Pet Dog Cat Food Extruder Production Line

Brand :XI LANG

Product origin :Jinan,China

Delivery time :20days

Supply capacity : 100 sets per month

1.The twin screw extruder can efficiently mix various ingredients such as cereal, soybean meal, animal meal, fresh meat, fat, nutrients, protein, vitamins, starch and wet fish residue. Can produce more consistent products and more diverse products;

2.Feeding, rotary cutting, main drive motor adopts frequency conversion speed regulation, stable operation, strong power, energy saving and low noise;

3.The new twin screw extruder with large torque and high speed can bring greater economic benefits where large extruder is needed in the past.

1.Product Introduction of Pet Dog Cat Food Extruder Making Machine Production Line:

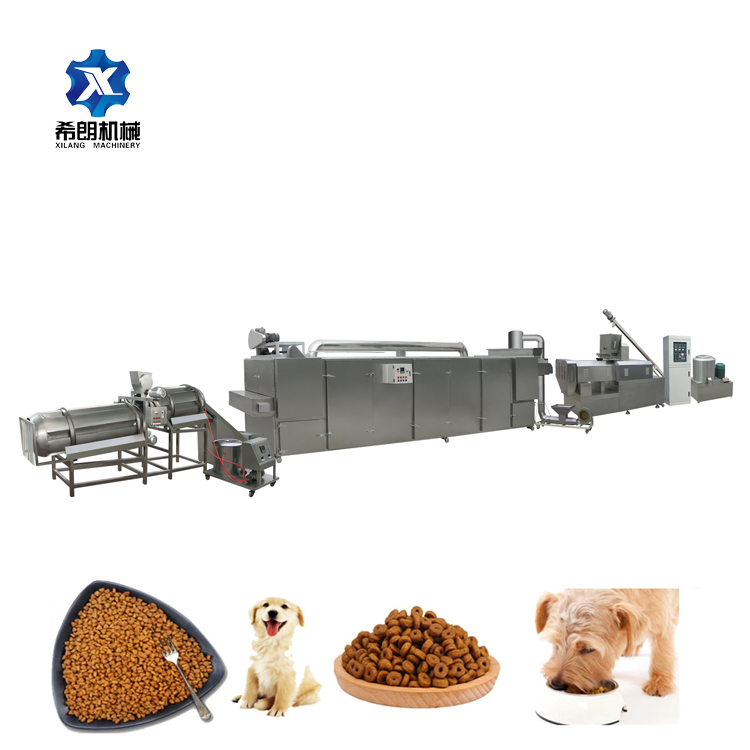

Pet Dog Cat Food Extruder Making Machine Production Line is Widely used in the production of various of pet foods like dog food, cat food,fish feed and so on. It is and ideal choice for manufactures with rigid requirements. The whole machine is made of stainless steel which can ensure hygiene and cleanliness. The technology uses internationally advanced twin screw extrusion technology.

Raw Materials of pet food extruder making machine:

Meat Meal, Fish Meal, Corn Powder, Soya Meal and Other Grain Powder

Machines Materials of pet food extruder making machine :

All the machines are made by food grade stainless steel

Products produced by pet food extruder making machine:

The line is multi-functional line ,it suitable for producing vairous type products like Pet Food, Like Dog, Cat, Fish, Bird Food etc. with Different Shapes and Tastes by

Changing the Dies and Formulations.

2.Technical parameter of Pet Dog Cat Food Extruder Making Machine Production Line

Model | 65twin screw extruder line (dry type) | 70 twin screw extruder line (dry type) | 70 twin screw extruder line (wet type) | 75 twin screw extruder line (dry type) | 95twin screw extruder line (wet type) |

Main machine power | 22kw | 30kw | 37/45 | 55/75 | 90/110 |

Drying type | gas/electric | gas/electric | gas/electric/steam | gas/electric/steam | gas/electric/steam |

Production capacity | 120-150kg/h | 150-180kg/h | 300-400kg/h | 600-800kg/h | 1000-1200kg/h |

Appearance size(mm) | 12000x4000x2200 | 13500x4000x2200 | 16500x4000x3200 | 18500x4000x3200 | 21000x4000x3200 |

