Nutritional Baby Food Powder Making Machine Processing Line

Brand :XI LANG

Product origin :Jinan,Shandong

Delivery time :20days

Supply capacity : 100 sets per month

1, technical aspects: puffing nutrition powder production line adopts twin screw extrusion technology to replace the traditional cooking rice flour production of new technology, microwave curing to solve the problem of oil, fiber high products difficult to puffing, a high temperature drying sterilization curing, multi-purpose machine, cost saving.

2, equipment: solid beverage - nutrition powder production line full set of equipment selection of food grade stainless steel production, set mixing, puking, curing, sterilization, crushing, packaging in one, high degree of automation, strong stability, simple operation, energy saving and low noise.

3. Products: Puffing raw materials can be single raw materials, or a variety of mixed raw materials. Changing raw materials and auxiliary equipment can change the product to produce different flavor of nutritional powder.

Nutritional Baby Food Powder Making Machine Processing Line

The nutrition powder extrusion line use corn, rice, millet, wheat, oats, yams, konjac, red beans, barley and other grains as raw materials (can be a single raw material, can also be a variety of mixed raw materials). The instant powder was prepared by gelatinizing starch and maturing protein through extrusion process.

Raw material of nutrition powder processing line: corn, rice, beans and all of grains.

The technical specification of nutrition powder production line

Model | XL65-II | XL70-II | XL75-I | XL85-II | XL95-I |

Main machine power kw | 22 | 30/37/45 | 55/75/90 | 110/132 | 132/160 |

Actual consumption power kw | 20 | 25/30/35 | 40/70/85 | 105/128 | 128/155 |

Production capacity kg/h | 120-150 | 150-220 | 300-500 | 600-800 | 800-1200 |

Appearance size mm | 2600x850x1800 | 2900x850x1800 | 4200x1000x2300 | 5600x1100x2500 | 6500x1200x2800 |

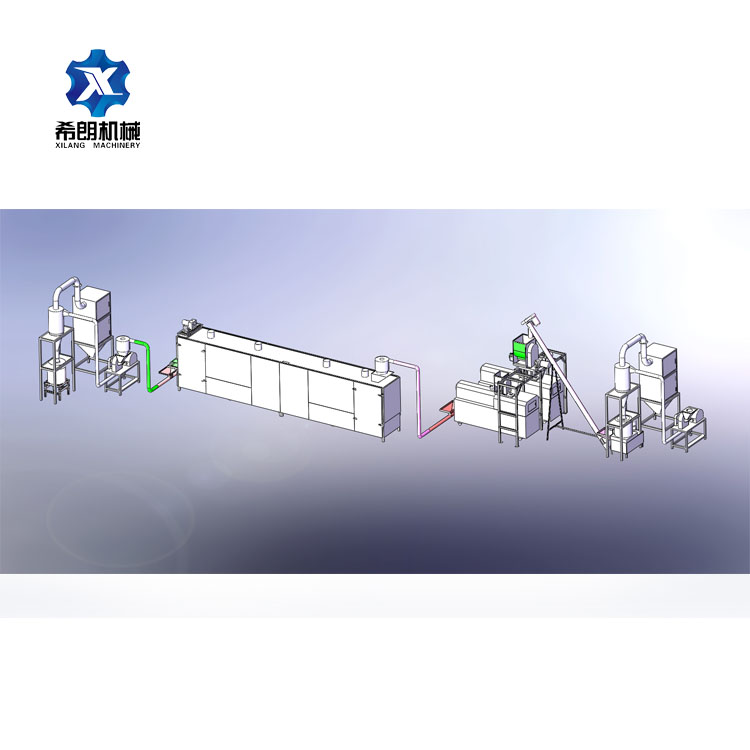

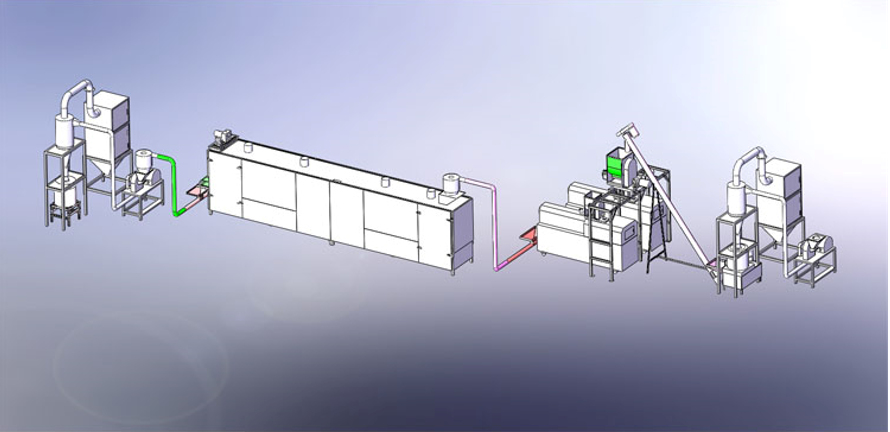

Process flow of nutrition rice making machine:

Raw material configuration - raw material mixing - extrusion - puffing - drying - crushing - packaging

