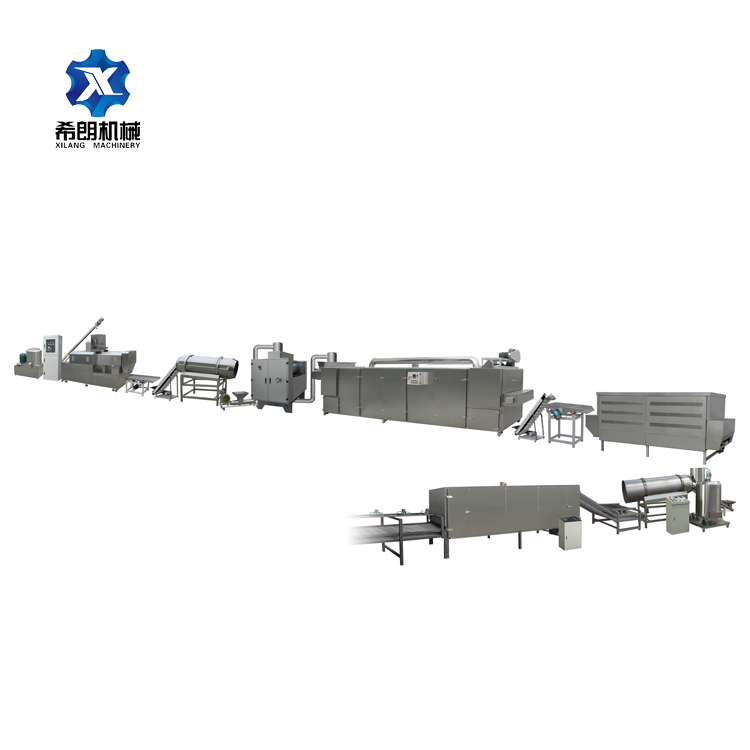

Instant Breakfast Cereal Corn Flake Production Line

Brand :XI LANG

Product origin :Jinan,China

Delivery time :20days

Supply capacity : 100 sets per month

1. Process: the cooking method of granular materials is changed to the extrusion method of powder materials, and the advanced twin-screw extruder is used for fully kneading, cooking and cutting, pressing and forming of the grain powder after adding water.

2. Technology: high degree of automation, whole process control, easy to operate. Assembly line continuous production, high efficiency, low noise, energy saving and stability.

3. Products: the breakfast cereal production line of corn flakes, cereal, cheerie, puffed rice and other breakfast cereals retain the nutritional ingredients of cereals in good condition; The product can be mixed with hot coffee, hot milk, or eaten as a snack.

1.Introduction to Instant Breakfast Cereal Corn Flake Production Line:

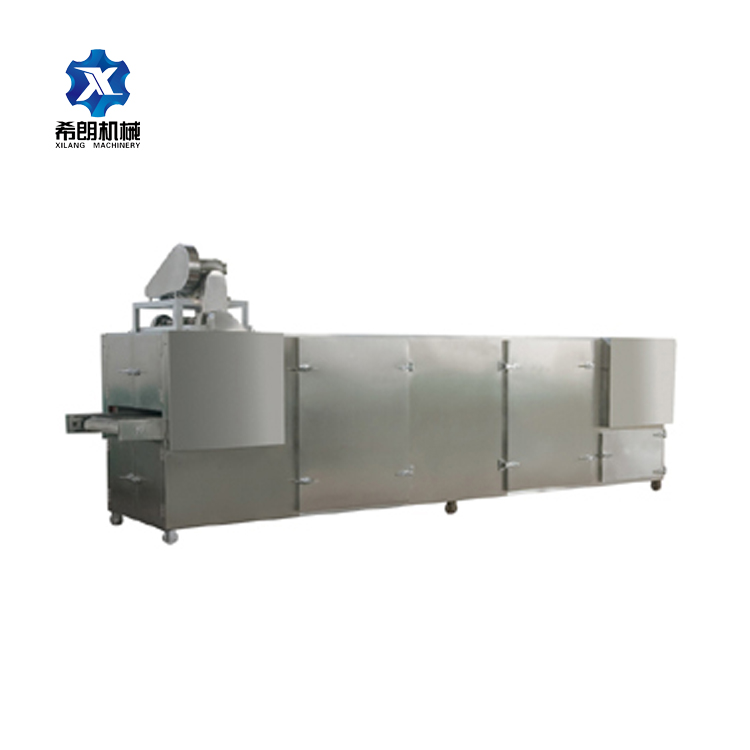

Instant Breakfast Cereal Corn Flake Production Line use corn flour and other grain flours as their raw materials to produce various type of breakfast cereals and corn flakes. The whole produce line is made up of mixing,extrudering, flaking, drying, high temperature baking ,flavoring and cooling. Just by changing the dies or choosing suitable production process, different shapes breakfast cereals can be produced. The breakfast corn flakes production line is highly automatic and high efficiency. All the machines choose the famous band motors and best accessories for installation.

2.Flow chart of Instant Breakfast Cereal Corn Flake Production Line:

Mixer - screw conveyor- Twin-screw extruder -Sifter-Air conveyor -Flaking machine -Air conveyor - Three-layer oven - Hoister -Microwave Oven -Melting sugar machine -Sprayer sugar-Hoister -Roller - Hoister - Five-layer oven- Cooing machine

3. Technical Parameter of Instant Breakfast Cereal Corn Flake Production Line

Here is main introduction for the breakfast corn flakes production line technical parameter, welcome to contact with us for detail information.

Model | XL65 | XL70 | XL85 | XL90 |

Main Power | 22kw | 30kw | 45kw | 110kw |

Drying Method | Electric or Steam | Electric or Steam | Electric or Steam | Electric or Steam |

Capacity | 120-150 kg/h | 150-180 kg/h | 400-500 kg/h | 1000-1200 kg/h |

4. Corn flakes and breakfast cereal produced by Instant Breakfast Cereal Corn Flake Production Line

5. Twin screw extruder function

5.1.1.The main extruder of breakfast corn flakes production line is made up of feeding system, heating system, extrusion system and cutting system. The main system of breakfast corn flakes production line adopts frequency speed with high automation controlling.

5.1.2.The screws of breakfast corn flakes production line are made of the special alloy steel (38CrMoAl)which has the advantage of durable usage, high pressure,and longer life.

5.1.3.The forced lubrication system of breakfast corn flakes production line can guarantee the equipment transmission life longer.

5.1.4.Auto-temperature control system and self-cleaning of breakfast corn flakes production line makes it more convenient.

5.1.5.corn flakes manufacturing equipments has the widest range of applications and can produce different products with different equipment and models

6.Company Information

Jinan Xilang Machine Co.,ltd is a professional Manufacturer specializing in researching and producing Extrusion machinery,Industrial microwave drying and sterilizing equipment and related ancillary equipment.The Company is located in Jinan,the spring city of Shandong. With the strong design strength,advanced producing technology and rich manufacturing experience,the company`s products get good comments from domestic and abroad customers.

Our main products include machinery and equipment for pasta system, corn flakes system, breakfast cereal system, baby food system, corn puff snacks system, fried pellets system, fortified nutrition rice system,soy nuggets system, pet food system , fish feed system , various type drying oven system, corn meal milling system etc.

Our machines have been exported to many countries of Asia, America, Africa, Europe etc. So Don't hesitate to contact us. Xilang team from pre -service to after-service will show your choice is worth it.

After-sales service:

1. Provide you with consultation on the market, equipment, technology, raw and auxiliary materials, packaging, etc.

2. Assist you in equipment selection, process design, plant optimization layout, and door-to-door service if necessary.

3. According to your product, you can design a compensation plan for changes in raw materials and carry out on-site demonstrations. Provide various basic formulas.

4. According to your needs, special design, manufacture and application tests can be carried out, and targeted training can be provided.

5. Design a reasonable packaging and transportation plan and transportation for you, and send technicians to install and debug and train personnel.

6. The equipment is guaranteed for one year, long-term preferential, and spare parts are supplied.

7. Undertake the design and processing of similar imported equipment parts.