dry pet food extrder processing machine line

Brand :Xilang

Product origin :Jinan China

Delivery time :15 days

Supply capacity :20 units per month

1.Technology: Xilang dry pet food extrder processing machine line adopts advanced twin screw extrusion technology, reasonable design, high degree of automation, stable performance, easy operation.

2.Economy: Xilang dry pet food extrder processing machine line has features of small investement,high output ,small floor area etc.

1.Brief introduction of dry pet food extrder processing machine line

The dry pet food extrder processing machine line developed by Xilang Machinery Company,adopts advanced extrusion technology.The dry pet food extrder processing machine line, uses meat meal, fish meal, bone meal, bean meal, corn meal as raw materials, by adjusting the ratio of raw materials, temperature, moisture or other process parameters, This dry pet food extrder processing machine line can produce cat, dog, fish, shrimp, fox, bird and other pet feed, is the ideal choice of feed manufacturers.

2.The technical specification of pet food extrder processing machine line

Model | 65twin screw extruder line(dry type) | 70 twin screw extruder line(dry type) | 85 twin screw extruder line | 75 twin screw extruder line | 95twin screw extruder line |

Main machine power | 22kw | 30kw | 37/45 | 55/75 | 90/110 |

Drying type | gas/electric | gas/electric | gas/electric/steam | gas/electric/steam | gas/electric/steam |

Production capacity | 120-150kg/h | 150-180kg/h | 350-500kg/h | 450-600kg/h | 1000-1200kg/h |

Appearance size | 12000x4000x2200mm | 13500x4000x2200mm | 16500x4000x3200mm | 18500x4000x3200mm | 21000x4000x3200mm |

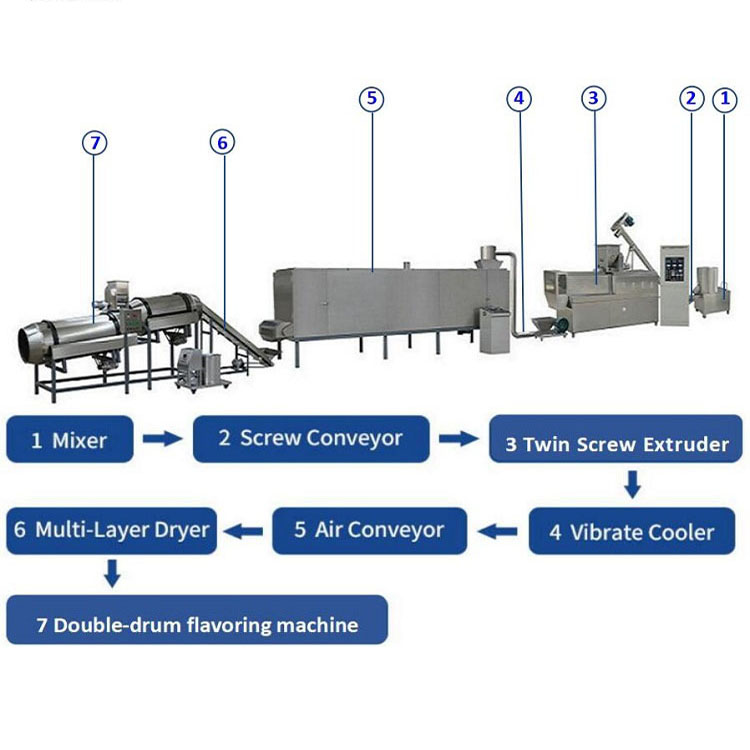

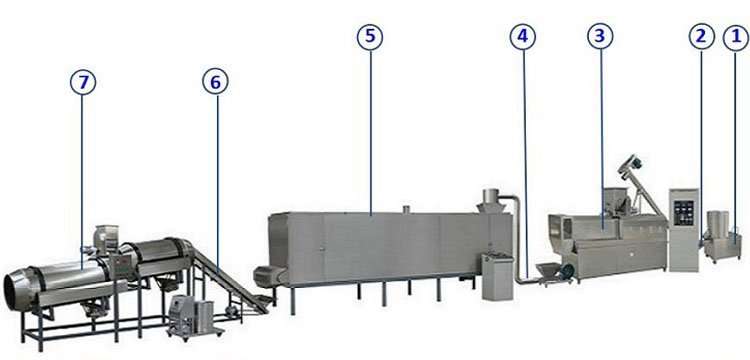

3.The flow chart of pet food extrder processing machine line

Raw material preparation→mixing→conveying→extrusion→conveying→drying→oil spraying→flavoring→cooling→screening→packaging

4.The composition of pet food extrder processing machine line

1. Mixer:add a certain proportion of water to the raw materials such as corn flour, rice flour, soybean flour, meat flour, cereal flour, additives, mix well.

