fish food making machine production line

Brand :Xilang

Product origin :Jinan

Delivery time :15days

Supply capacity :20 units per month

The fish food making machine production line has some advantages:

1.small investment, high output, small area space.

2.The whole machine is processed with stainless steel materials.

3.The production line adopts internationally advanced twin-screw extrusion technology.

1.Brief introduction of fish food making machine production line

The fish feed making machine is suitable for fish food at different growth stages. Changing molds to make fish food of different shapes.In addition,it also could produce dog food, cat food, fox food, rabbit food and so on.

2.The technical specification of fish food making machine production line

Model | XL65 -III | XL70 -II | XL70 -IV | XL75 -III | XL95 -III |

Type | dry | dry | wet | wet | wet |

Main power Consumption/Installed | 22KW/30KW | 30KW/40KW | 37KW/45KW | 55KW/75KW | 90KW/110KW |

Capacity | 120-150kg/h | 150-180kg/h | 300-400kg/h | 600-800kg/h | 1000-1200kg/h |

Size(m) | 12x4x2.2m | 13.5x4x2.2m | 16.5x4x3.2m | 18.5x4x3.2m | 21x4x3.2m |

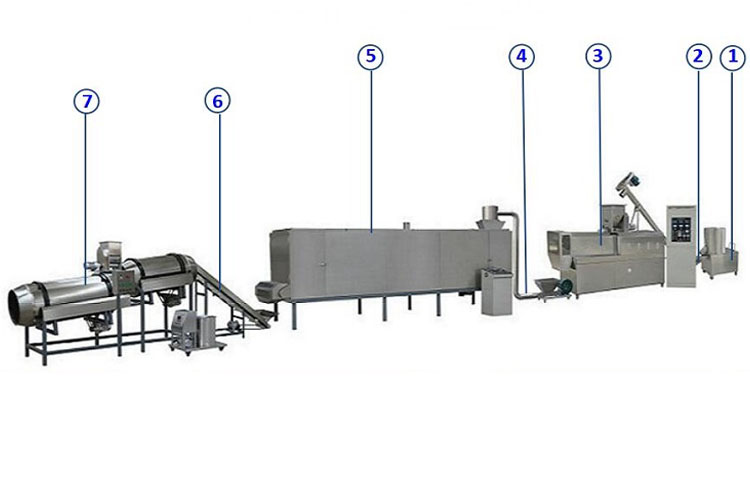

3.Flow chart of fish food making machine production line

Raw material---Mixing---Screw Conveying---Extruding---Air Conveying---Drying---Air Conveying---Flavoring---Cooling

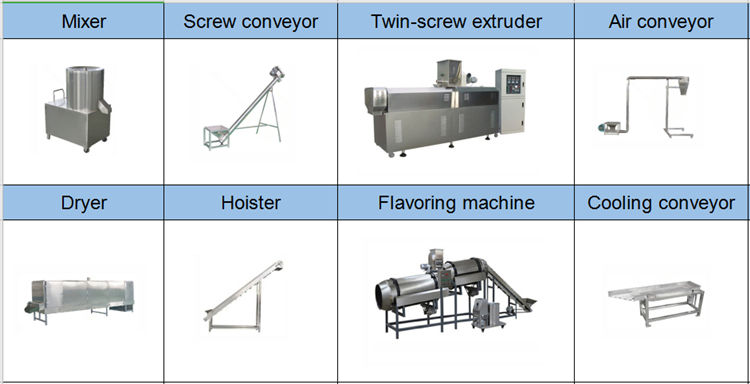

4.Equipments list of fish food making machine production line

mixer --- screw conveyor / screw feeder --- twin screw extruder --- air conveyor ---muti-layer dryer /oven --- air conveyor / elevator --- oil sprayer --- double-roller flavoring / coating machine --- cooling conveyor

5.Main machine details of fish food making machine production line

NO. | Machine Name | Technical Parameters | Function |

1 | Mixer BFJ-I | Dimension(m): 0.9×0.5×1.1 Power: 3KW | Mixing the raw material and other additives fully. |

2 | Screw conveyor LXSL-I | Dimension(m): 3.2×0.6×0.7 Power: 1.1KW | Screw turns to make the raw material convey in the sealed tube,no leaking and no pollution |

3 | Twin screw Extruder XL85- III

| Dimension(m): 2.5×0.9×1.2 Power:36KW

| Materials are extruded and cut and mixed by screw in the machine barrel. The material is fully matured under high temperature and pressure, through the outlet mold expansion, form foods of various shapes. |

4 | Air Conveyor FSJ- 1.1 | Dimension(m): 1.1×0.6×0.5 Power: 1.1KW | 1.conveys the food relying on the wind-force from the blower |

5 | Dryer KX-5-5D | Dimension(m): 5.4×1.3×1.8 Power:37.5KW

| 1.Used to bake and dry food 2.Net belt running speed can be controlled and change the food drying time in the dryer. 3.Heating adopts the electric heat tube |

6 | Cooling conveyor | Dimension(m): 5×0.5×0.9 Power:37.5KW | 1.used to cool the food with fans on the belt. 2.The total length of the conveyor is 5 meters. It is full set stainless steel. 3.The height can be adjusted based on the requirement |

6.Packing and Shipping

Packing Details:

1)Inner packing: Stretch film

2)Outside packing: Standard export wooden cases

3)The package also can be according to customer requirements.

Shipping Cost:

by ship-please tell me your delivery port; by air-please tell me your airport name; by express-please tell me your detailed address(including zip code, house number, street, city, country).