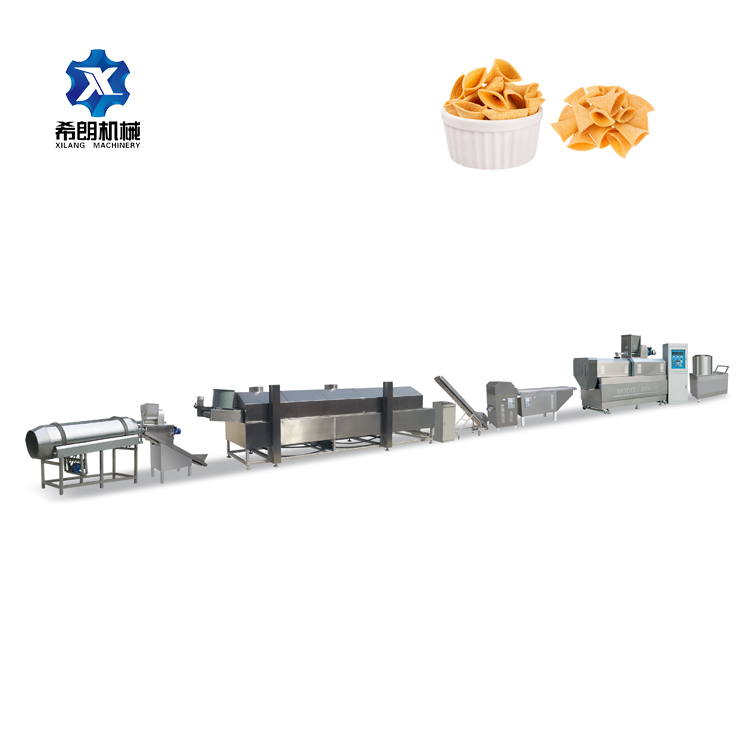

Industrial factory Fried Bugles Corn Chips Snacks Food Making Equipment

Brand :XI LANG

Product origin :Jinan,China

Delivery time :20days

Supply capacity : 100 sets per month

1 bugles snack making machines are made by stainless steel, this line is with reasonable design and with high automation;

2 the screws of puff frying snack production line are made by alloy steel, with building block system structure and self-cleaning function

3 Raw material of bugles snack making machine: Wheat flour, potato starch, potato flour, corn starch, cassava starch and so on.

4.After-sales Service Provided: Free spare parts, Field installation,Commissioning and training, Field maintenance and repair service, Video technical support, Online support.

Fried Snack Food Processing Machinery

The introduction of fried sanck food processing machinery

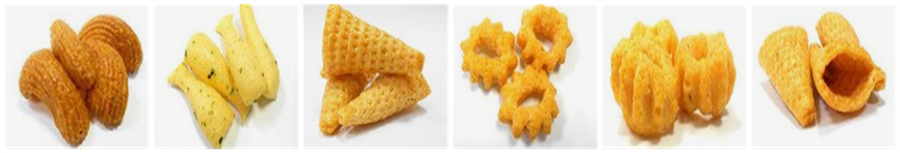

Bugles snacks food machines is a type of extruding food machine . It adopts corn, rice, wheat, oat, barley etc as ingredients to make puffs snack. Through friction of screw and barrel, the grains are cooked in the extruder Barrel. Forming is at the die face cutter. The product shape is determined by a combination of the die aperture, including ball, tube, stick, ring,Rice shape, fruit loop, star, wheel and flower etc.Snacks production line include mixer , screw conveyor , extruder , hoister , dryer , flavoring machine , packing machine .Fried snacks processing line can be used to produce rice crusts,chips,pizza rolls,doritos and so on.

The technical specification of extruded fried snack making machine

Model | 65 twin screw extruder line | 70 twin screw extruder line |

kw Installed power | 45kw | 55kw |

kw Actual consumption power | 30kw | 35kw |

Production capacity | 120-150kg/h | 180-250kg/h |

Appearance size | 12000x1600x2300 | 13000x1600x2300 |

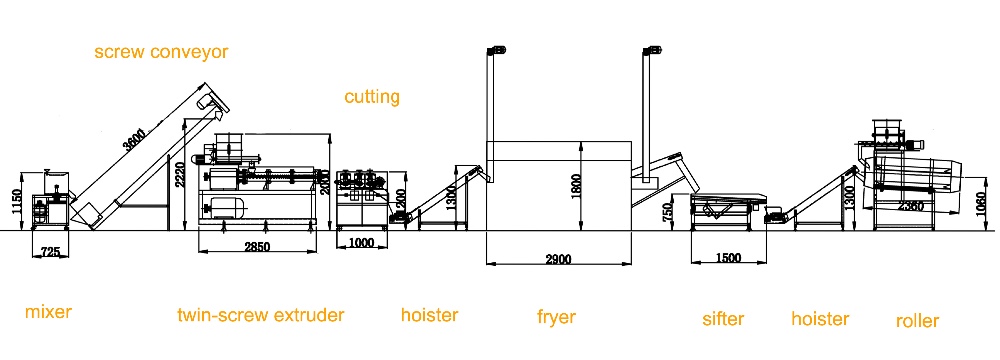

Bugles production line process flow: raw material preparation → powder mixing → conveying → extrusion and puffing → core injection → shaping and cutting → conveying → frying → oil injection → seasoning → packaging