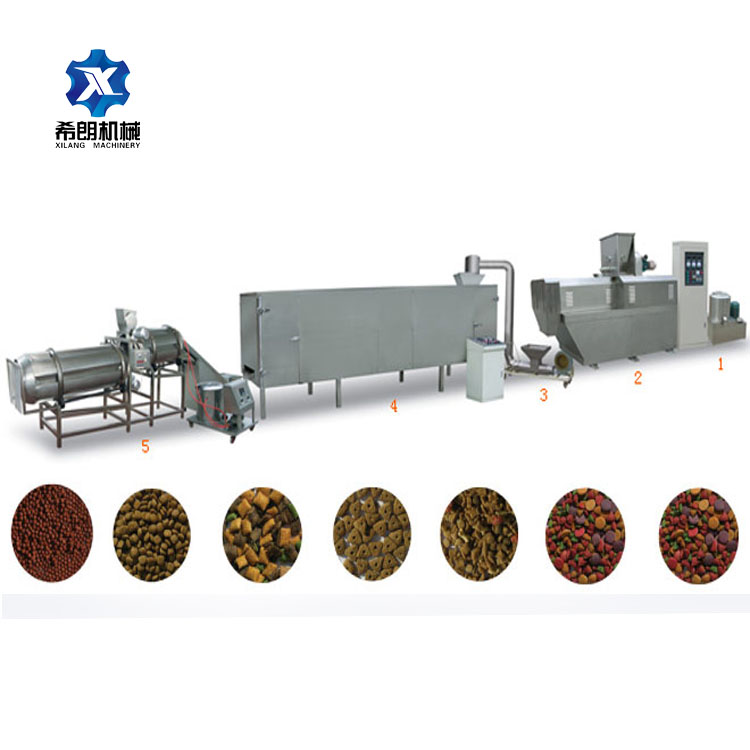

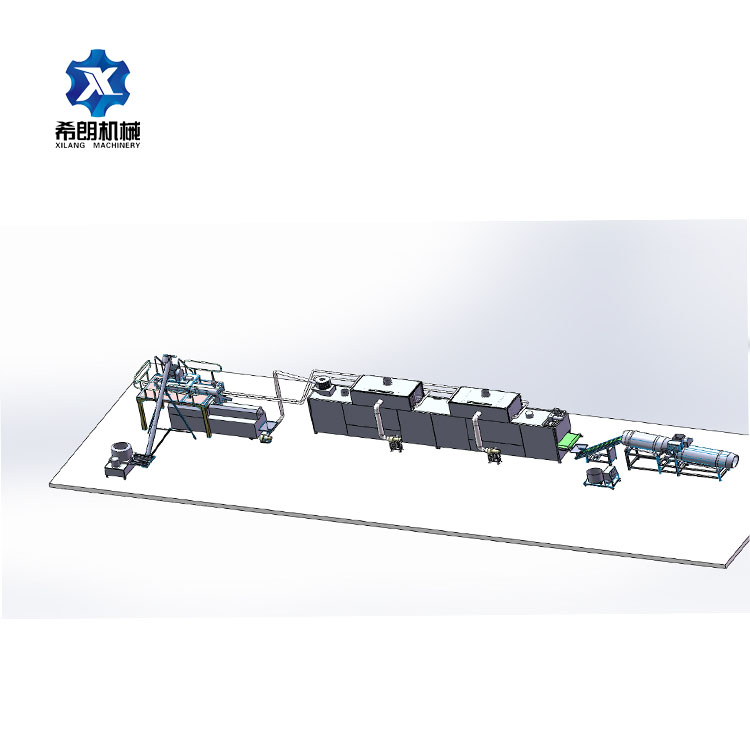

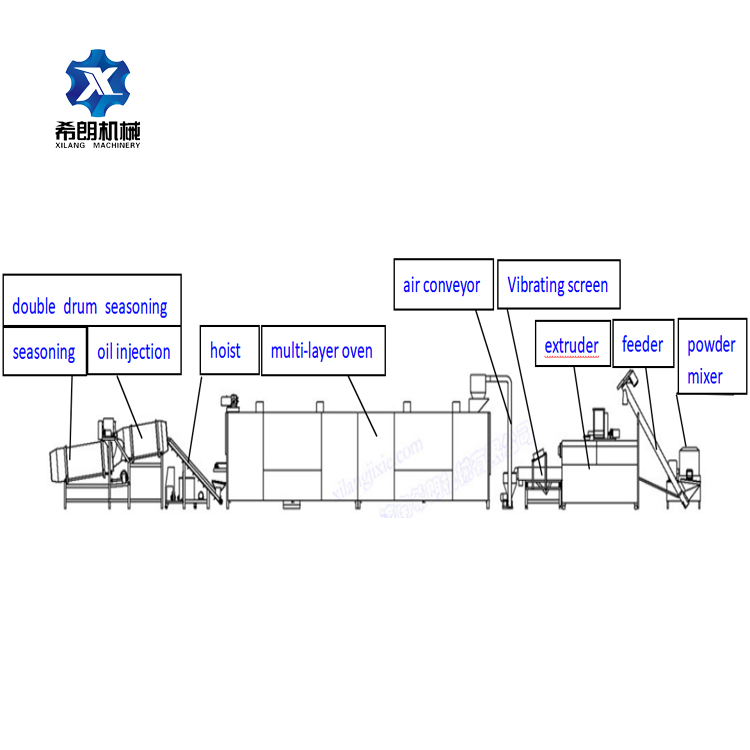

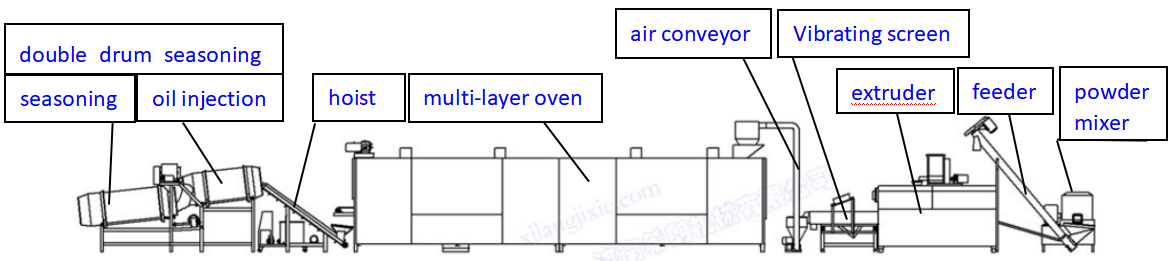

3.Process flow and equipment configuration of pet feed making machine

powder mixer →screw feeder → twin screw extruder → air conveyor → multi-layer oven → hoister → Oil sprayer → flavoring machine → cooler-storage bin-packaging

4.Process composition of pet food production line:

4.1. Flour mixing machine: Add a certain proportion of water to the raw materials such as corn flour, rice flour, soybean flour, meat flour, cereal flour, additives, etc., and mix well.

4.2. screw conveyor: The motor is used for screw conveying, and the mixed raw materials are conveyed to the feeding hopper of the extruder to ensure convenient and fast feeding.

