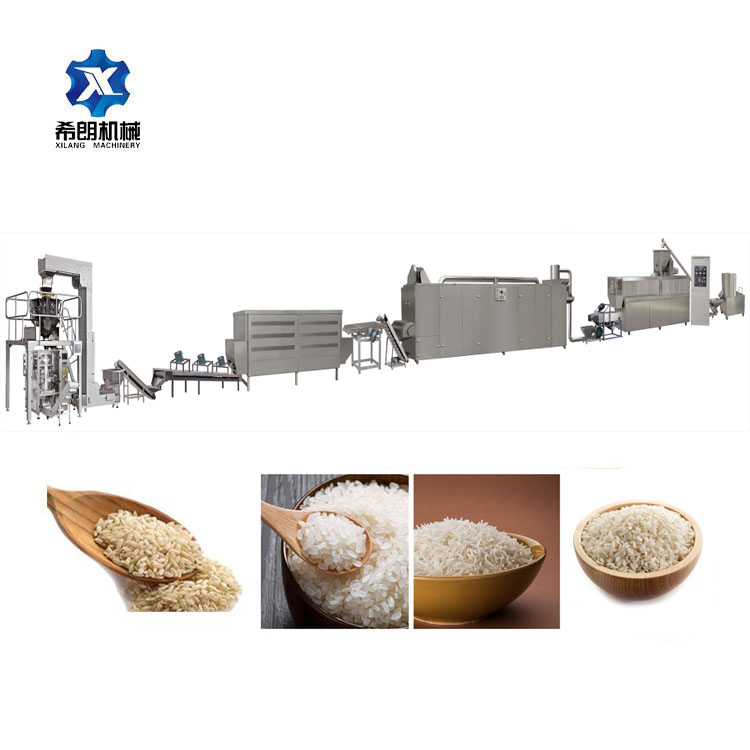

Nutrition artificial rice making machine

1.Xilang artificial rice production line has compact structure, small occupation area, new design, mature technology, moderate capacity and only one tenth of the investment of large equipment.

2.Short production process and low energy consumption. The final product artificial rice is a convenient and healthy food popular with the mass market.

3. The machine is quick and self-cleaning, precise parameter control, High degree of automation, easy to operate.

1.Product Description:

Brief introduction of nutrition artificial rice making production line

Xilang nutrition artificial rice making production line adopts rice, black rice, buckwheat and other grains (broken rice, rice bran can be reused) as raw materials, Adds vitamins, minerals, amino acids and hydrous materials such as fruits and vegetables, after extrusion, molding, drying, can get artificial nutrition rice,The finished product has the same appearance as natural rice. This artificial rice can be mixed with natural rice prior to cooking as usual and can be eaten directly

Raw Materials: rice,broken rice,rice power, corn, millet, wheat, oats, buckwheat, bean, starch etc.

Finished Products:

Shapes:By changing the dies, same machine can produce various shapes rice,long rice, short rice, thin rice, etc.

Nutrition:By adding different nutrition, common rice and broken bran rice is made into nutritious rice to supply rice nutrition to people especially the people in poor region.

Capacity: 150kg/h, 300kg/h, 550kg/h, 1ton/h etc.

Voltage:

Three phases 380V/50Hz, Single phase 220V/50Hz in China.

we can make it according to customers' Local voltage.

2.The technical specification

Model | XL65-III nutritional rice processing line | XL70-II nutritional rice processing line | XL75-II nutritional rice processing line |

