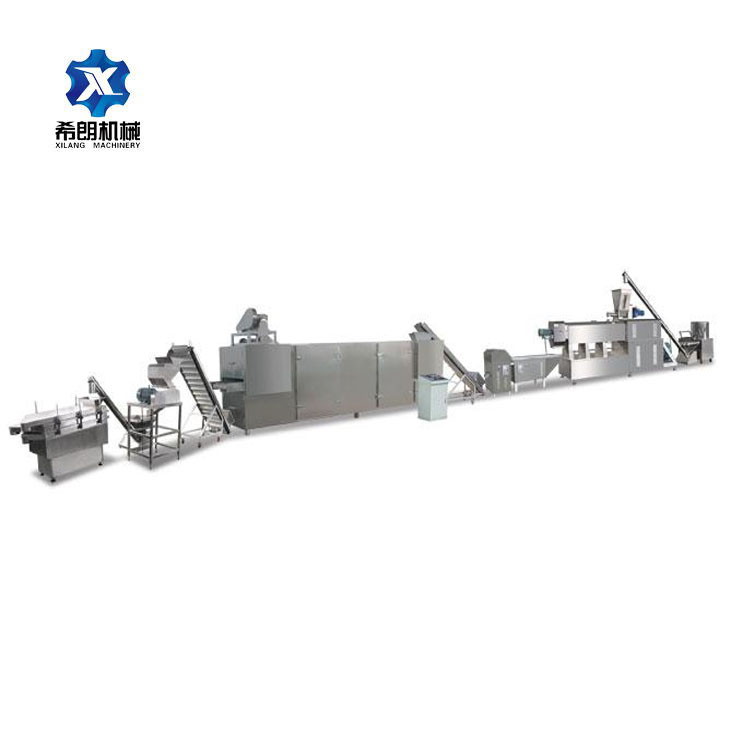

Needle shaped Bread crumb production line

Brand :XI LANG

Product origin :Jinan,China

Delivery time :20days

Supply capacity : 100 sets per month

1. The bread bran is a widely used food supplement, mainly used for western food fried steak, fried chicken legs and other fried ingredients.

2. Xilang automatic bread crumb production line from raw materials, puffed, hit bran, dry to the finished product assembly line operation, simple operation is less labor.

3. The surplus materials can be reused, no waste, reduces manufacturing costs and improves labor productivity.

1.Product Description of Needle shaped Bread crumb production line

Breif Introduction of Xilang needle shaped bread crumb production line:

"Bread crumb" is a widely used food additives, used for fried onion rings, western steak, fried chicken legs, etc. The production line takes flour and starch as raw materials, extrudes expanded billet by twin screw extruder, which can be used to screen needle bran and snowflake bran. It can also be extruded and rotated to produce flake and spherical bran, with high production efficiency and no waste.

raw material:

corn, rice, millet, wheat, flour, starch and other grains are applicable.

Product:

this processing line can make various shapes and sizes bread crumb ,such as Japanese long needle shape,US granular shape, Snowflake shape and so on..

2.The technical specification of needle-shaped production line:

Model | XL65 bread crumb production line | XL70 bread crumb production line | XL85 bread crumb production line |

