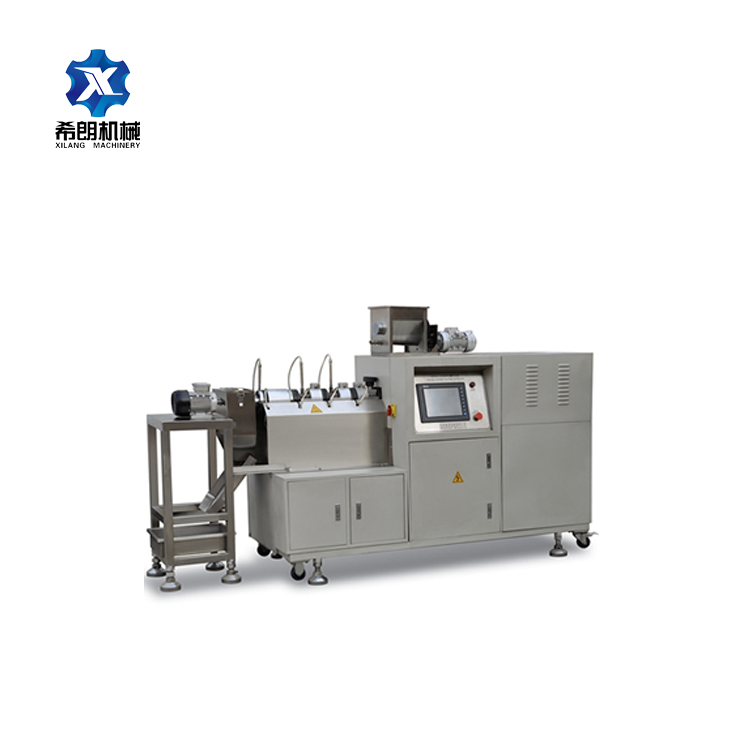

Mini Small Twin Screw Laboratory Extruder Making Machine

Brand :XI LANG

Product origin :Jinan,China

Delivery time :20days

Supply capacity : 100 sets per month

Mini Small Twin Screw Laboratory Extruder Making Machine

●Advanced technology: the expansion technology uses internationally advanced twin-screw extrusion technology;

●Small equipment investment: the price is lower than the market price;

●High output: according to different models, the output can reach up to 1000kg/h;

●Small footprint: at least 150m² can be put into production;

●High degree of automation: fully automatic production, without manual involvement;

●The whole machine is processed with stainless steel materials: to ensure sanitation and cleanliness.

Mini Small Twin Screw Laboratory Extruder Making Machine

Laboratory Extruder Making Machine Introduction

1. Lab twin-screw extruder is our company research for universities, research institutes and large and medium-sized enterprises engaged in various extrusion, extruded maturation, extruded variability study omnipotent models.

2. It is mainly used to adjust the formulation of the various corn puff snacks food, grain food, dog food, cat food, and fish feed, protein, crispy chips, sala, bugles snacks process. Research institutes and school experiments conduct research on the expansion process and data parameters.

Advantages

1. Stable performance: adopting imported frequency or electromagnetic controlling system, high automation and smooth operation.

2. Permanent working life: with special material and technology, the screw and nut involved can work continuously for 1 year under conditions of high wear and pressure.

3. The lab extruder machine is twin screw extruder which has self cleaning function.

4. The full machine is easy operation and controled by PLC systems.

Working principle of laboratory extruder making machine

Twin screw extruder is composed of feeding, extrusion, heating, rotary cutting and other parts.

Powdery raw materials through the extrusion machine, from powdery into paste, under the action of strong pressure difference, become paste material by the die hole ejection moment, the formation of loose structure of extrusion products.

The chamber of the extruder adopts multi-block type, each chamber can control the temperature independently, and the temperature is automatically controlled to ensure the taste and quality of the product.

Technical parameters of extruder

Modle | Installed Power | Power Consumption | Throughput | Dimension(mm) |

XL65-Ⅱ Processing Line | 35kw | 28kw | 120~150kg/h | 2400x1000x800 |

XL70-Ⅱ Processing Line | 45kw | 40kw | 150~200kg/h | 2600x1000x1800 |

XL75-Ⅳ Processing Line | 85kw | 70kw | 500~800kg/h | 4500x1200x1800 |

XL85-Ⅱ Processing Line | 80kw | 70kw | 300~500kg/h | 3700x1200x3000 |

XL95-Ⅱ Processing Line | 110~130kw | 90~110kw | 800~1200kg/h | 4500x1200x2600 |

XL32 Processing Line | 12kw | 8kw | 10~15kg/h | 2000x600x1500 |

The advantages of extruder

1. The screws are made by ally steel and special craft, the screw life is longer, uses building block system structure, may combine willfully.