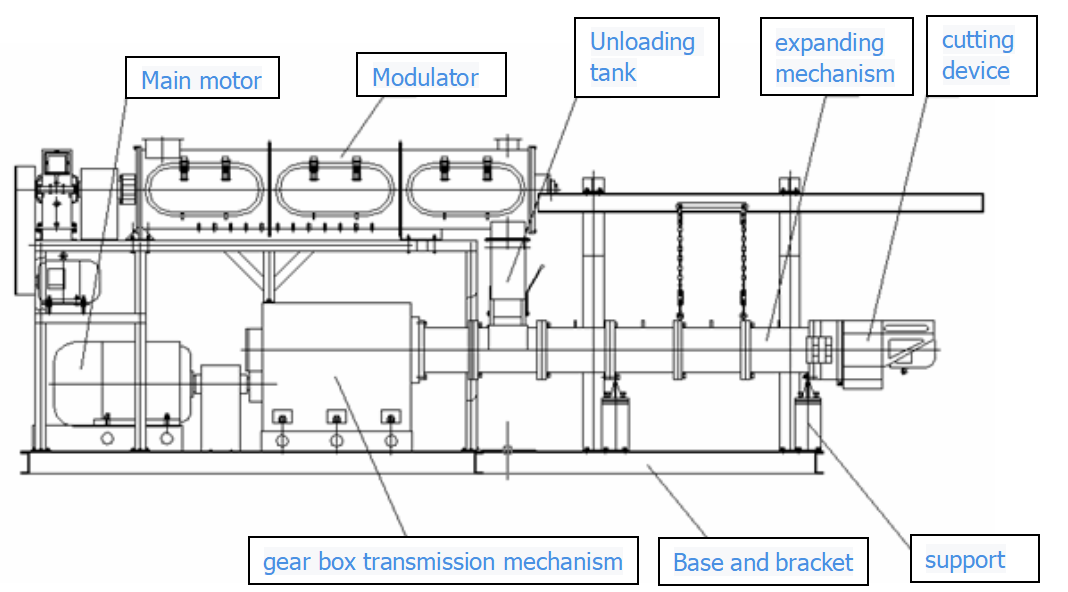

4.3. Twin-screw extruder: Under the conditions of high temperature and high pressure environment and screw extrusion, the die can be changed by adjusting the different feeds of the production department of the process, the specific particle size and shape.

4.4. Conveyor: send the feed to the oven,

4.5. Multi-layer oven: The oven is mostly electric oven. The temperature is adjusted between 0-200 degrees through the control cabinet. The inside is a stainless steel double-layer mesh bag, which reduces the moisture of feed particles, promotes the maturation rate and increases the shelf life.

4.6. Seasoning line: the oil sprayer sprays oil, attractant, etc., we recommend the complete set of pet feed equipment in Jinan, related to pet feed production line. The seasoning tube includes octagonal tube, cylinder, lifting single drum, double drum seasoning line, according to the output , Product nature configuration, spray grease on the surface of the feed, and spray minced meat and spices at the same time to spread evenly.

4.7. Cooling and conveying: reduce the temperature of frying and feed, promote the solidification of fat, and reduce the temperature of pellets. Check Jinan pet feed equipment, pet food and pet feed machinery related to easy packaging.

5.The main features of Xilang Machinery twin-screw extruder:

5.1. Feeding, rotary cutting, and main drive adopt frequency conversion speed regulation system, which has strong power, stable operation and energy saving.

5.2. The screw is made of alloy material through a special process and has a long service life. It has a wide range of applicable raw materials and more diverse products.

5.3. The automatic lubrication system reduces the mechanical energy consumption and prolongs the service life.

5.4. The feeding system adopts double spiral forced feeding, and the feeding is uniform and wide.

5.5. Linear bearing tool adjustment system, adjust the tool accurately and quickly.

5.6. The twin screw has a self-cleaning function, and the use of equipment is more reasonable and convenient.

5.7. Update various equipment technology and equipment configuration is that the output of the twin-screw extruder is larger.

5.8. Different screws and length-to-diameter ratios can meet different production processes.

5.9. Visual automatic temperature control system to make temperature control more intuitive and more parameters.

5.10. The overall equipment configuration using this extruder is more intuitive and easier to maintain.

6. Pet food Sample picture

7.Company Profile:

Jinan Xilang Machine Co.,ltd is a professional Manufacturer specializing in researching and producing Extrusion machinery,Industrial microwave drying and sterilizing equipment and related ancillary equipment.The Company is located in Jinan,the spring city of Shandong. With the strong design strength,advanced producing technology and rich manufacturing experience,the company`s products get good comments from domestic and abroad customers.

Our main products include machinery and equipment for pasta system, corn flakes system, breakfast cereal system, baby food system, corn puff snacks system, fried pellets system, fortified nutrition rice system,soy nuggets system, pet food system , fish feed system , various type drying oven system, corn meal milling system etc.

Our machines have been exported to many countries of Asia, America, Africa, Europe etc. So Don't hesitate to contact us. Xilang team from pre -service to after-service will show your choice is worth it.

Our services

1. OEM & ODM

2. One year guarantee and life-time maintenance service.

3. Consultation service before, during, and after sales.

4. Project planning and design services.

5. Debugging of machines until all are functional.

6. Training the customers how to operate and maintain the machines correctly

Packing and shipping for pet food machine