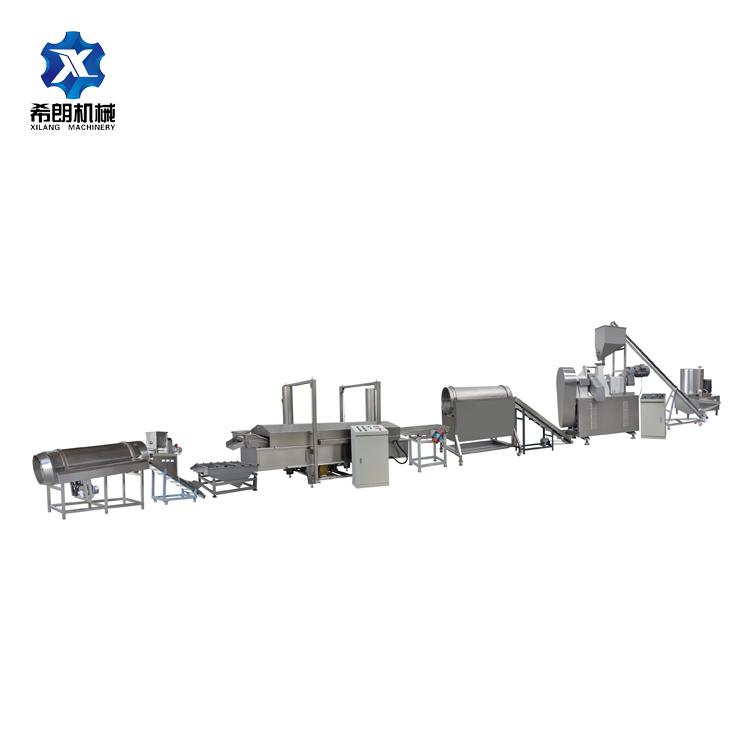

Fried cheetos corn curls production line

Brand :XI LANG

Product origin :Jinan,China

Delivery time :20days

Supply capacity : 100 sets per month

1. Jinan Xilang Fried cheetos Production Line, from raw material preparation, extrusion, molding, cutting, baking, spraying, seasoning to finished products completed in one time, high degree of automation. Easy to operate.

2. The production line has many models, flexible configuration, wide range of raw materials, various products, simple operation and so on.

3. Chetoos has a crisp taste, easy to digest, unique fragrance, convenient to carry, and is the ideal leisure food for consumers

1.Product Description of Fried cheetos Production Line

1.1 brief introduction

Kurkure/Cheetos are special extruded snacks, very crunchy and great in taste. The main raw material is corn grits which is mixed with water evenly by the flour mixer, squeezed and twisted by the extruder to form the iregular curls shape, and then cut into different length, at last fried or baked and flavored. Such snacks with rich taste are always the customer's favor.

1.2. Raw materials of Fried cheetos Production Line

Adopts corn grits as raw materials meanwhile mixing with water and oil.

1.3. Products produced by Fried cheetos Production Line

This line can be used to produce cheetos, kurkure, and nik naks

2.Technical parameter of Fried cheetos Production Line

Item | Capacity | Install power | Dimension |

XL-II baking cheetos line | 150~200 kg/h | 57kw | 24000*4500*2800 mm |

XL-II frying cheetos line | 150~200 kg/h | 48 kw | 22000*2300*2800 mm |

3.Flow Chart of Fried cheetos Production Line

The Kukure Cheetos Puffs Crunchy Processing Line:

Mixing system---Extrusion system----Baking system / Frying System ---Flavoring system---Packing system

