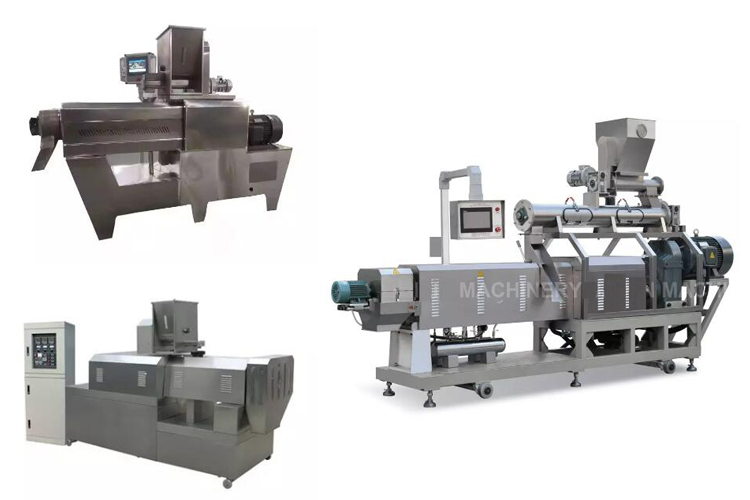

dog and cat food making machine line

Brand :Xilang

Product origin :Jinan China

Delivery time :15days

Supply capacity :20 units per month

1.dog and cat food making machine line adopts twin screw extrusion technology.

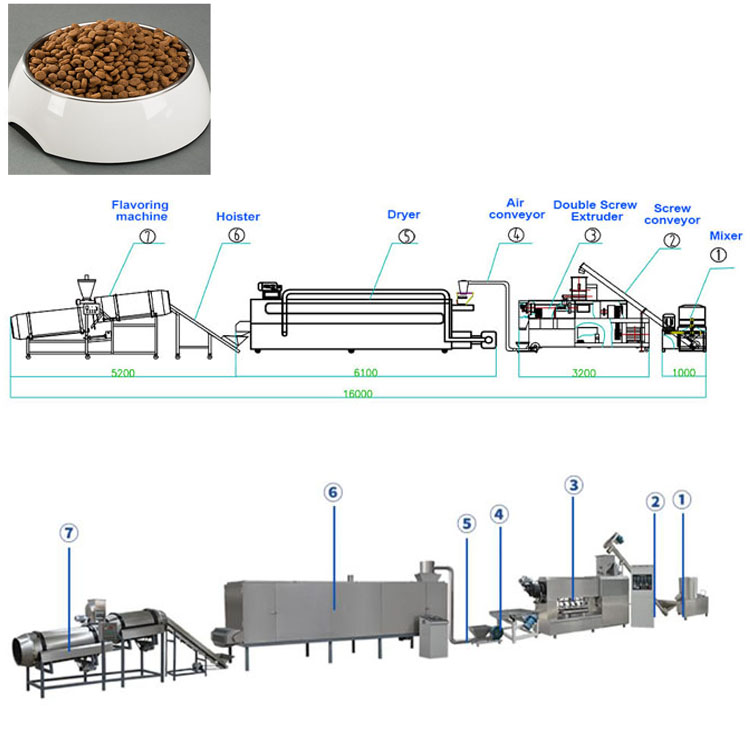

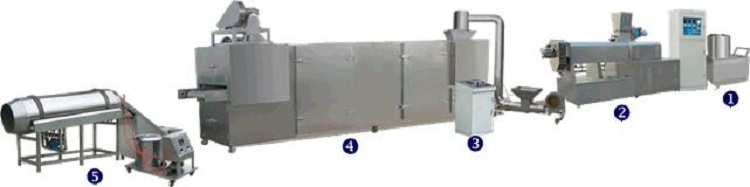

2.The whole dog and cat food making machine line is made up of Mixing system, Extrusion system, Drying system and Flavoring system.

3.The dog and cat food making machine line is multi-function machine line, which not only can produce various animal feeds,Also can be used for producing both floating and sinking fish feed .

