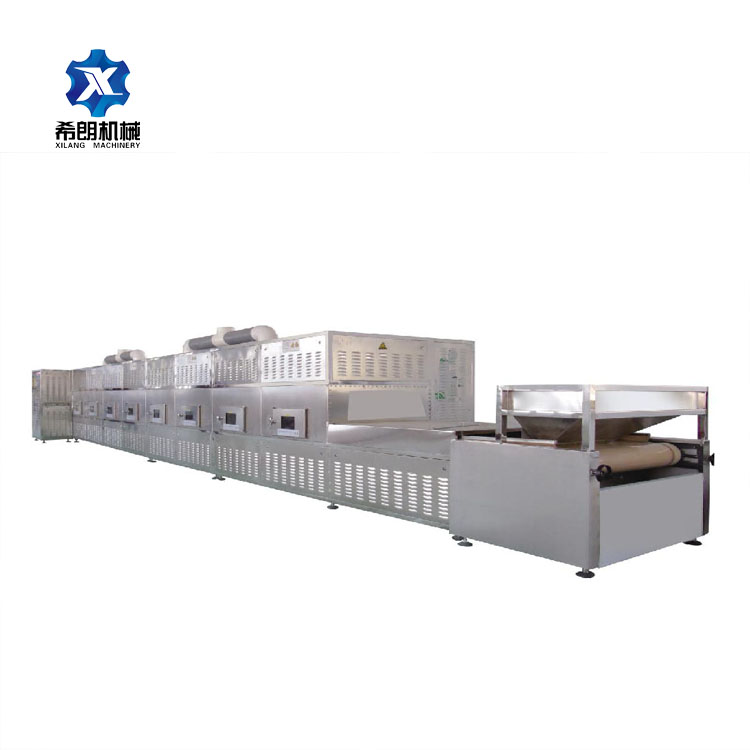

Tea Leaf Microwave Drying Machine Equipment

Brand :XI LANG

Product origin :Jinan,China

Delivery time :20days

Supply capacity : 100 sets per month

Large-scale microwave drying equipment adopts brand-new microwave drying technology and equipment. Able to achieve pollution-free and uniform drying of materials,

At the same time, the drying temperature can be greatly reduced. In addition, the drying speed is usually increased by several times, the production efficiency is greatly improved, and the drying energy consumption

Usually reduced by more than 50%, fully meet the national environmental protection standards, and ultimately achieve safe, clean and efficient production.

Tea Leaf Microwave Drying Machine Equipment

Applications:

1.chemical material,medicine tablet or pill,such as watered pills,water-honey bolus,honeyed bolus,condensed pill and Tibetan pill,etc.

2.all kinds of teas,herbs, flowers, green leaves,etc.

3.various dried meat, like beef, pork, chicken,duck, fish etc.

4.powder for various material,such as spices, other food additives.

5.agricultural products,such as china date,nuts,grains,peanut,etc

6.snack food, fruit seeds, grains, peanuts, chips,etc.

Brief introduction:

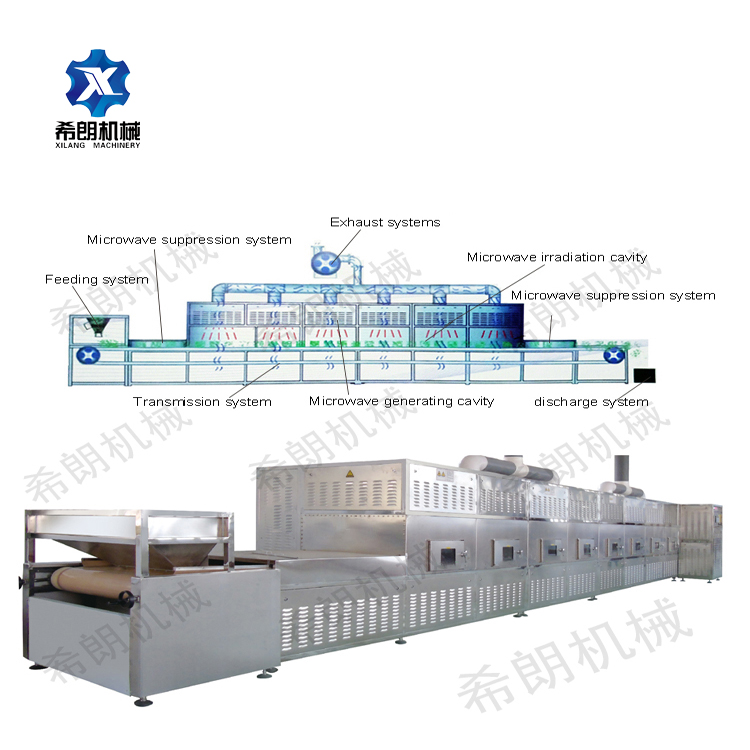

Microwave drying is a heating method in which electromagnetic wave is used as heating source and the drying material itself is heating body. Due to the characteristics of microwave drying, microwave drying has the advantages of uniform drying, good quality, fast speed, high efficiency and good compatibility with other drying methods.

