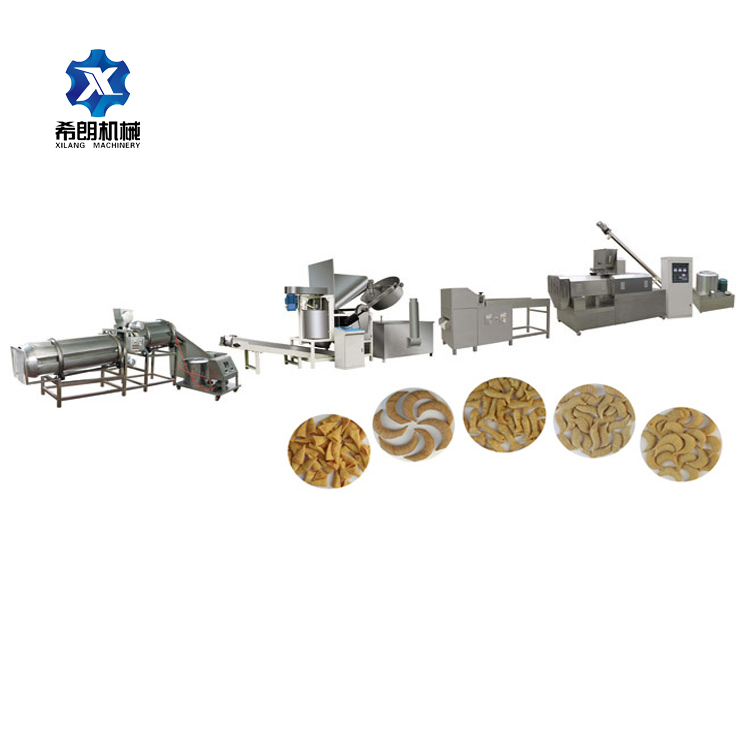

Fried Flour Sticks Bugles Snack Food Processing Machine Production Line

Brand :XI LANG

Product origin :Jinan,China

Delivery time :20days

Supply capacity : 100 sets per month

1. Xilang fried and puffed food production line has a unique technology, reasonable configuration, high degree of automation, stable performance, no need to configure the boiler, set refining and extrusion molding as one

2. Adopt advanced double-screw extrusion technology, forced transmission, can be processing raw materials to choose wider, mold transformation can transform the form and size of the product infinitely

3. Bugles snack processing machine can produce triangles, gourd shapes, small fish cakes and so on

Fried Flour Sticks Bugles Snack Food Processing Machine Production Line

The equipment of the rice cracker production line has a wide range of raw materials, diverse product shapes, and flexible configuration. Its advantages are mainly reflected in the same power. The production efficiency is significantly higher than similar models. It is stable, reliable, and easy to operate. It has excellent long-term continuous operation performance. It is suitable for puffing processing of different materials and has a longer service life.

The rice cracker production line of Jinan Xilang Machinery Co., Ltd. is a puffed food equipment developed according to the needs of domestic and foreign markets. Its operating performance, product quality, and process taste have reached the level of the same industry. The production line is simple to operate, easy to learn and understand, and its parameters Control and process flow can better ensure the stable quality of processed products.

The technical specification of crispy chips bugles process Line

Model | XL65-II | XL70-II | XL75-I | XL85-II | XL95-I |

Main machine power(kw) | 22 | 30/37/45 | 55/75/90 | 110/132 | 132/160 |

Actual consumption power (kw) | 20 | 25/30/35 | 40/70/85 | 105/128 | 128/155 |

Production capacity (kg/h) | 120-150 | 150-220 | 300-500 | 600-800 | 800-1200 |

Appearance size (mm) | 2600x850x1800 | 2900x850x1800 | 4200x1000x2300 | 5600x1100x2500 | 6500x1200x2800 |

