Automatic Nutritional Baby Food Powder Extruder Making Machine

Brand :XI LANG

Product origin :Jinan,China

Delivery time :20days

Supply capacity : 100 sets per month

1. Xilang nutrition powder production line with rice, corn, beans and other grains as raw materials.After extrusion, drying, crushing, mixing, can produce a variety of nutritional powder, such as baby rice noodles, sesame paste, soybean powder, etc.It can be easily mixed with a wide variety of ingredients and nutrients.

2. The nutritional powder production line starts from the feed, and the process is automatically completed, with simple operation, no dust leakage, sanitation and energy saving.Accurate parameter control can ensure the stability of the product quality.

Automatic Nutritional Baby Food Powder Extruder Making Machine

Brief introduction of nutrition powder making machine:

Nutrition powder production equipment can be a variety of grains and stable performance of various nutrients as raw materials, after dry extrusion puffed starch paste denaturation, reduce the shortcomings of polymer condensate easy absorption in raw materials, making the nutritional rice expansion equipment produced nutrition rice noodles, has the special superior performance of human body absorption and nutrition.And with less space, in a relatively short time, can let the user absorb a variety of nutrients needed by the body, to supplement the human energy.Especially suitable for the elderly who need to simplify the absorption process, children who need to absorb nutrients quickly, and white-collar workers who need to shorten the preparation time as far as possible.

Raw materials of nutrition baby powder making machinery:

Corn flour, rice flour, corn grits and other grains flour etc

Voltage and frequency of nutrition baby powder making machinery

Three phases: 380V/50Hz, Single phase: 220V/50Hz (China standard)

We can make it according to customers' local voltage according to different countries

The technical specification of baby nutrition powder production line

Model | XL65-II | XL70-II | XL75-I | XL85-II | XL95-I |

Main machine power(kw) | 22 | 30/37/45 | 55/75/90 | 110/132 | 132/160 |

Actual consumption power (kw) | 20 | 25/30/35 | 40/70/85 | 105/128 | 128/155 |

Production capacity (kg/h) | 120-150 | 150-220 | 300-500 | 600-800 | 800-1200 |

Appearance size (mm) | 2600x850x1800 | 2900x850x1800 | 4200x1000x2300 | 5600x1100x2500 | 6500x1200x2800 |