Bugles chip production line equipment configuration: powder mixing machine → feeding machine → puffing machine → core injection machine → shaping and cutting machine → hoist → continous fryer → seasoning line → packaging machine

Process composition of automatic bugles snacks processing line:

1. Powder mixer: After mixing the raw materials, add a certain amount of water and mix well.

2. Feeding machine: The motor is used for screw conveying, and the mixed raw materials are conveyed to the feeding hopper of the extruder to ensure convenient and fast feeding.

3. Puffing machine: Choose different types of TSE type puffing hosts according to the output of the production line. The output can range from 100kg/h to 300kg/h. The raw materials can be corn flour, rice flour, flour, cereal flour, etc. as raw materials.

4. Core injection machine: The core material can be injected instantly when the hollow tube is produced by the extruder, which can inject peanut butter, chocolate sauce, syrup, etc.

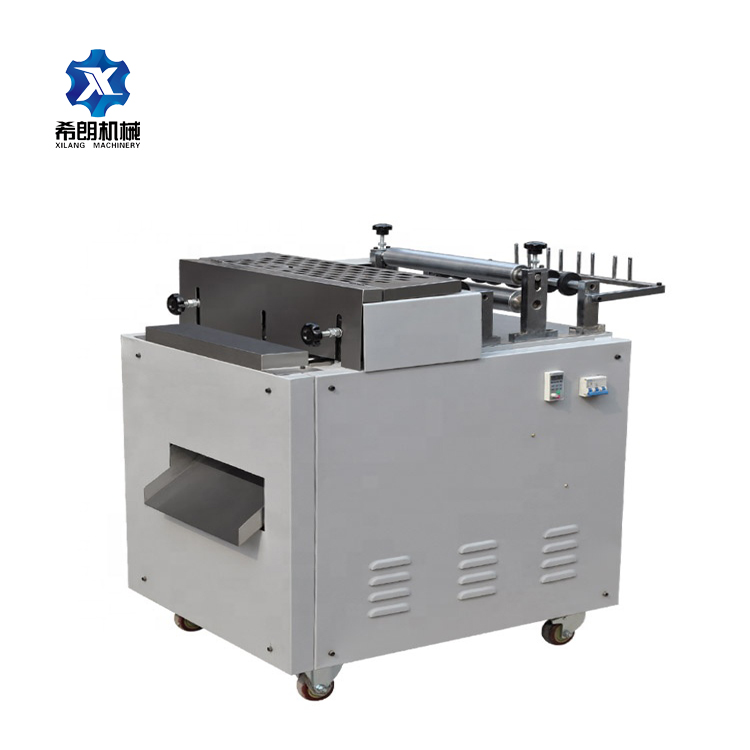

5. Shaping and cutting machine: Cut the rice crackers with the core material. The size of the rice crackers can be adjusted between 2cm-20cm.

6. Hoist: convey rice crackers to the oven.

7. Multi-layer oven: the oven is mostly electric oven, the temperature is adjusted between 0-200 degrees through the control cabinet, the inside is stainless steel double-layer mesh bag, the baking time can be adjusted according to the speed, and the main ingredient and core are adjusted by baking. The material penetrates to a certain extent to increase the taste, while reducing the moisture of the material and increasing the shelf life.

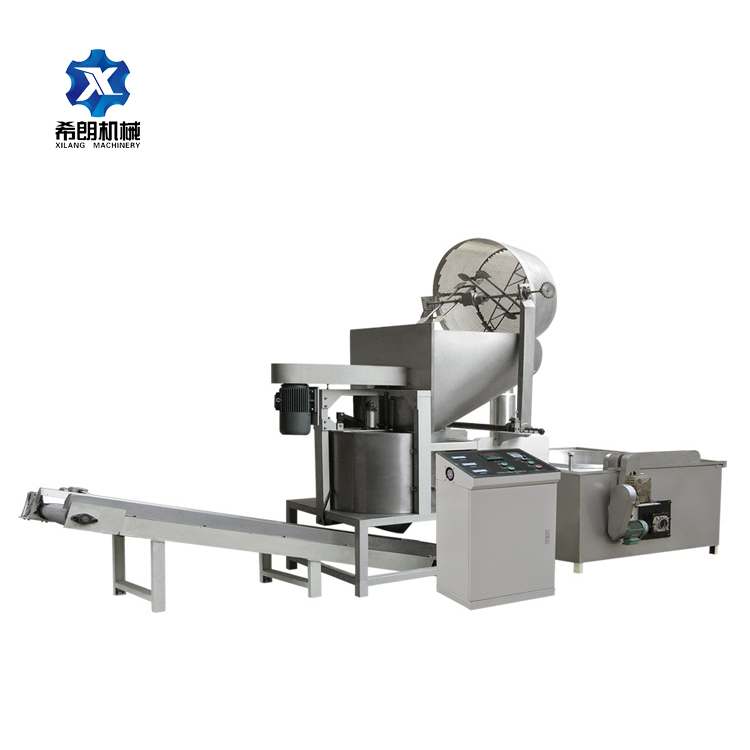

8. Seasoning line: There are octagonal tube, cylinder, lifting single drum, double drum seasoning line, which is configured according to the output and the nature of the product, and there are also oil spraying, sugar spraying and coating equipment.