Microwave sterilization is accomplished under the combined action of thermal effect and electromagnetic force effect. On the one hand, the high frequency alternating electric field of microwave causes the bacteria to be heated and the nucleus is concentrated and dissolved, and the cells shrink and disintegrate, so as to achieve the purpose of killing bacteria.

Microwave drying sterilization machine is used for drying and sterilizing various kinds of food---snack food, agricultural products, fish slice, slice dried meat, bean products, instant noodles, fast food, dried fruit, tea, herbs, karaoke powder, fruit and vegetable in the form of powder, granules, slice, etc.

It maximizes the preservation for activity of materials and vitamins, color & nutrition of food. It makes the goods drying and sterilizing at the same time.

The technical specification of equipment

Model | Microwave frequency | Microwave power/kw | Input power/kw | Input voltage | L*W*H (m) | Dewaterability | Remark |

XL-20KWFL | 2450±30 | 20 | 25 | 380V | 8m×1.0m×1.8m (H) | 20kg | air cooling |

XL-40KWSL | 2450±30 | 40 | 46 | 380V | 8.5m×1.5m×2.0m (H) | 40kg | water cooling |

XL-60KWSL | 2450±30 | 60 | 68 | 380V | 13.5m×1.5m×2.0m (H) | 60kg | water cooling |

XL-80KWSL | 2450±30 | 80 | 90 | 380V | 17.4m×1.5m×2.0m (H) | 80kg | water cooling |

XL-100KWSL | 2450±30 | 100 | 115 | 380V | 19.5m×1.5m×2.0m (H) | 100kg | water cooling |

Compared with the traditional process, the microwave drying process reduces energy consumption by more than 40%, provides more than 50 times the power, and revolutionizes production costs.

Microwave Drying Sterilization Machine brings the company's lasting core competitiveness and is deeply trusted by the majority of users. The company researched and developed a variety of models according to GMP, FDA, QS certification and other standards.

After-sales service:

1. Provide you with consultation on the market, equipment, technology, raw and auxiliary materials, packaging, etc.

2. Assist you in equipment selection, process design, and plant optimization layout.

3. According to your product, you can design a compensation plan for changes in raw materials and carry out on-site demonstrations. Provide various basic formulas.

4. Special design, manufacture and application test can be carried out according to your needs, and targeted training can be provided.

5. Design a reasonable packaging and transportation plan and transportation for you, and send technicians to install and debug and train personnel.

6. The equipment is guaranteed for one year, long-term preferential, and spare parts are supplied.

7. Undertake the design and processing of similar imported equipment parts.

Packing and transportation

1.Packaging: All machines are packaged according to international standard export package.Inside is covered by plastic film, outside is wooden case.

Company Profile:

Jinan Xilang Machine Co.,ltd is a professional Manufacturer specializing in researching and producing Extrusion machinery,Industrial microwave drying and sterilizing equipment and related ancillary equipment.The Company is located in Jinan,the spring city of Shandong. With the strong design strength,advanced producing technology and rich manufacturing experience,the company`s products get good comments from domestic and abroad customers.

Our main products include machinery and equipment for pasta system, corn flakes system, breakfast cereal system, baby food system, corn puff snacks system, fried pellets system, fortified nutrition rice system,soy nuggets system, pet food system , fish feed system , various type drying oven system, corn meal milling system etc.

Our machines have been exported to many countries of Asia, America, Africa, Europe etc. So Don't hesitate to contact us. Xilang team from pre -service to after-service will show your choice is worth it.

FAQ

1. What's the pre-sale service of your company for microwave drying machine ?

Related machines’s technical parameter will be supplied to customer.

1.1 Layout can be provided in advance basing on customer’s factory size.

1.2 General formulation can be offered according to customer’s material cost,.

1.3 Machine could be customization.

1.4 Professional suggestion for Market, machines, processing , materials, packing.

1.5 Suggesting professional ship agent or helping book ship according to customer situation.

2. What's the after-sale service of your company for microwave drying machine?

2.1. Allocation chart will be offered as the buyer’s request .

2.2. Professional Operation manual will be supplied after shipment.

2.3. One year warranty support, life time maintenance with cost price.

2.4. Free easy broken spare parts will be sent together with machines .

2.5. First installation supports.

2.6. Worker training supports.

3. what about spare parts after sale service for micromave drying machine?

We can offer the wearing parts all the time together with changing video.

4 Are you manufacturer or trading company?

We are the manufactuer,welcome to visit us.

5 Whether you could make your brand on the products?

Yes, we could print your logo on both products and packages.

6 What is the terms of payment?

30% T/T in advance, the balance before goods leave our company.