Installed power | 54kw | 60kw | 135.5kw |

Actual consumption power | 35kw | 40kw | 105kw |

Production capacity | 120-150kg/h | 200-300kg/h | 300-400kg/h |

Appearance size | 14000*1200*2200mm | 16000*1200*2200mm | 33000*1800*2500mm |

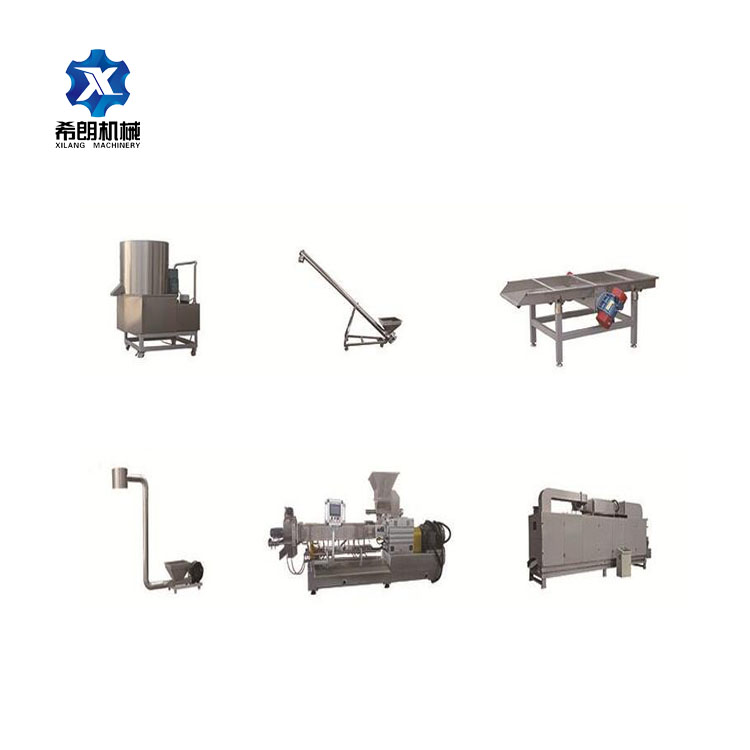

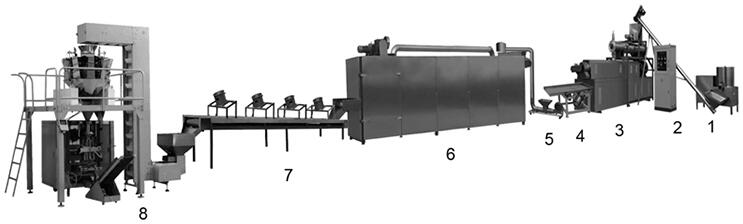

3.Flow Chart of artificial rice extruder machine:

Whole Processing Line

Material mixing with water→ material conveying → extruding → drying → cooling → Storage

Equipments List:

①Mixer→②Screw Feeder→③Twin Screw Extruder→④Vibrating Screen→⑤Air Conveyor→⑥Muti-layer Dryer →⑦Cooling Conveyor→⑧Packing Machine

No | Name | Function |

1 | Mixer | Mix all the raw materials (powder form) with water or other liquid additives |

2 | Screw Feeder | Convey the mixed materials to the extruder without any leaking,dusting and pollution |

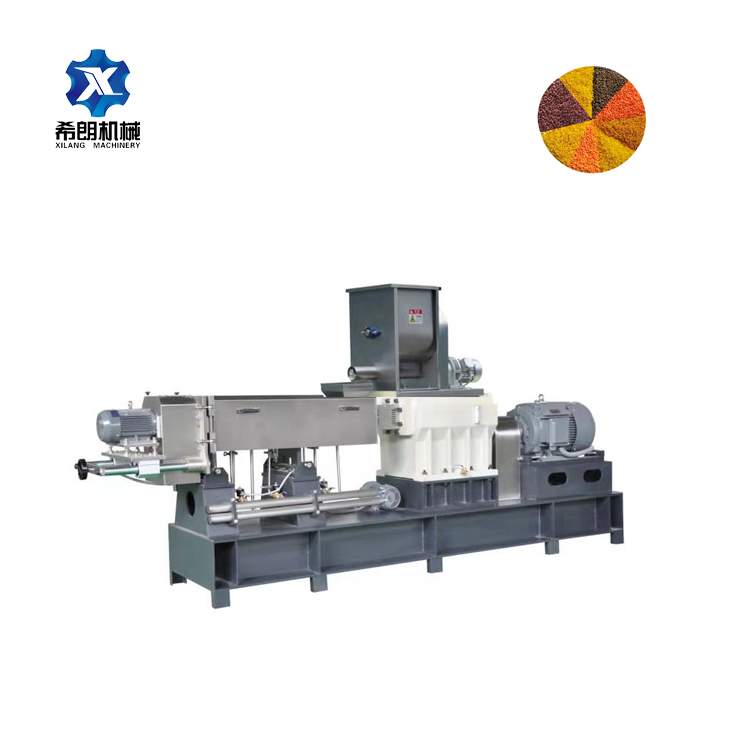

3 | Twin screw extruder | Extrude and cook raw material into different size and shapes |

4 | Vibrating screen | The screen shakes continuously by the vibrate motor, which effectively prevent the extruded products from sticking together,and cool them down. |

