Instant Artificial Nutrition rice production line

Brand :XI LANG

Product origin :Jinan, China

Delivery time :20days

Supply capacity : 100 sets per month

1. Low production cost, easy processing and production. Endow rice with a unique shape, taste and color, nutrition ratio science, easy to digest, adapt to the requirements of all kinds of people.

2. The production from flour to finished product is completed at one time, with high degree of automation, simple operation, moderate output, energy saving, small footprint and only one tenth of the investment of large equipment.

3. Its technology perfect, compact structure, novel design, stable and reliable performance, less investment, quick effect characteristics, especially suitable for small and medium-sized enterprises.

1.Product Description of Instant rice production line

Brief introduction:

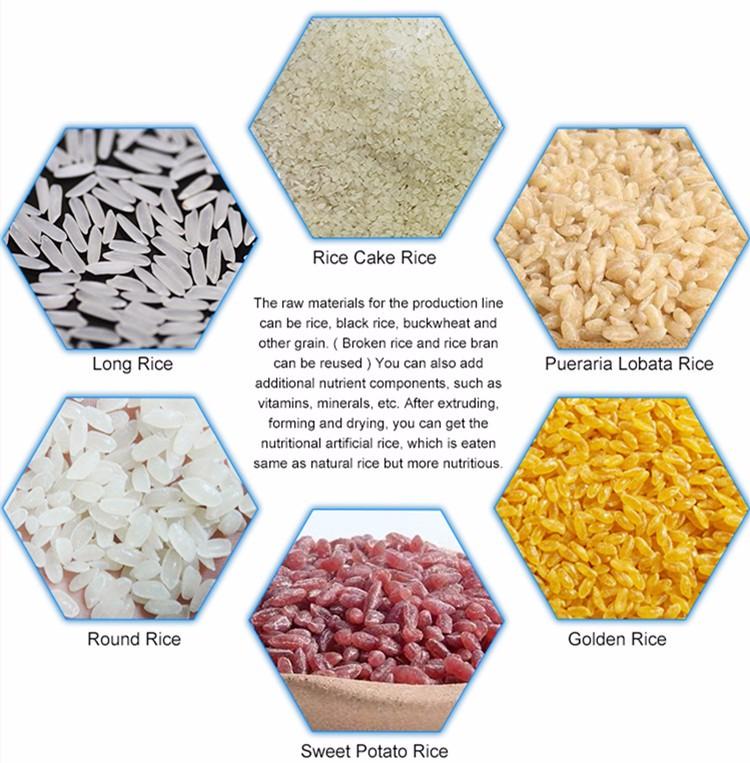

Nutritionan fortified rice produced by our fortified rice production line is finished rice made by adding some nutrients that are lacking or specially needed by the human body to ordinary rice. The nutritional fortification of rice contains a variety of vitamins, minerals and amino acids. Nutrient-enriched rice makes the rice nutrition more balanced, can guarantee consumers' basic nutritional needs including micronutrients, and gradually control and eliminate the two major malnutritions, insufficient nutritional intake and nutritional imbalance.

Raw materials:

Rice,black rice,buckwheat and other grains.

2.The technical specification of machine

Model | XL65-III nutritional rice processing line | XL70-II nutritional rice processing line | XL75-II nutritional rice processing line |

Installed power | 54kw | 60kw | 135.5kw |

Actual consumption power | 35kw | 40kw | 105kw |

Production capacity | 120-150kg/h | 160-200kg/h | 200-250kg/h |

Appearance size | 14000*1200*2200mm | 16000*1200*2200mm | 33000*1800*2500mm |

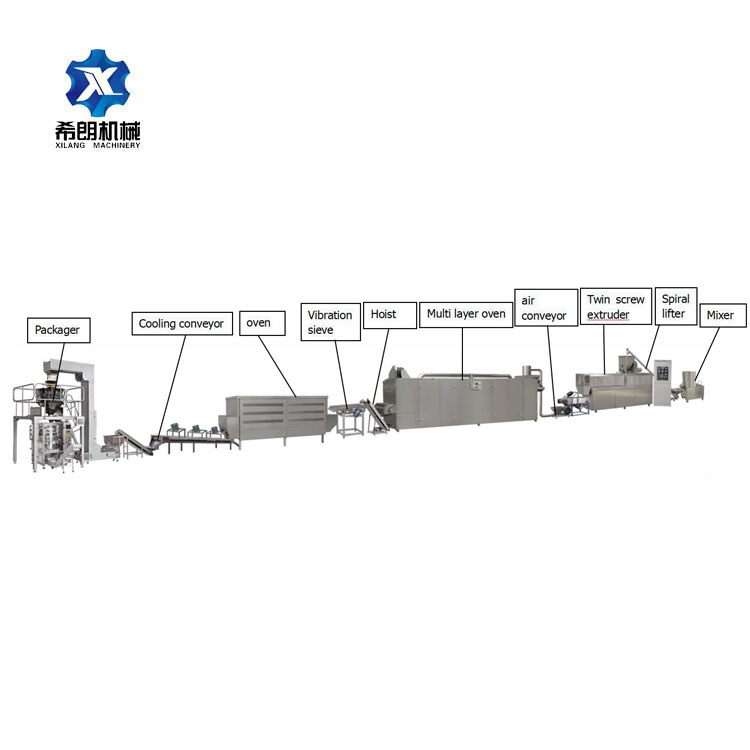

3.Processing flow and equipment configuration:

Processing flow:

raw material mixing - extrusion and granulating - cooling - drying - rolling sieve cooling - packaging

Equipment list:

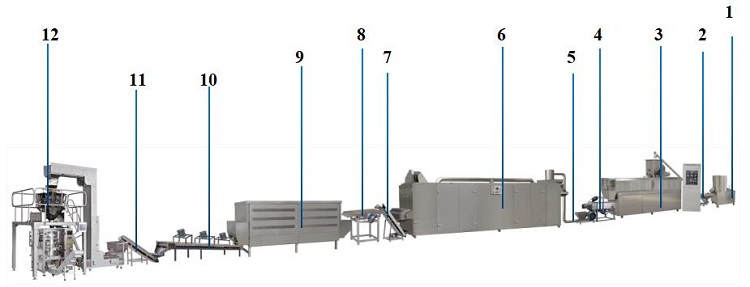

①Mixer→②Screw Feeder→③Twin Screw Extruder→④Vibrating Screen→⑤Air Conveyor→⑥Muti-layer Dryer→ ⑦Hoist →⑧Vibrating Screen→⑨High-temperature inflated dryer→⑩Cooling Conveyor→11.Hoist →12.Vertical Packing Machine

The composition of artificial rice making machine

No | Name | Function |

1 | Mixer | Mix all the raw materials (powder form) with water or other liquid additives |

2 | Screw Feeder | Convey the mixed materials to the extruder without any leaking,dusting and pollution |

3 | Twin screw extruder | Extrude and cook raw material into different size and shapes |

| 4 | Vibrating screen | it is maily used for material high humidity steam emitting and cooling,to prevent particles bonding. |

5 | Air conveyor | Transport the extruded materials into dryer. It has the characters of less energy consumption,high efficiency,no leakage of food transportation,no pollution etc. |

6 | Muti-layer Dryer | Bake and dry products. There are 3/5/7 layes inside,it can save space and energy. 304 stainless steel Net bag transfer frequency control. |

7 | Hoist | Transport the dried product to Vibrating screen |

8 | Vibrating screen | The product is dispersed and cooled by continuous vibration |

9 | High-temperature inflated dryer | High temperature secondary puffing for artifical instant rice,instant nutritionself-heating rice,porridge rice etc. |

10 | Cooling Conveyor | Cooling and conveying the finished artificial rice products |

11 | Hoist | Transport the final product to packing |

12 | Vertical Packing Machine | Pack artificial rice products automaticly and diversely |

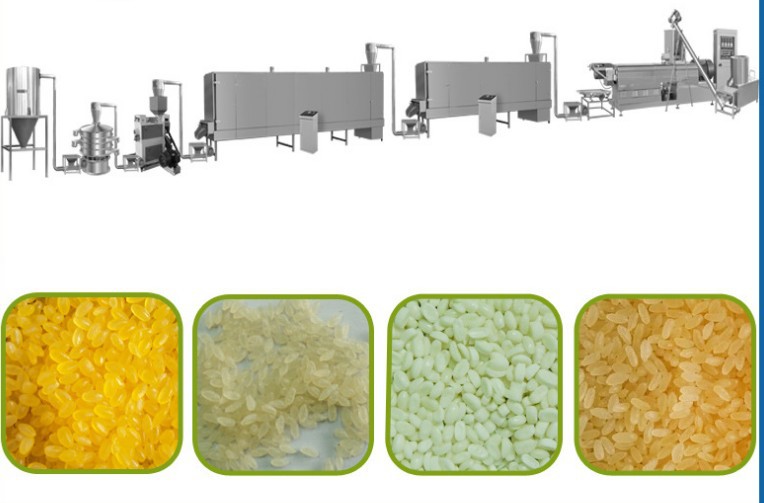

Finished Products

mix all the raw materials (powder form) with water or other liquid additives

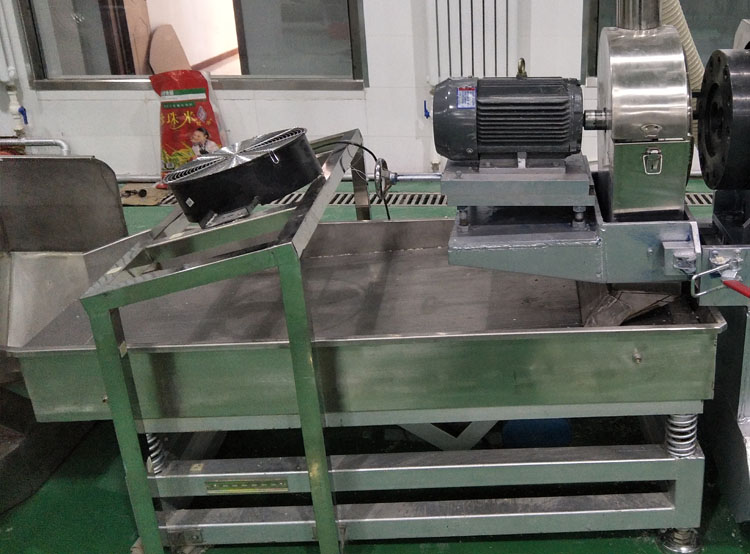

Screw Feeding machine: use the motor as the power screw conveying to ensure convenient and fast feeding.