2. Screw feeding machine: The motor is used for screw conveying, and the mixed raw materials are conveyed to the feeding hopper of the extruder to ensure convenient and fast feeding.

3. Twin-screw extruder: Under the conditions of high temperature and high pressure environment and screw extrusion,it could produce different feed by adjusting the production process. The specific particle size and shape can be changed.

4. Air conveyor: transporting the feed to the oven,

5. Multi-layer oven: most ovens are electric ovens. The temperature is adjusted by the control cabinet between 0-200 degrees. The inside is a stainless steel double-layer mesh bag to reduce the moisture of feed particles, promote the maturation rate and increase the shelf life.

6.Flavoring system: the oil sprayer sprays oil, phagostimulants and so on. The flavoring tube includes octagonal tube, cylinder, lifting single drum, double drum flavoring line.Spraying the grease on the feed surface according to the output and product nature configuration.Meanwhile,it spray minced meat and spices evenly.

7.Cooling and conveying: reduce the temperature of frying and feed, promote the solidification of fat, reduce the temperature of particles, and facilitate packaging.

8.Vibrating sieve: sieve out the excess sprinkled materials and particles to ensure quality while reusing of raw materials.

9.Packaging machine: manual sealing machine and automatic packaging machine can be used.

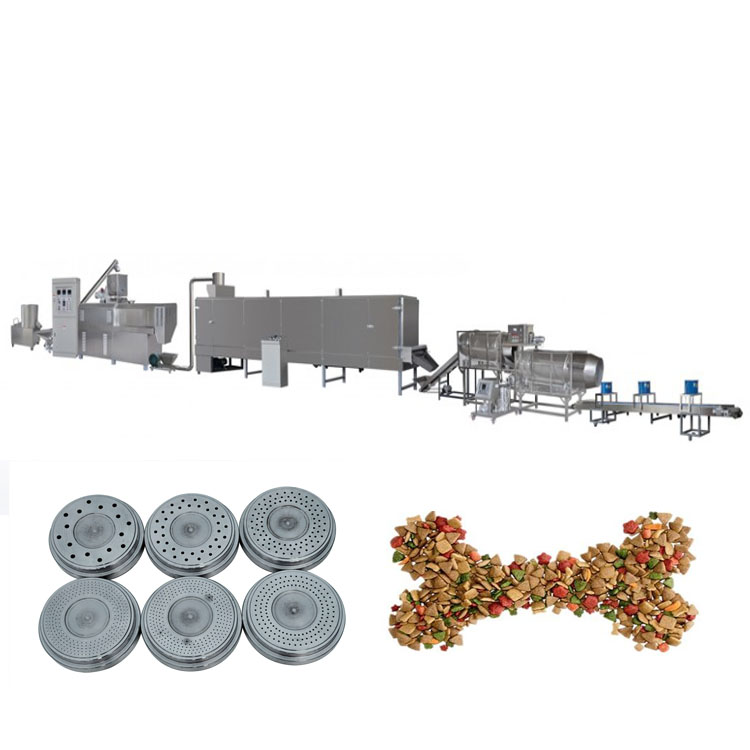

5.Sample pictures of dry pet food

6.The main extruder features of pet food extrder procmessing machine line

1.The screw material: Alloy steel (38CrMoAL) by nitriding process. High strength and wear-resting. With good self-cleaning ability, it's unnecessary to remove the barrel and screws for cleaning.

2. SIMENS (China) Motor.

3. It adopts speed-adjusted converter on feeding system, extrusion system and cutting system. Food grade stainless steel twin screw feeding device guarantees stable materials feeding in the whole food process.

4. Adopted the Delta inverters, ensure the extruder better running.

5. The gearbox has automatic lubrication function, which prolong service life of gears.

6. Cutting knife is fixed in the die head seat, rotary cutting driven by motor.

7.Packing and Deliverying

Packaging:

daub coal oil on the surface to protect the machine from moisture, Then cover with plastic film. Finally pack them with wooden case.

Transportation cost:

by ship-please tell me your delivery port; by air-please tell me your airport name; by express-please tell me your detailed address(including zip code, house number, street, city, country).

8.Certificates and Projects