Installed power | 80kw | 100kw | 140kw |

Actual consumption power | 60kw | 80kw | 110kw |

Production capacity | 100-150kg/h | 150-220kg/h | 300-400kg/h |

Appearance size(mm) | 1800x1200x2200 | 1900x1500x2200 | 2400x1500x2300 |

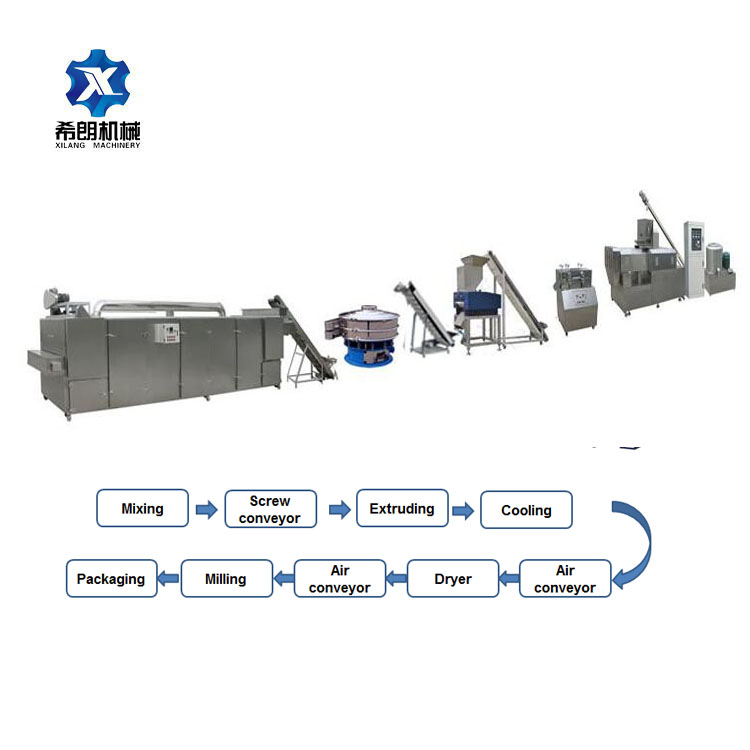

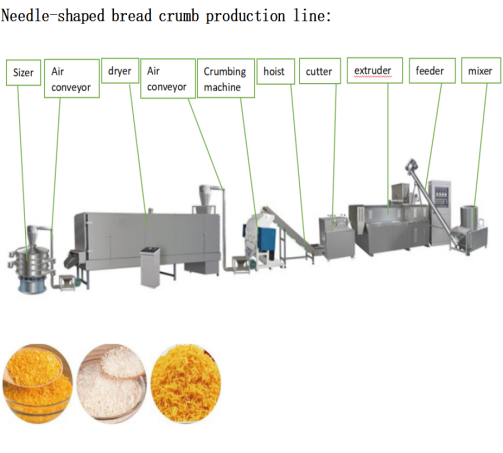

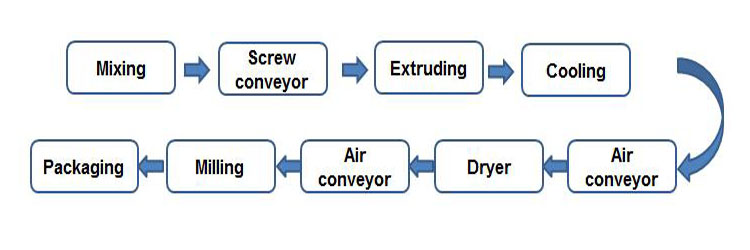

3. Flow Chart of Panko Bread Crumb Extruder Process flow:

Mixing system -- Extruding system -- Pulling and cutting system -- Crushing system -- Drying system --- Selecting system -- packaging system

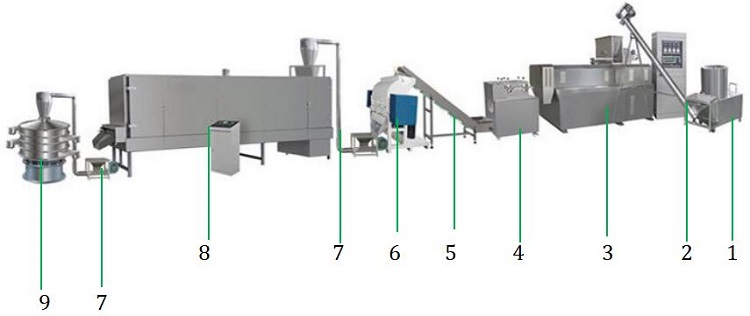

Equipment Configuration:

mixer- screw feeder - twin screw extruder - multi-function cutting machine - large hoist - crumbing machine - Z conveyor - sieve machine - muti-layer oven

No. | Description | Quantity | Function |

1 | mixer | 1pc | Mix the materials with water or other liquid. |

2 | Screw Conveyor | 1pc | Convey the materials into twin screw extruder. |

3 | Twin Screw Extruder | 1pc | Raw material is curing and puffed in extruder, becoming different shapes by changing moulds. |

4 | Cutter | 1pc | Cut long products to short |

5 | Hoist | 1pc | Convey the products into crumbing machine |

6 | Crusher machine | 1pc | Crush the products to needle-like shapes |

7 | Air Conveyor | 2pc | Convey the products relying on the wind-force |

8 | Multi-layer oven | 1pc | bake and dry the products |

9 | Vibrating Sizer | 1pc | Vibrating and size the materials with different diameters. |

4.Sample Photos

5.Main machine features: twin screw extruder

1. Centralized control of touch screen, accurate and convenient

2. The motor and the distribution box are directly connected for transmission, with less energy loss

3. Imported bearing set is adopted, with strong carrying capacity

4. The barrel is equipped with a water injection device to better adapt to raw material and quality requirements

5. High-speed tool steel screw, hardness 262, long service life

6. Building block type combined screw can be combined freely according to different raw materials and products

7. Linear bearing adjustment is safe, accurate and fast

6.Packaging, transportation

7.Company Profile:

Jinan Xilang Machine Co.,ltd is a professional Manufacturer specializing in researching and producing Extrusion machinery,Industrial microwave drying and sterilizing equipment and related ancillary equipment.The Company is located in Jinan,the spring city of Shandong. With the strong design strength,advanced producing technology and rich manufacturing experience,the company`s products get good comments from domestic and abroad customers.

Our main products include machinery and equipment for pasta system, corn flakes system, breakfast cereal system, baby food system, corn puff snacks system, fried pellets system, fortified nutrition rice system,soy nuggets system, pet food system , fish feed system , various type drying oven system, corn meal milling system etc.

Our machines have been exported to many countries of Asia, America, Africa, Europe etc. So Don't hesitate to contact us. Xilang team from pre -service to after-service will show your choice is worth it.

8.FAQ

Q: Are you a trade company or a manufacturer?

A: we are a manufacturer, welcome to visit our factory and check the machines.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-35 days if the goods are not in stock, we could discuss before contract.

Q: Could you supply all the parameters about the machines?

A: Yes, we will supply all the parameters, price, layout drawing, factory design etc.

Q: What is your terms of payment ?

A: 30% T/T in advance ,70% balance before shippment after inspection.

Q: How about the after-service?

A: We will send 1 engineer to the buyer's factory for 7-14 days period installation and training to the operators.