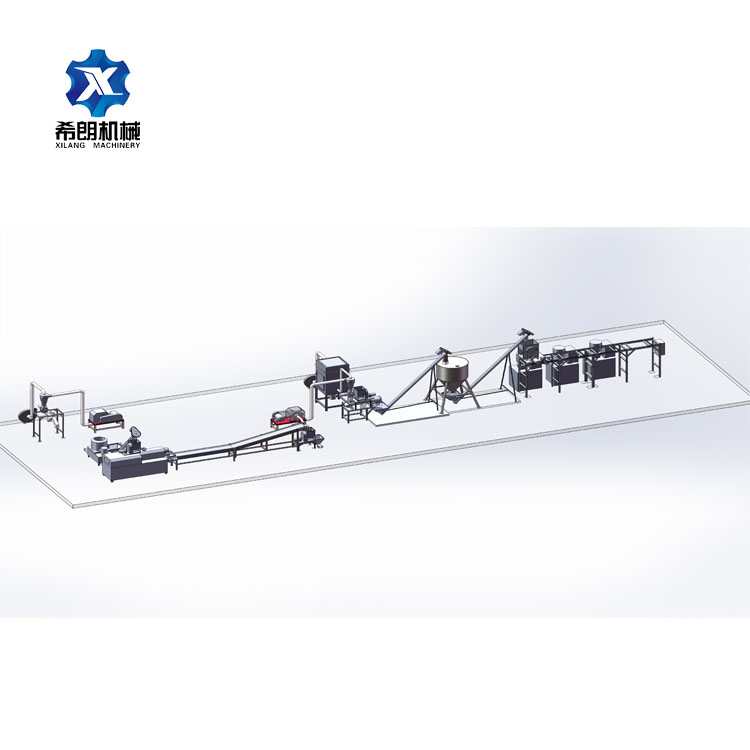

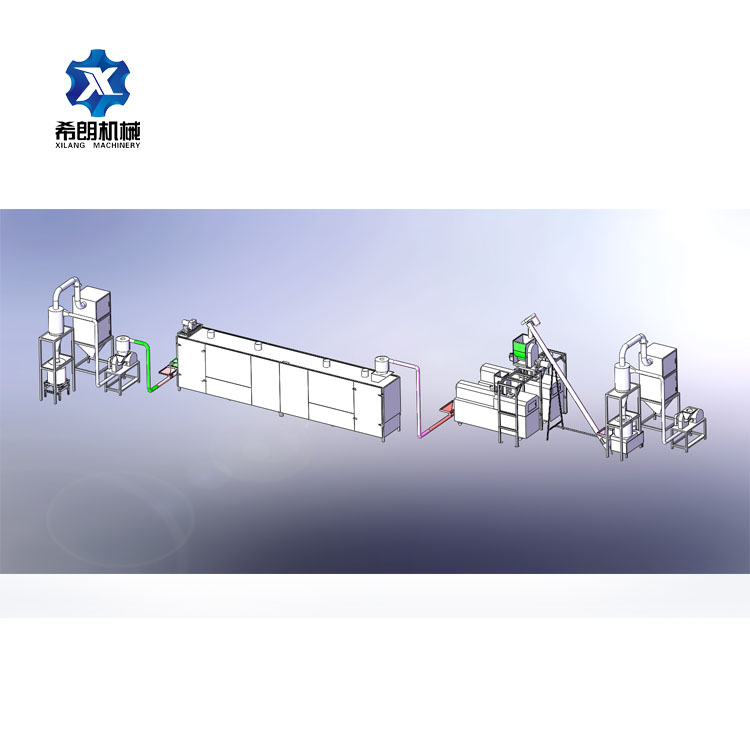

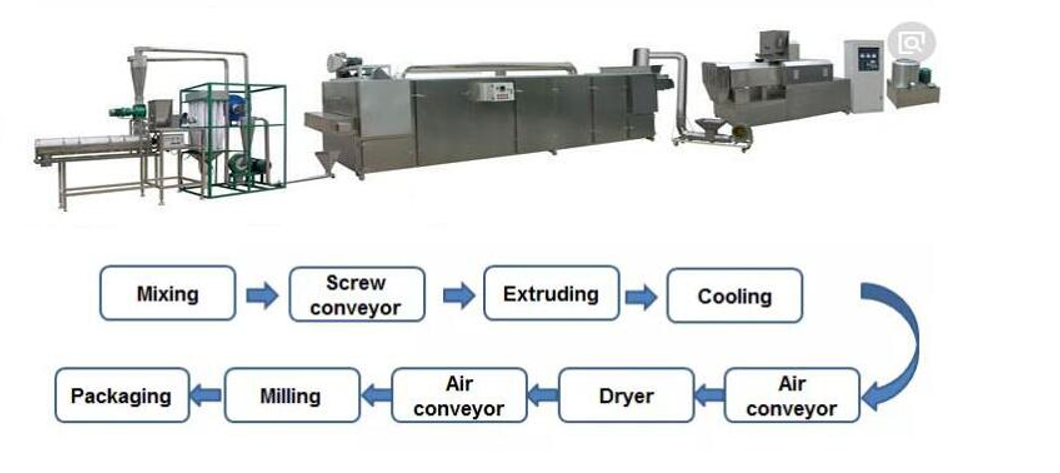

Process flow and equipment configuration of nutrition powder extruding line

Process flow: raw material preparation → mixing powder → transfer → quality adjustment → extrusion expansion-delivery-drying (crushing packaging)