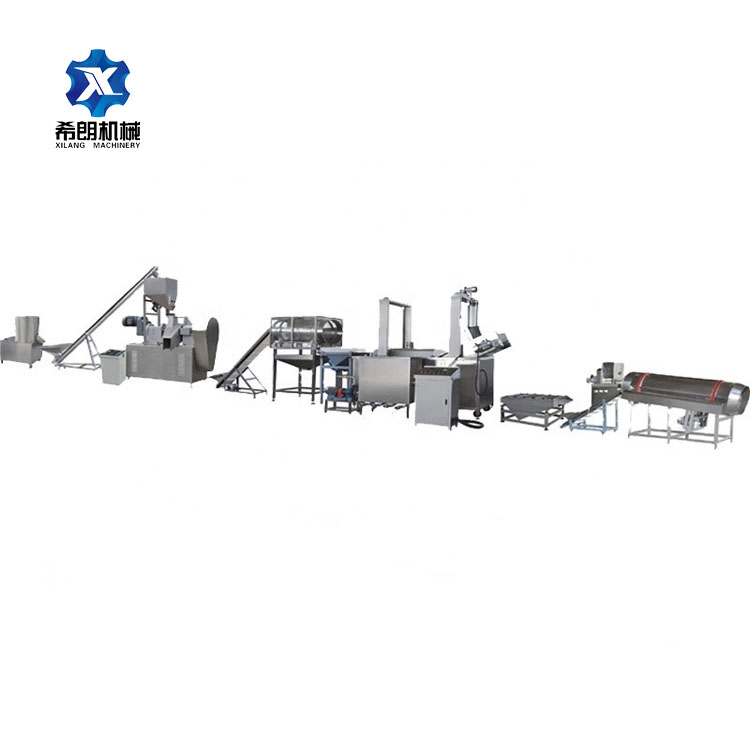

The process flow of the fryer equipment production line:

Production process: raw material mixing → extrusion puffing → shaping and cutting → frying → oiling → seasoning → packaging (flexible equipment configuration)

1. The process flow of the rice cracker production line:

Raw material preparation → powder mixing → puffing machine → traction cutting → automatic frying → seasoning → packaging

2. Frying rice cracker production equipment configuration:

Flour mixing machine → puffing machine → traction shaping and cutting machine → automatic frying machine → octagonal tube → packaging machine

Puffed rice cracker production equipment configuration:

1. Powder mixing machine: high efficiency, uniform mixing, improving the production efficiency of the equipment, and improving the mixing quality. It is used for mixing food powdery raw materials with a small amount of liquid raw materials.

2. Feeding machine: convey the mixed raw materials to the feeding hopper of the extruder through a screw conveyor.

Provides work efficiency, reliable quality and durability, and the raw materials are completely free from moisture, pollution, foreign matter, and loss during the feeding process, realize the self-transportation of the feeding process, avoid the danger of high-altitude feeding, and reduce labor intensity. Improve production efficiency, increase the angle, easy to clean, simple maintenance, etc.

Fast feeding, labor saving, safe and reliable

3. Twin-screw extruder: adopts frequency conversion speed regulation technology, more powerful power, more stable operation, more power saving, forced lubrication system to ensure longer life of the transmission part, visual automatic temperature control system, self-cleaning function, etc. It is more stable when expanding the product.

Separate control cabinet control

The twin-screw machine is composed of a feeding system, an extrusion system, a rotary cutting system, a heating system, a transmission system, and a control system.

The main engine motor is a special Lijiu motor with an insulation class of F.

The protective cover is detachable, and the baffle is used to effectively separate the belt and the material to prevent the material from sticking to the belt.

The screw has a self-cleaning function, and there is no need to disassemble the screw for cleaning when it stops.

4. Cutting machine: frequency conversion speed regulation, output can be adjusted, and it can be matched with the host in the early stage.

The front section is a shaping and flattening roller, and the rear section is a former

Both the former and the roller are made of Teflon, which effectively prevents adhesion.

Molding the product, mainly used in triangles, flakes and other products

5. Fryer: It integrates the functions of frying, oil throwing and conveying, with compact structure and complete functions.

