pet dry food processing machine manufacturers

Brand :Xilang

Product origin :Jinan China

Delivery time :15days

Supply capacity :20 units per month

1.High efficiency, low consumption, easy to operate and maintain.

2.The pet dry food processing machines' performance and products quality reach to the most advanced level in the world.

3.We provide customers with basic formulas and professional formulas for pets of different ages.

1.Brief introduction of pet dry food processing machines

The pet dry food processing machines adopt advanced extruding technology. the main twin screw extruder machine can suit various raw materials, such as corn flour, fish mill, meat mill etc. By changing molds The pet dry food processing machines can produce various shapes and sizes of feed pellets for different pets at different ages.

2.The technical parameters of pet dry food processing line

Model | 65twin screw extruder line(dry type) | 70 twin screw extruder line(dry type) | 85 twin screw extruder line | 75 twin screw extruder line | 95twin screw extruder line |

Main machine power | 22kw | 30kw | 37/45 | 55/75 | 90/110 |

Drying type | gas/electric | gas/electric | gas/electric/steam | gas/electric/steam | gas/electric/steam |

Production capacity | 120-150kg/h | 150-180kg/h | 350-500kg/h | 450-600kg/h | 1000-1200kg/h |

Appearance size | 12000x4000x2200mm | 13500x4000x2200mm | 16500x4000x3200mm | 18500x4000x3200mm | 21000x4000x3200mm |

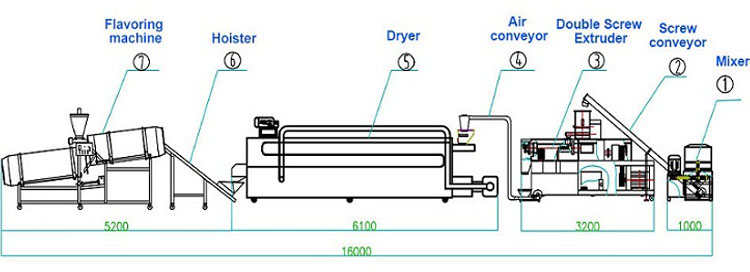

3.The flow chart of pet dry food processing line

Raw material preparation→mixing→conveying→extrusion→conveying→drying→oil spraying→flavoring→cooling→screening→packaging

4.The composition of pet dry food production line:

NO. | Machine Name | Function |

1 | Mixer | Mix the raw material and other additives fully. |

2 | Screw conveyor | Screw turns to make the raw material convey in the sealed tube,no leaking and no pollution |

3 | Twin screw Extruder | The material is fully matured under high temperature and pressure, through the outlet mold expansion, form foods of various shapes. |

4 | Air Conveyor | conveys the pet food pellets relying on the wind-force from the blower |

5 | Muti-layer Dryer | Used to drying pet food, Net belt running speed can be controlled |

6 | Hoist | Convey the dried pet food pellets into flavoring machine |

7 | Double rolls flavoring line | The stainless steel flavor feeder is used to spray flavor to the drum |

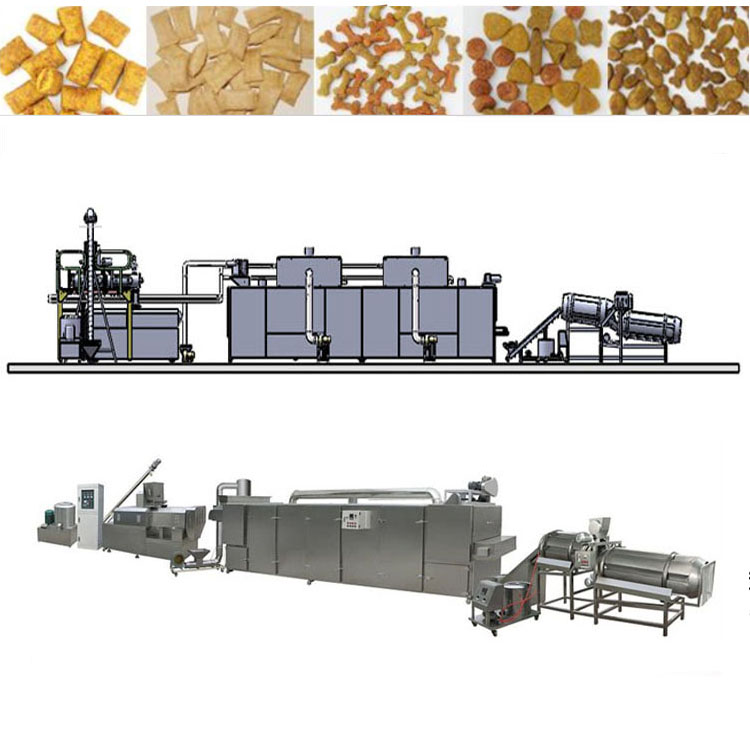

5.Sample photos of pet dry food pellets

6.The main twin screw exruder's features of of pet dry food processing line

1).Alloy (38CrMoAL) screw made by nitriding process, high strength and wear-resting. Self-cleaning ability, no need to discharge or clean the barrel and screw when roasting or replacing of materials.

2).Adopting speed adjusted converter on feeding system, extrusion system and cutting system.Food grade stainless steel twin screw feeding machine, stable materials feeding in the whole food process.

3).Gearbox with automatic lubrication function, extending gear life.

4).World famous brand Siemens main motor, guaranteeing good quality

5).Barrel with water-cooled circulation, raw materials not only for corn/rice, also for wheat flour/starch with high viscosity. Different moisture-extrusion temperature ratio, whole-expanded and half expanded as different type of products.

6).Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

7.Packing and Shipping

Packaging: daub coal oil on the surface to protect the machine from moisture, Then cover with plastic film. Finally pack them with wooden case.

8.Certificates and Projects

9.Company Profiles