2. The forced lubrication system, by guaranteed equipment transmission longer life.

3. Visible auto-temperature controlling system, make the temperature-controlling to be more direct-viewing, parameter to be more precise.

4. Screw speed and wide temperature range :screw speed arbitrary adjustments between 0 and 500 RPM. temperature arbitrary regulation at room temperature to 300 degrees.

Our service

Pre-sale service:

1.Related machines's technical parameter will be supplied to customer.

2.According to customer's factory size, factory layout can be provided in advance.

3. Suggesting professional ship agent or helping book ship as customer request.

After sale service:

1.Allocation chart as the buyer's request will be supplied.

2.Operation manual will be supplied after shipment.

3.One year warrantee, life time maintenance with cost price.

4.Free easy broken spare parts will be sent with container .

5.First installation can be done by engineer.

6.Training workers in customer's factory.

Packing and transportation

1.Packaging: All machines are packaged according to international standard export package.Inside is covered by plastic film, outside is wooden case.

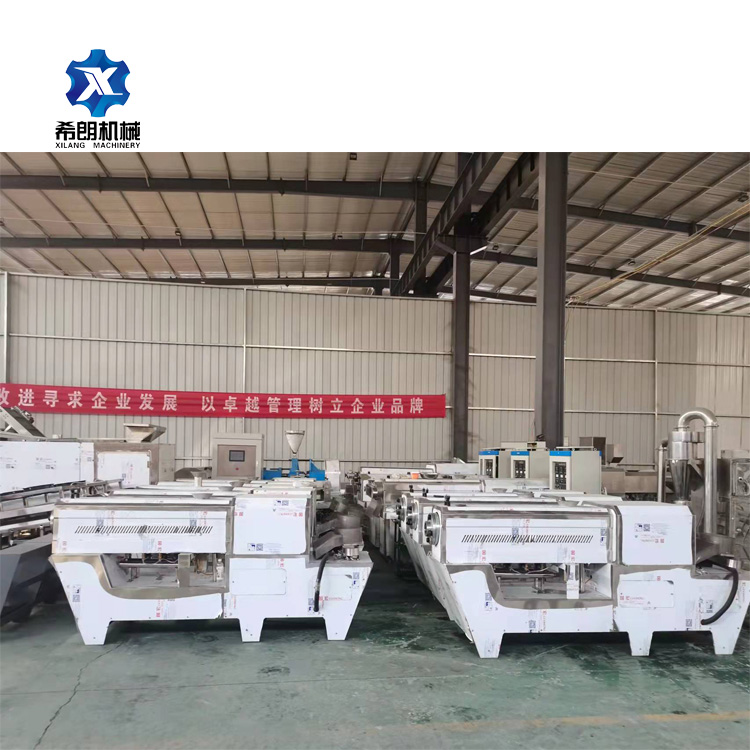

Company Profile

Jinan Xilang Machine Co.,ltd is a professional Manufacturer specializing in researching and producing Extrusion machinery,Industrial microwave drying and sterilizing equipment and related ancillary equipment.The Company is located in Jinan,the spring city of Shandong. With the strong design strength,advanced producing technology and rich manufacturing experience,the company`s products get good comments from domestic and abroad customers.

Our main products include machinery and equipment for pasta system, corn flakes system, breakfast cereal system, baby food system, corn puff snacks system, fried pellets system, fortified nutrition rice system,soy nuggets system, pet food system , fish feed system , various type drying oven system, corn meal milling system etc.

Our machines have been exported to many countries of Asia, America, Africa, Europe etc. So Don't hesitate to contact us. Xilang team from pre -service to after-service will show your choice is worth it.

FAQ

1 Are you manufacturer or trading company?

We are the manufactuer,welcome to visit us.

2 Whether you could make your brand on the products?

Yes, we could print your logo on both products and packages.

3 How about the guarantee period?

The guarantee period is 1 year after machine leave our company

4 What is the terms of payment?

30% T/T in advance, the balance before goods leave our company.

5 How long is the delivery time?