The frying process is centrally controlled by the control cabinet, which runs automatically and has a high degree of automation.

Only a temperature control system and a reasonable stirring device can ensure the frying effect of the food.

High-efficiency electric heating system, stable temperature control effect, environmental protection and clean.

There are two options of automatic and manual, simple and flexible operation.

6. Seasoning line: The lifting equipment has the obvious advantages of large conveying capacity, stable and reliable operation, and long life.

The rotor pump is powerful, but it can be used for products with higher viscosity and consistency

Controllable spray temperature

Used for spraying syrup, chocolate, etc.

Stainless steel smooth roller

Ensure uniform spraying by rolling

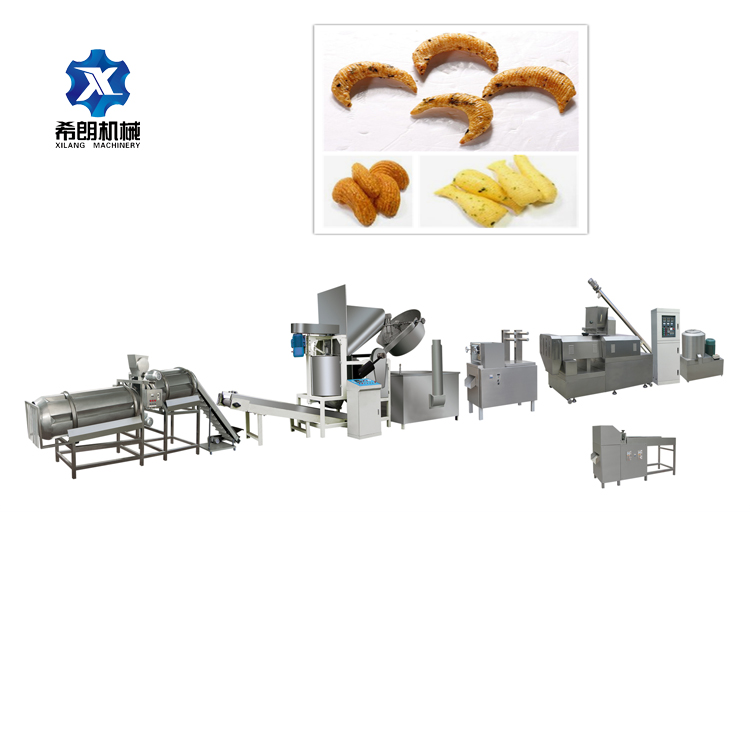

Sample pictures

Service

☆Provide you with professional consultation on the market, equipment, technology, raw and auxiliary materials, packaging, etc.

★Assist you in equipment selection, process design, plant optimization layout, and door-to-door service if necessary.

☆ Compensation schemes for material changes can be designed for your products, and live demonstrations can be carried out. Provide various basic formulas.

★Special design, manufacture and application test can be carried out according to your needs, and targeted training can be provided.

☆Design a reasonable packaging and transportation plan for you, agent transportation, and send technicians to install and debug and train personnel.

★The equipment is guaranteed for one year, long-term preferential, and spare parts are supplied.

☆Undertake the design and processing of similar imported equipment parts.

Packing & deliverying

Company profile

Jinan Xilang Machine Co.,ltd is a professional Manufacturer specializing in researching and producing Extrusion machinery,Industrial microwave drying and sterilizing equipment and related ancillary equipment.The Company is located in Jinan,the spring city of Shandong. With the strong design strength,advanced producing technology and rich manufacturing experience,the company`s products get good comments from domestic and abroad customers.

Our main products include machinery and equipment for pasta system, corn flakes system, breakfast cereal system, baby food system, corn puff snacks system, fried pellets system, fortified nutrition rice system,soy nuggets system, pet food system , fish feed system , various type drying oven system, corn meal milling system etc.

Our machines have been exported to many countries of Asia, America, Africa, Europe etc. So Don't hesitate to contact us. Xilang team from pre -service to after-service will show your choice is worth it.