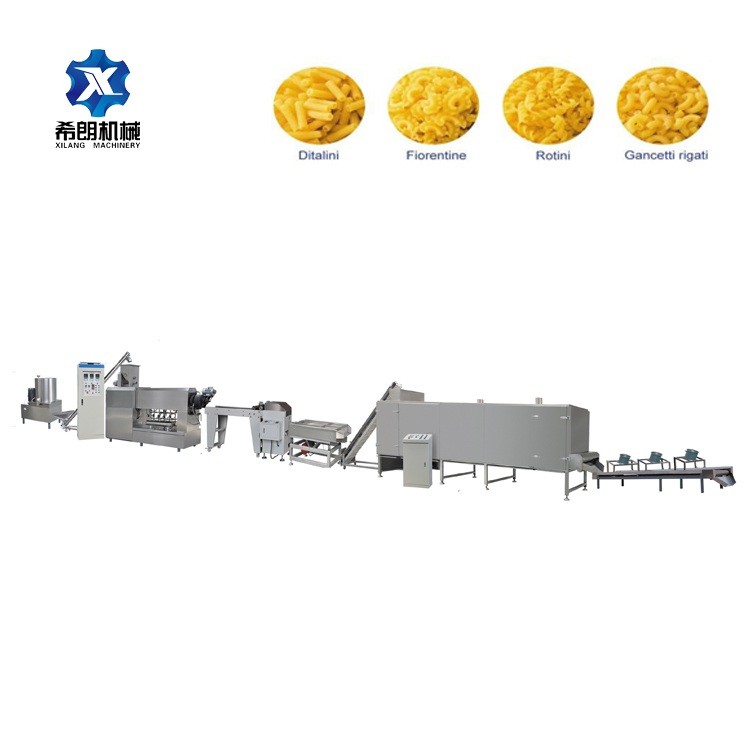

Automatic Italy Macaroni Pasta Production line

1. The whole italy macaroni production line is made up Mixing system, extruding system,drying system. 2.italy macaroni production line adopt most advanced extrsuion technology to produce various shapes macaroni. 3.pasta maker machine macaroni line to use 100% flour as raw material, you also could use the corn flour . 4.Wide range of model for choosing,we could design according to your detail request.

Read More -

Industrial Dehydrator Fruit Food Cocoa Black Pepper Hot Air Circulation Tunnel Drying Machine Continuous Belt Dryer

Industrial microwave equipment adopt food grade stainless steel materials. Microwave generator design by ourselves,with long life . Microwave drying machine is PLC control and touch screen ,it is easy operation.

Read More -

Eco Small biscuit making machine cookies biscuit cracker production line

1. Technology: The whole line of cookie production line adopts CPU module control, backhanging motor drive, compact structure, high degree of automation, from feeding, three pressure surface, forming, sugar screening, transportation, waste material, recycling. Baking, oil spraying, cooling and other mechanical and electrical integration automatically completed 2. Products: The company provides thousands of molds and dozens of technological formulations. Customers can produce a variety of cookie products by adjusting the molds and formulations. Such as cookies, soda crackers, crackers, cartoon crackers and so on. 3. Service: Xilang automatic biscuit production line, equipment configuration can be customized according to demand. Just determine your own plant size, pre-output products and output, we can provide you with the best solution.

Read More -

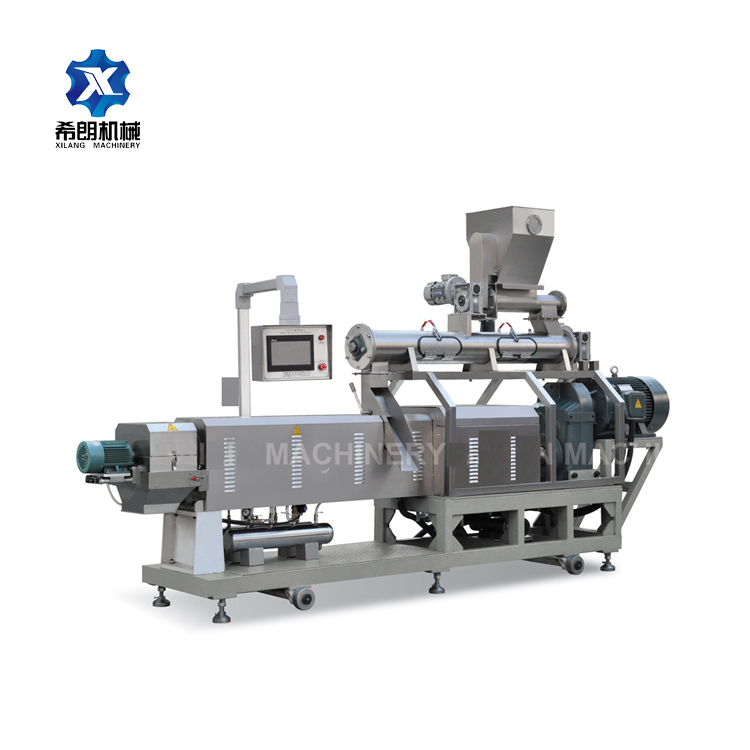

Industrial 100-400 kg/h macaroni pasta making machine

1.Macaroni making machine adopt most advanced technology. 2.Pasta macaroni machine line to use 100% flour as raw material.also can use the corn flour . 3. The mold of pasta extruder is advance intaly technology 4.Small to big capacity to meet your different market.

Read More -

Breakfast Cereal Corn Flakes Production Manufacturing Equipments

Breakfast cereal food is one popular breafast cereal food which is processed by this line using grain corn as basic material,the following are main introduction which help you know this kind of machine well. 1)corn flakes manufacturing plant Ingredients: corn flakes manufacturing plantingredients of corn flakes are very important. The seasoning must ensure a good taste, especially the requirements for corn raw materials. It is directly related to whether high-quality corn flakes can be made, and the ratio of various nutrients. content. 2) corn flakes manufacturing plant Extrusion maturation molding: The extrusion maturation molding process of corn flakes is the key to producing high-quality corn flakes. The process of corn flakes must be fully matured without any puffing, only in this way can we make corn flakes that are dense, hard and crisp, with outstanding flavor.

Read More -

Multifunction Twin Screw Extruder Machine

1.The screws of extruder material is 38CrMnAl, which is wear-resisting. 2.The processing line has self-cleaning function. 3.The main body material is stainless steel, which is easy to be cleaned. 4.Guarantee time is 2 year. 5.Converter(used to control the speed of feeding system,cutting system and control system,can protect of the motor)use the brand of Delta,Pioneer,CHNT or Schneider. 6.After-sales Service Provided: Free spare parts, Field installation,Commissioning and training, Field maintenance and repair service, Video technical support, Online support.

Read More -

double extruded breakfast baby infant grain instant cereal nutritional powder food making machine

Nutrition powder processing line 1. Technical aspects: Xilang company's expansion powder production line adopts double-screw extrusion and expansion technology to replace the traditional new technology of cooking rice noodles production. 2. Operation: The nutritional rice flour production line of Xilang Company is integrating mixing, cooking, ripening, expansion, sterilization, mixing and packaging, and there is no boiler. The production process is simplified, efficient and environmental protection 3. Application: The expansion host adopts domestic high-efficiency double screw extrusion and expansion technology, with screw segmented combination structure, which can meet the expansion processing needs of different grain raw materials. The raw materials can be a single material of rice flour and corn flour, but also its mixture 4. Product aspects: Changing raw materials and auxiliary equipment can change the product and produce different flavors of nutritional powder

Read More

- Home >

- Products

Get the latest price? We'll respond as soon as possible(within 12 hours)