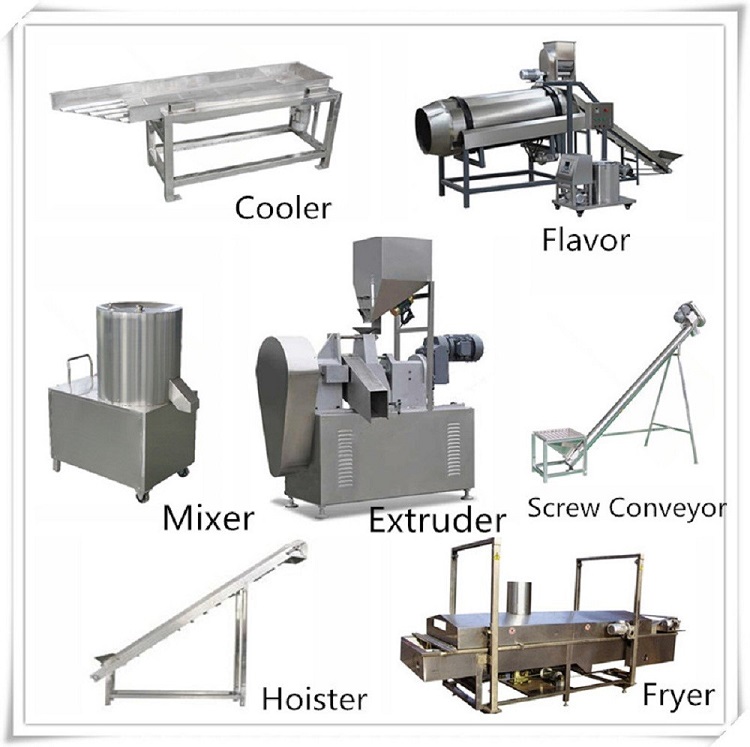

Equipments list of kurkure niknaks cheetos production line

Baked Type:

① Mixing machine →② screw conveyor →③ rotary head extruder →④ hoist →⑤ muti-layer oven →⑥ flavoring machine

Fried type:

① mixing machine →② screw conveyor →③ rotary head extruder →④ hoist →⑤ separate drum / cylinder →⑥ vibration screen / feeder →⑦ continuous frying machine →⑧ Vibration deoiling machine →⑨ seasoning line

Items of kurkure niknaks cheetos production line

No. | Description | Function |

1 | Mixer | Mix the materials with water or other liquid. |

2 | Screw Conveyor | Convey the materials into twin screw extruder. |

3 | Rotary head extruder | Extrude the raw materials and make them to the required shape and size of kurkure cheetos. |

4 | Hoist | Convey the products to next step machine. |

5 | Multi-layer oven | Bake and dry the extruded products. |

6 | Rotary drum dryer | Separate and dry the extruded products. |

7. | Vibrating feeder | Prevent particles bonding and Cool temperature down. |

8 | Continuous fryer | Frying and deoiling |

9 | Flavoring | Spray flavor materials on surface |

10 | Packing machine | Pack the snack food with required weight |

4.Rotary head extruder features

1)American technology,made in China

2)Gravity feed hopper with vibrator for metered flow of raw materials.

3)Speed control of the feed screw via the inverter(included)

4)Manual head gap is controlled by mechanical ratchet.

5)Table slides back via hand crank for easy adjustment of feed screw and easy access to extruder components.

5.Sample Photos

6.Packing and Shipping

1)Inner packing: Stretch film

2)Outside packing: Standard export wooden cases

3)The package also can be according to customer requirements.

3)If you want to know the transportation cost:

by ship-please tell me your delivery port; by air-please tell me your airport name;

by express-please tell me your detailed address(including zip code, house number, street, city, country).

7.Company Profile:

Jinan Xilang Machine Co.,ltd is a professional Manufacturer specializing in researching and producing Extrusion machinery,Industrial microwave drying and sterilizing equipment and related ancillary equipment.The Company is located in Jinan,the spring city of Shandong. With the strong design strength,advanced producing technology and rich manufacturing experience,the company`s products get good comments from domestic and abroad customers.

Our main products include machinery and equipment for pasta system, corn flakes system, breakfast cereal system, baby food system, corn puff snacks system, fried pellets system, fortified nutrition rice system,soy nuggets system, pet food system , fish feed system , various type drying oven system, corn meal milling system etc.

Our machines have been exported to many countries of Asia, America, Africa, Europe etc. So Don't hesitate to contact us. Xilang team from pre -service to after-service will show your choice is worth it.

8.FAQ

Q1: Are you a trade company or a manufacturer?

A1:We are a manufacturer,we have own factory and R&D department.

SGS has certified our company on site.welcome to visit our factory and check the machines.

Q2: How long is your delivery time?

A2: Generally it is 5-10 days if the goods are in stock. or it is 20-35 days if the goods are not in stock, we could discuss before contract.

Q3: Could you supply all the parameters about the machines?

A3: Yes, we will supply all the parameters, price, layout drawing, factory design etc.

Q4. Can you provide food or feed formula?

A4: We can provide basic formula for produce the food etc.

And help customer to produce new products according to customer’s formula.

Q5: What is your terms of payment ?

A5: 30% T/T in advance ,70% balance before shippment after inspection.

Q6: How about the after-service?

A6: We will send 1 engineer to the buyer's factory for 7-14 days period installation and training to the operators.