Floating fish feed pellets extruder machine line

1.Xilang Floating fish feed pellets extruder machine line,All the machines are made by stainless steel, this line is with reasonable design and with high automation; the screws are made by alloy steel, with building block system structure and self-cleaning function.

2.Xilang Floating fish feed pellets extruder machine line can produce different shapes and sizes feed pellets for catfish, shrimps and other different aquatics. Through the Steam precuring of the fodder, it can reduce loss of nutrition and advance the protein ratio. So the fodder can be digested easily by pet animals.

1.Brieff introduction of Floating fish feed pellets extruder machine line

Xilang Floating fish feed pellets extruder machine line, adopts advanced twin-screw extrusion technology, combined with the company expanded technology research for many years of experience, in order to adapt to the demand of food, feed and other related industries and the design and manufacture of new type feed extruder, the equipment by the feeding system, extruding system, rotary cutting system, heating system, transmission system, control system.Changing the production process formula can produce a variety of specifications of fish feed products, protein content of 25%-45%.

2.The technical specification of Floating fish feed pellets extruder machine line

XL65 -III | XL70 -II | XL70 -IV | XL75 -III | XL95 -III | |

Type | dry | dry | wet | wet | wet |

Main power Consumption/Installed | 22KW/30KW | 30KW/40KW | 37KW/45KW | 55KW/75KW | 90KW/110KW |

Capacity | 120-150kg/h | 150-180kg/h | 300-400kg/h | 600-800kg/h | 1000-1200kg/h |

Size(m) | 12x4x2.2m | 13.5x4x2.2m | 16.5x4x3.2m | 18.5x4x3.2m | 21x4x3.2m |

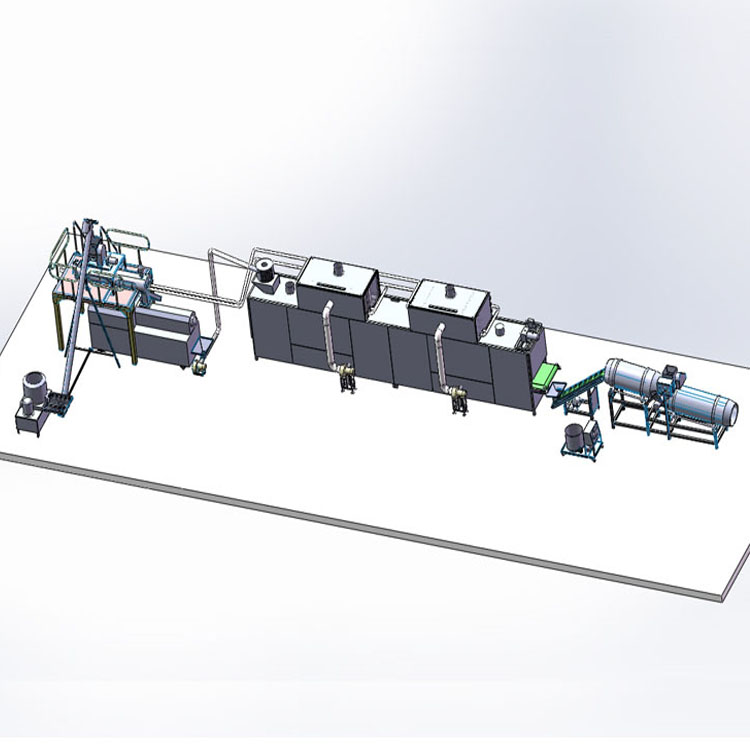

3.The Flow Chart of Floating fish feed pellets extruder machine line

Raw material---Mixing---Screw Conveying---Extruding---Air Conveying---Drying---Air Conveying---Flavoring---Cooling

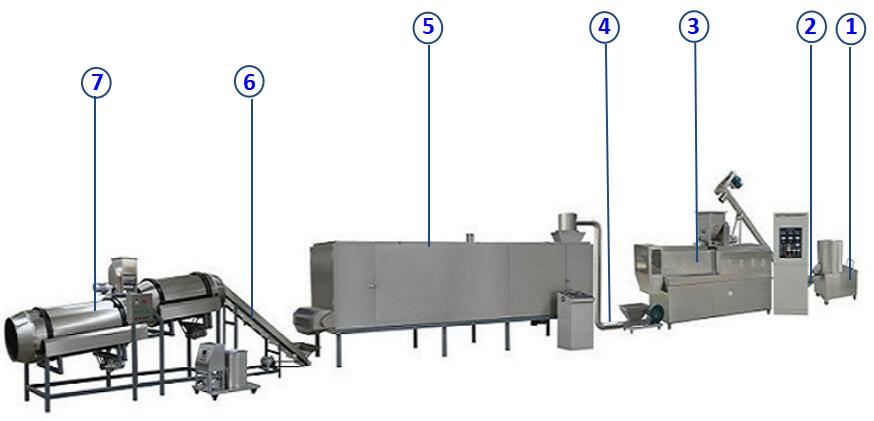

4.The composition of Floating fish feed pellets extruder machine line

NO. | Machine Name | Function |

1 | Mixer | Mix the raw material and other additives fully. |

2 | Screw conveyor | Screw turns to make the raw material convey in the sealed tube,no leaking and no pollution |

3 | Twin screw Extruder | The material is fully matured under high temperature and pressure, through the outlet mold expansion, form foods of various shapes. |

4 | Air Conveyor | conveys the food relying on the wind-force from the blower |

5 | Muti-layer Dryer | Used to bake and dry food, Net belt running speed can be controlled |

6 | Hoist | Convey the products into flavoring machine |

7 | Double rolls flavoring line | The stainless steel flavor feeder is used to spray flavor to the drum |

5.Sample photos of Floating fish feed pellets

6.Main machine features of Floating fish feed pellets extruder machine line

twin screw extruder:

1)Fully automated, with high level of operating stability; that leading to consistent product quality;

2)Highly flexible: the same processing line is able to process various types of raw materials and mix formulations, and to produce a wide range of end products;

3)Fairly well suited to product innovation, with the possibility to target easily the four basic quality attributes of food products that are taste, flavour, texture and nutrition;

4)Economical and cost-effective, due to the remarkable process-intensifying capability of extrusion processing technology.

Multii-layer dryer

1).The oven is used to dry the products continously.

2).The moister in the food which come out of the extruder is about 12-15%. With the dry of the dryer, the moister can get down below 8% and this is easy to be storage for long time.

3).For our dryer oven, there are have rock wool inside the dryer, have good leakproofness and insulation.

7.Packing and Shipping

• Use anti-rust oil to wipe the equipment puffed snacks production line

• Inside package is plastic film, outside is wooden or plywood case.

• Only plastic film nude packing with wooden pallet.

• We can supply fumigation package and certificate.

8.Projects and Certificates

9.Company Profiles