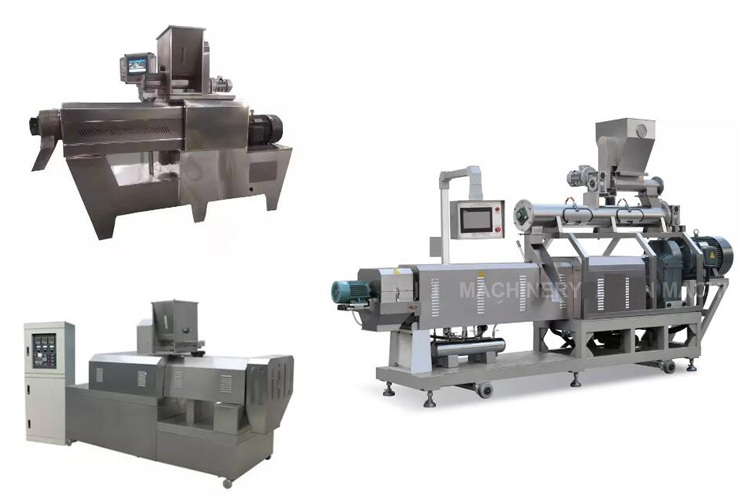

Twin screw extruder:

Through the screw, the structure of the raw material is broken under the high temperature and high pressure state to fully expand the nutritious rice in the shape of rice through the mold, and products of different shapes can be obtained by changing the mold.

Vibrating sieve: The ectruded nutritious rice particles contain a certain temperature and viscosity, they can evenly spread through the vibrating screen.

Hoist: transporting the feed to the oven, the height of the elevator is determined according to the oven, and an air conveyor can also be used.

Multi-layer oven:

the oven is mostly electric oven, the temperature is adjusted between 0-200 degrees through the control cabinet, the inside is stainless steel double-layer mesh bag, the baking time can be adjusted according to the speed, there are different layers stainless steel oven include three layers,five layers and seven layers.

4.Sample Photos:

5.Extruder Features:

1. The host adopts advanced frequency converter speed regulation technology, so that the equipment has strong power, more stable and electricity saving;

2. The screw adopts alloy steel nitriding treatment, longer life of the screw, individual equipment adopts building block combination structure, can be arbitrarily combined according to different needs;

3. Forced lubrication system to ensure that the transmission part of the equipment has a longer life;

4. Visual automatic temperature control system, to make the temperature control more intuitive, more parameters;

5. Screw with self-cleaning function, stop without removing screw cleaning;

6. Different screw and length-diameter ratio can meet different production processes;

6.Packaging and Shipping:

1)Inner packing: Stretch film

2)Outside packing: Standard export wooden cases

3)The package also can be according to customer requirements.

3)If you want to know the transportation cost:

by ship-please tell me your delivery port; by air-please tell me your airport name; by express-please tell me your detailed address(including zip code, house number, street, city, country).

7.Company Profile:

Jinan XiLang Machinery Co.Ltd, established in 2005, more than 16 years of experience in extrusion food machinery industry. Our products consist of single/double-screw extrusion snacks machine, breakfast cereal and corn flakes machine, fish feed machine, pet food machine, dog chew machine, fried food machine, etc. We can supply individual items of equipment or complete factory layouts and lines, which are custom-built to suit the requirements of customers. Most importantly, we also provide formulas, technology supports, machine inspection service, etc.

We have exported more than 40countries like USA, Neitherland, France, Italy, India, Malaysia, Brazil, Russia, Singapore, Thailand, etc.

Jinan XiLang Machinery Co.Ltd offer complete solution, turnkey solution service. We can guarantee customers that the equipments fully meet the design requirements and achieve the perfect working condition..

8.FAQ

Q1: Are you a trade company or a manufacturer?

A1:We are a manufacturer,we have own factory and R&D department.

SGS has certified our company on site.welcome to visit our factory and check the machines.

Q2: How long is your delivery time?

A2: Generally it is 5-10 days if the goods are in stock. or it is 20-35 days if the goods are not in stock, we could discuss before contract.

Q3: Could you supply all the parameters about the machines?

A3: Yes, we will supply all the parameters, price, layout drawing, factory design etc.

Q4. Can you provide food or feed formula?

A4: We can provide basic formula for produce the food etc.

And help customer to produce new products according to customer’s formula.

Q5: What is your terms of payment ?

A5: 30% T/T in advance ,70% balance before shippment after inspection.

Q6: How about the after-service?

A6: We will send 1 engineer to the buyer's factory for 7-14 days period installation and training to the operators.