5 | Air conveyor | Transport the extruded materials into dryer. |

6 | Muti-layer Dryer | Bake and dry products.There are 3/5/7 layes inside,each layer is 5-12 meters long, it can save space and energy. The heating source can be electric, gas, steam and fuel. |

7 | Cooling Conveyor | Cooling and conveying the finished artificial rice products to the the packing machine. |

8 | Vertical Packing Machine | Pack artificial rice products automaticly and diversely |

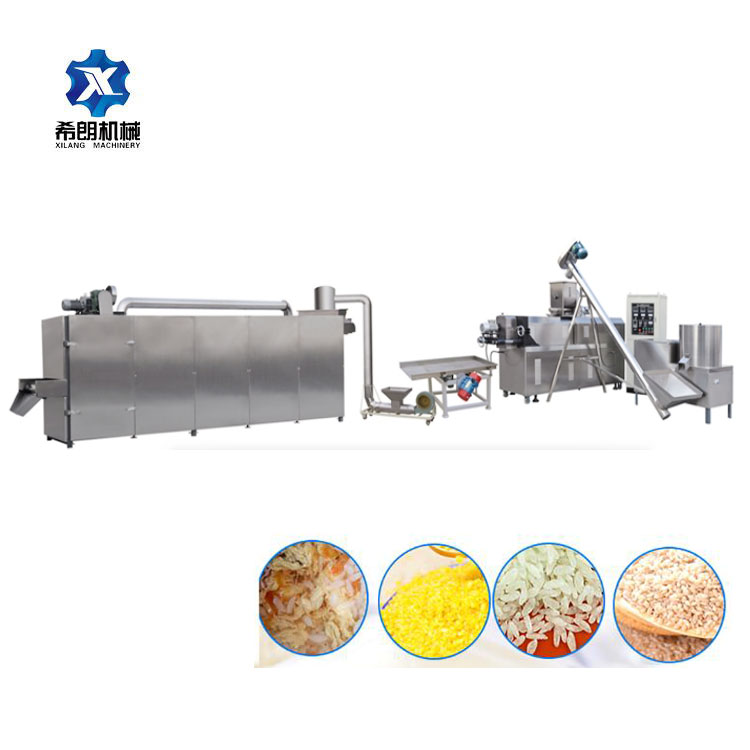

Finished Machines:

4.Sample photos:

This machine line can produce the Artificial rice, nutrition rice, fortified rice, man made rice, gold rice, instant rice etc.

By changing the extruder mold, variety rice shape and size can be produced to meet the different market demand.

5.Extruder Features:

1.The main extruder adopts frequency speed controlling with high automation and stable per-formation.

6.Packing and Delivery:

Packing Details

1.Inner packing: Stretch film

2.Outside packing: Standard export wooden cases

3. The package also can be according to customer requirements.

7.Company Profile:

Jinan Xilang Machine Co.,ltd is a professional Manufacturer specializing in researching and producing Extrusion machinery,Industrial microwave drying and sterilizing equipment and related ancillary equipment.The Company is located in Jinan,the spring city of Shandong. With the strong design strength,advanced producing technology and rich manufacturing experience,the company`s products get good comments from domestic and abroad customers.

Our main products include machinery and equipment for pasta system, corn flakes system, breakfast cereal system, baby food system, corn puff snacks system, fried pellets system, fortified nutrition rice system,soy nuggets system, pet food system , fish feed system , various type drying oven system, corn meal milling system etc.

Our machines have been exported to many countries of Asia, America, Africa, Europe etc. So Don't hesitate to contact us. Xilang team from pre -service to after-service will show your choice is worth it.

8.FAQ

Q1: Are you a trade company or a manufacturer?

A:We are a manufacturer,we have own factory and R&D department.

SGS has certified our company on site.welcome to visit our factory and check the machines.

Q2: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-35 days if the goods are not in stock, we could discuss before contract.

Q3: Could you supply all the parameters about the machines?

A: Yes, we will supply all the parameters, price, layout drawing, factory design etc.

Q4. Can you provide food or feed formula ?

A: We can provide basic formula for produce the food etc.

And help customer to produce new products according to customer’s formula.

Q5: What is your terms of payment ?

A: 30% T/T in advance ,70% balance before shippment after inspection.

Q6: How about the after-service?

A: We will send 1 engineer to the buyer's factory for 7-14 days period installation and training to the operators.