1.Brief introduction of dog and cat food making machine line

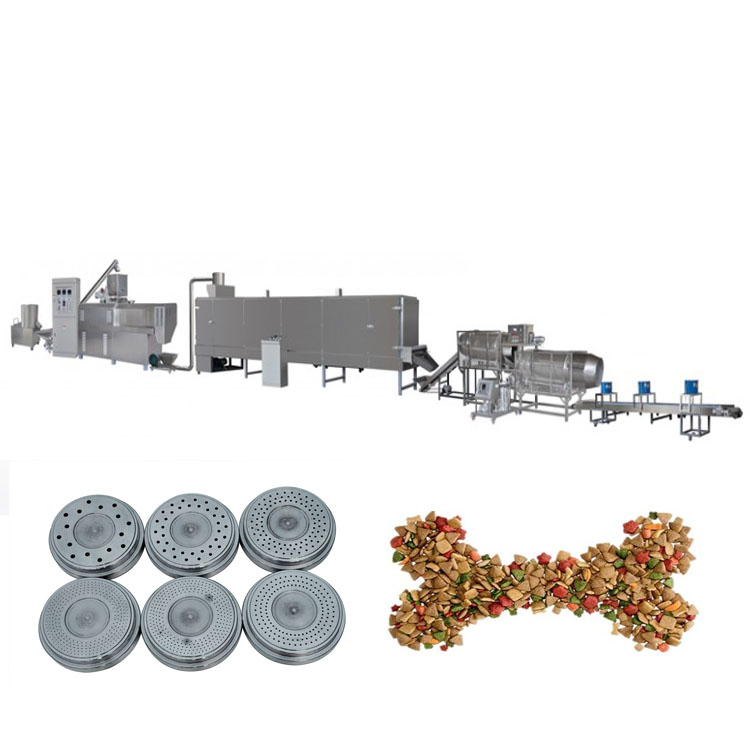

The Xilang dog and cat food making machine line uses meat meal, fish meal, corn powder, soya meal and other grains powder as main materials to produce pet food, such as dog, cat, fish, bird food etc.

By changing formula and molds,this line can produce different shapes and sizes feed pellets for various animals at different growth stages.

2.The technical specification of dog and cat food making machine line

Model | 65twin screw extruder line(dry type) | 70 twin screw extruder line(dry type) | 85 twin screw extruder line | 75 twin screw extruder line | 95twin screw extruder line |

Main machine power | 22kw | 30kw | 37/45 | 55/75 | 90/110 |

Drying type | gas/electric | gas/electric | gas/electric/steam | gas/electric/steam | gas/electric/steam |

Production capacity | 120-150kg/h | 150-180kg/h | 350-500kg/h | 450-600kg/h | 1000-1200kg/h |

Appearance size | 12000x4000x2200mm | 13500x4000x2200mm | 16500x4000x3200mm | 18500x4000x3200mm | 21000x4000x3200mm |

3.The flow chart of dog and cat food making machine line

grinding→mixing→extruding→drying→flavoring→cooling→packing

4.The machine details of dog and cat food making machine line

| Name | Mixer |

Capacity | 40kg/batch,3-4minutes/batch | |

Usage | Mixing raw material with water or other additives. | |

Installed/ Actual Powder | 3kw/2kw | |

Size | 1030*720*1350mm | |

Motor | Chinese famous brand | |

Material | The mixer contacts to material adopts stainless steel material. |

| Name | Twin screw extruder |

Usage | extrude the raw materials and make them to the required shape and size of the snack food pellets by mould | |

Capacity | 100-150kg/h | |

Installed/ Actual Powder | 10kw/8kw | |

Size | 1500×600×1600mm | |

Material | Stainless steel Screw:38CrMnAl | |

Working | It consists of feeding system, extruding system, cutting system, heating system; main motor and controlling system. |

| Name | Multi-layer dryer |

Usage | Low temperature drying to remove moisture. | |

Capacity | 150kg/h | |

Installed/ Actual Powder | 27kw/22kw | |

Size | 5000×1300×2200mm | |

Material | Stainless steel |

5.Main Extruder Features of dog and cat food making machine line

1)The main extruder of dog and cat food making machine line is made up of feeding system, heating system, extrusion system and cutting system. The main system of automatic full line snack puff make machine adopts frequency speed with high automation controlling.

2)The screws of Twin Screw Extruder are made of the special alloy steel (38CrMoAl)which has the advantage of durable usage, high pressure,and longer life.

3)The forced lubrication system of dog and cat food making machine line can guarantee the equipment transmission life longer.

4)Auto-temperature control system and self-cleaning of dog and cat food making machine line make machine makes it more convenient.

5)dog and cat food making machine line has the widest range of applications and can produce different products with different equipment and models.

6.Packing and Shipping

Packaging:

daub coal oil on the surface to protect the machine from moisture, Then cover with plastic film. Finally pack them with wooden case.

Transportation cost:

by ship-please tell me your delivery port; by air-please tell me your airport name; by express-please tell me your detailed address(including zip code, house number, street, city, country).

7.Certificates and Projects

8.Company Profile