Industrial Fried Instant Noodles Making Machinery

Brand :XILANG

Product origin :Jinan,Shandong

Delivery time :20 days

Supply capacity :100 sets per month

1. Xilang small instant noodle production line has novel design, compact structure, perfect technology and stable and reliable performance. Moderate production capacity, small footprint, small investment.

2. The mini instant noodle making machine from flour to finished product is completed at one time, with high degree of automation and easy to learn.

3. The mini instant noodle processing machine has some advantages: short rehydration time, good elasticity, smooth and transparent, the quality of corrugated instant noodles can be comparable with that of traditional large-scale equipment products.

1.Industrial Fried Instant Noodles Making Machinery Introduction

The small-scale instant noodle production line has advance technology, compact structure, novel design, stable and reliable performance. Weight Instant noodle produced by this line can be adjusted from 30g to 100g . According to the heating energy, the equipment is divided into electric, steam and combustion type (oil, natural gas).

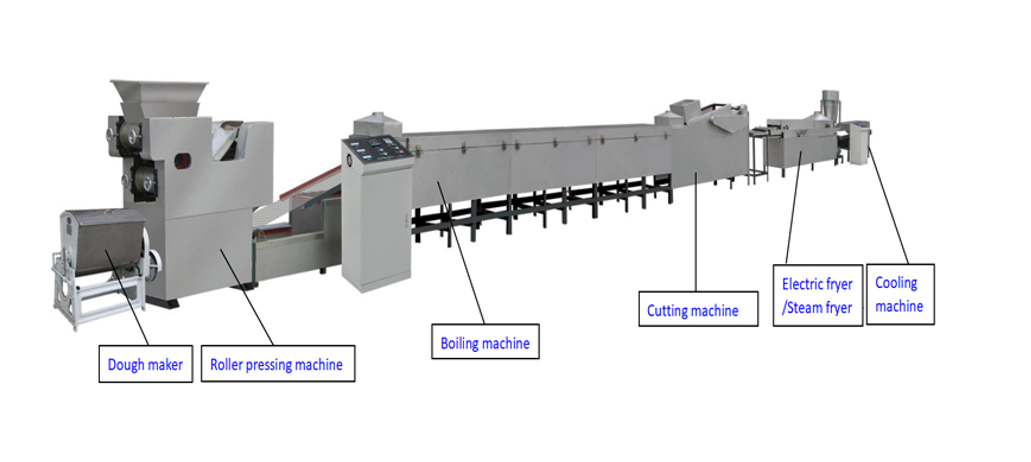

2 The flow chart of mini instant noodle making machine

mixing dough-forming-steaming-cutting-boxing-frying-cooling-packaging.

3 Raw material of mini instant noodle making machine:wheat flour

4 Voltage of mini instant noodle making machine

Three phases :380 V/50 Hz, Single phase: 220 V/50 Hz in china, we can make it according to customers' local voltage in different countries.

6 The technology specification of mini instant noodle makig machine

Model | Installed power | Steam pressure | Working width | Production capacity | Appearance size |

Electric XFX-III | 154kw | 1.5kg/cm² | 210mm | 11000pcs/8h | 26000x700x1500mm |

Steam XF-III | 4.2kw | 6kg/cm² | 210mm | 11000pcs/8h | 26000x700x1500mm |

7.Instant noodle making machine Main features

1) The size of instant noodles can be adiusted easily .

2) pressing & shapping machine , cutting machine and frying machine are all frequency control .

3) Rolling pressing design make the noodles springy .

4) Adopt good quality and food-grade stainless steel , which is longer service life and neatness .

5) Longer frying length to ensure good cooking and better taste of instant noodles .

6) Cooling conveyor is special designed with oil filtering function .

7) High automation and accurate control systerm to save labor cost and improve the quality of final products .

8.Sample picture as a reference

Package & transportation

1.Packaging: All mini instant noodle production line are packaged according to international standard export package.Inside is covered by plastic film, outside is wooden case.

Our services

a.) Design: All the machines are elaborately designed by our mechanical engineers who are rich of

experience in this.

b.) Processing & Assembling: Parts processing, assembly, testing are based on standard test.

c.) Trial Run: Each machine has to be tested before its deliver.

e) Spare parts: provide

Company profile

Jinan Xilang Machine Co.,ltd is a professional Manufacturer specializing in researching and producing Extrusion machinery,Industrial microwave drying and sterilizing equipment and related ancillary equipment.The Company is located in Jinan,the spring city of Shandong. With the strong design strength,advanced producing technology and rich manufacturing experience,the company`s products get good comments from domestic and abroad customers.

Our main products include machinery and equipment for pasta system, corn flakes system, breakfast cereal system, baby food system, corn puff snacks system, fried pellets system, fortified nutrition rice system,soy nuggets system, pet food system , fish feed system , various type drying oven system, corn meal milling system etc.

Our machines have been exported to many countries of Asia, America, Africa, Europe etc. So Don't hesitate to contact us. Xilang team from pre -service to after-service will show your choice is worth it.