Advantages of Xilang Machinery's twin-screw extruder

1. The host adopts advanced frequency converter speed regulation technology, which makes the equipment powerful, runs more smoothly and saves electricity;

2. The screw adopts alloy steel nitriding treatment, the life of the screw is longer, and individual equipment adopts a modular structure, which can be combined arbitrarily according to different needs;

3. Forced lubrication system to ensure that the transmission part of the equipment has a longer life;

4. Visual automatic temperature control system to make temperature control more intuitive and more parameters;

5. The screw has a self-cleaning function, no need to disassemble the screw for cleaning when it stops;

6. Different screws and length-to-diameter ratios can meet different production processes;

7. The main components of the extruder assembly line, the company's heavy equipment precision processing equipment, stable quality, low cost, preferential accessories

Sample picture

Packing &delivery

Packing &delivery

1.Packaging: All machines are packaged according to international standard export package.Inside is covered by plastic film, outside is wooden case.

Our Advantages

a.) Design: All the machines are elaborately designed by our mechanical engineers who are rich of

experience in this.

b.) Processing & Assembling: Parts processing, assembly, testing are based on standard test.

c.) Trial Run: Each machine has to be tested before its deliver.

d) Quality guarantee term: 1 year

e) Spare parts: provide

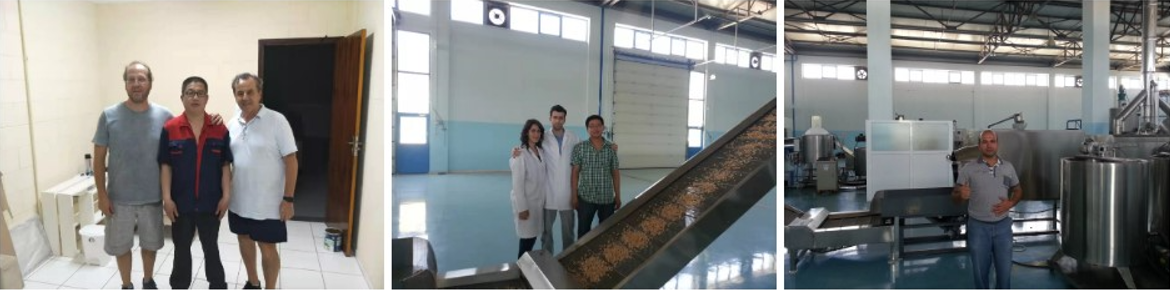

Company profile

Jinan Xilang Machine Co.,ltd is a professional Manufacturer specializing in researching and producing Extrusion machinery,Industrial microwave drying and sterilizing equipment and related ancillary equipment.The Company is located in Jinan,the spring city of Shandong. With the strong design strength,advanced producing technology and rich manufacturing experience,the company`s products get good comments from domestic and abroad customers.

Our main products include machinery and equipment for pasta system, corn flakes system, breakfast cereal system, baby food system, corn puff snacks system, fried pellets system, fortified nutrition rice system,soy nuggets system, pet food system , fish feed system , various type drying oven system, corn meal milling system etc.

Our machines have been exported to many countries of Asia, America, Africa, Europe etc. So Don't hesitate to contact us. Xilang team from pre -service to after-service will show your choice is worth it.

FAQ

1. What's the pre-sale service of your company for fried snack food processing machinery ?

Related machines’s technical parameter will be supplied to customer.

1.1 Layout can be provided in advance basing on customer’s factory size.

1.2 General formulation can be offered according to customer’s material cost,.

1.3 Machine could be customization.

1.4 Professional suggestion for Market, machines, processing , materials, packing.

1.5 Suggesting professional ship agent or helping book ship according to customer situation.

2. What's the after-sale service of your company for fried snack food processing machinery?

2.1. Allocation chart will be offered as the buyer’s request .

2.2. Professional Operation manual will be supplied after shipment.

2.3. One year warranty support, life time maintenance with cost price.

2.4. Free easy broken spare parts will be sent together with machines .

2.5. First installation supports.

2.6. Worker training supports.

3. what about spare parts after sale service for fried snack food processing machinery?

We can offer the wearing parts all the time together with changing video.

4 Are you manufacturer or trading company?

We are the manufactuer,welcome to visit us.

5 Whether you could make your brand on the products?

Yes, we could print your logo on both products and packages.

6 What is the terms of payment?

30% T/T in advance, the balance before goods leave our company.