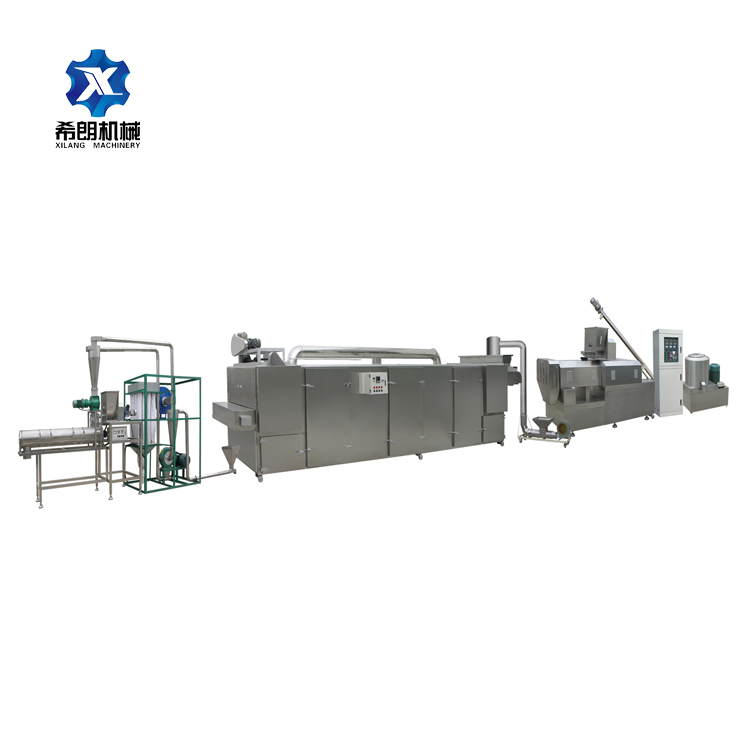

Equipment composition:

Mixing machine → feeding machine → puffing machine → air feeder → multi-layer oven → crusher → (packaging machine)

Sample picture

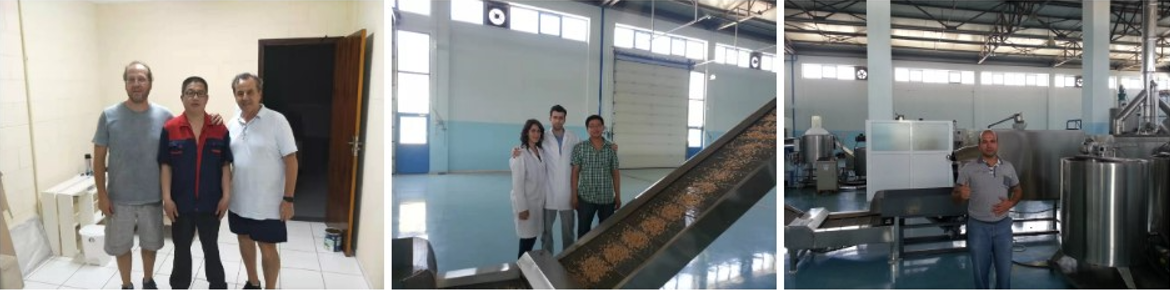

Customer & Exhibition

Packing & Delivery

1.Packaging: All nutrition powder making machines are packaged according to international standard export package.Inside is covered by plastic film, outside is wooden case.

COMPANY PROFILE

Jinan Xilang Machine Co.,ltd is a professional Manufacturer specializing in researching and producing Extrusion machinery,Industrial microwave drying and sterilizing equipment and related ancillary equipment.The Company is located in Jinan,the spring city of Shandong. With the strong design strength,advanced producing technology and rich manufacturing experience,the company`s products get good comments from domestic and abroad customers.

Our main products include machinery and equipment for pasta system, corn flakes system, breakfast cereal system, baby food system, corn puff snacks system, fried pellets system, fortified nutrition rice system,soy nuggets system, pet food system , fish feed system , various type drying oven system, corn meal milling system etc.

Our machines have been exported to many countries of Asia, America, Africa, Europe etc. So Don't hesitate to contact us. Xilang team from pre -service to after-service will show your choice is worth it.

Our Services

a. ) Consultation service before, during, and after sales;

b .) Project planning and design service;

c.) Debugging of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

e.) Training of equipment maintenance and operating personally;

f.) Provide 1 year complete warranty and life-time maintenance service.

FAQ

1. What's the pre-sale service of your company for nutrition powder making machine ?

Related machines’s technical parameter will be supplied to customer.

1.1 Layout can be provided in advance basing on customer’s factory size.

1.2 General formulation can be offered according to customer’s material cost,.

1.3 Machine could be customization.

1.4 Professional suggestion for Market, machines, processing , materials, packing.

1.5 Suggesting professional ship agent or helping book ship according to customer situation.

2. What's the after-sale service of your company for nutrition powder making machine ?

2.1. Allocation chart will be offered as the buyer’s request .

2.2. Professional Operation manual will be supplied after shipment.

2.3. One year warranty support, life time maintenance with cost price.

2.4. Free easy broken spare parts will be sent together with machines .

2.5. First installation supports.

2.6. Worker training supports.

3. what about spare parts after sale service for nutrition powder making machine?

We can offer the wearing parts all the time together with changing video.

We are the manufactuer,welcome to visit us.

Yes, we could print your logo on both products and packages.