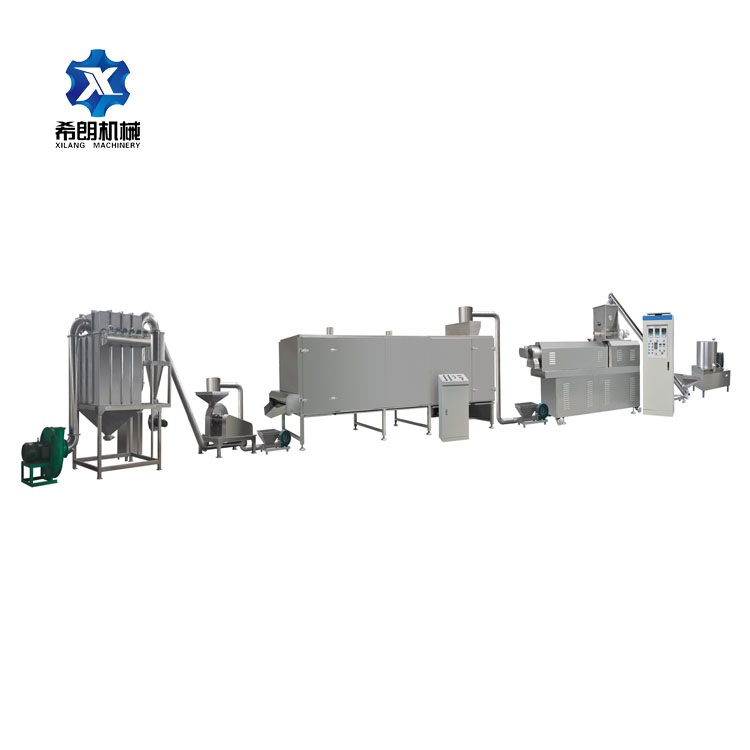

Equipment configuration: powder mixer → screw feeder → double-screw extruder → air transmitter → five-layer eight-meter oven (crushing package)

Introduction to the configuration of nutritional rice noodle production line;

1. Crusher; generally, cast steel crusher is used.

2. Mixing machine: It can mix 50 kg of raw materials at a time, and the equipment is easy to maintain and easy to use.

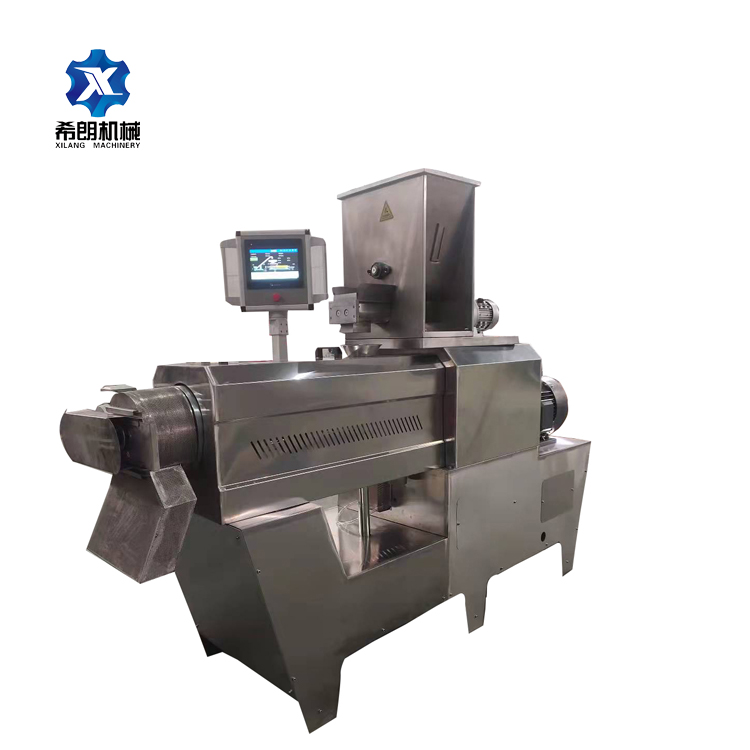

3. Extruder: The extruder is our company’s main equipment, which is distinguished according to the diameter and length of the extruder screw. The 65/70/75 twin-screw machine can produce a variety of puffed foods including nutritional powder, the 85-type twin-screw extruder mainly produces breakfast cereals, porridge products and fried foods, the production of nutritional powder, and the 95-type twin-screw extruder Mainly used as feed and puffed powder products.

4. Air conveyor: Air conveyor is equipped with different types of air conveyors according to the output size. The main function is to transport materials. ** It has a small area. The placement can be linked to the oven according to the size of the site;

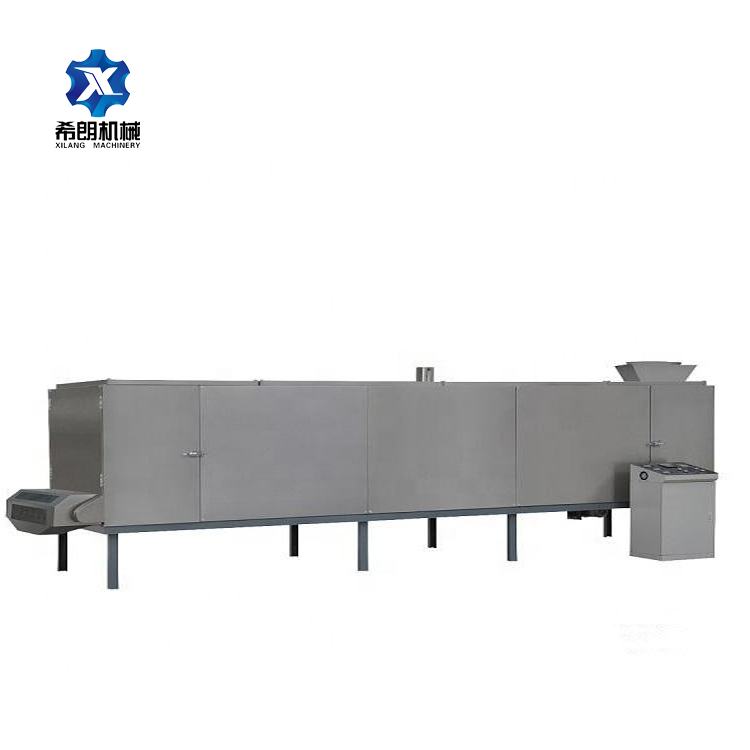

5. Oven. Length and width can be customized according to actual needs. Conventional products have multiple models, five meters three layers, five meters five layers, eight meters three layers, eight meters five layers, eight meters seven layers, ten meters five layers, ten meters Meter seven layers, heating methods are divided into electric heating type, oil heating type, gas heating type.

6. Crushing unit; including raw material pipeline, pulverizer, powder pipeline, scatterer, closed air device, induced draft fan, dust collector. There are two types of crusher: cast steel type and stainless steel type. The exterior of the cast steel type is all stainless steel packaging. The number of meshes can be adjusted by changing the sieve. The mixer is composed of a mixer and a feeder. The feeder is controlled by a frequency conversion and its speed is adjustable. It mainly adds some other grain materials to it.

7. Microwave sterilization oven; sterilize the product effectively to prevent various harmful intestinal bacteria from killing.

Sample picture

Packing & Delivery

1.Packaging: All nutrition baby powder making machine are packaged according to international standard export package.Inside is covered by plastic film, outside is wooden case.

Customer & Exhibition

Customer & Exhibition

Company profile

Jinan Xilang Machine Co.,ltd is a professional Manufacturer specializing in researching and producing Extrusion machinery,Industrial microwave drying and sterilizing equipment and related ancillary equipment.The Company is located in Jinan,the spring city of Shandong. With the strong design strength,advanced producing technology and rich manufacturing experience,the company`s products get good comments from domestic and abroad customers.

Our main products include machinery and equipment for pasta system, corn flakes system, breakfast cereal system, baby food system, corn puff snacks system, fried pellets system, fortified nutrition rice system,soy nuggets system, pet food system , fish feed system , various type drying oven system, corn meal milling system etc.

Our machines have been exported to many countries of Asia, America, Africa, Europe etc. So Don't hesitate to contact us. Xilang team from pre -service to after-service will show your choice is worth it.

FAQ

1. What's the pre-sale service of your company for nutrition baby powder making machinery ?

Related machines’s technical parameter will be supplied to customer.

1.1 Layout can be provided in advance basing on customer’s factory size.

1.2 General formulation can be offered according to customer’s material cost,.

1.3 Machine could be customization.

1.4 Professional suggestion for Market, machines, processing , materials, packing.

1.5 Suggesting professional ship agent or helping book ship according to customer situation.

2. What's the after-sale service of your company for nutrition baby powder making machinery ?

2.1. Allocation chart will be offered as the buyer’s request .

2.2. Professional Operation manual will be supplied after shipment.

2.3. One year warranty support, life time maintenance with cost price.

2.4. Free easy broken spare parts will be sent together with machines .

2.5. First installation supports.

2.6. Worker training supports.

3. what about spare parts after sale service for nutrition baby powder making machinery?

We can offer the wearing parts all the time together with changing video.

We are the manufactuer,welcome to visit us.

Yes, we could print your logo on both products and packages.