Self-heating Nutrition Instant Rice machine

Brand :Xilang

Product origin :Jinan

Delivery time :20days

Supply capacity :100sets/months

1.Advanced technology: the expansion technology uses internationally advanced twin-screw extrusion technology;

2.Small equipment investment high output: the price is lower than the market price;

according to different models, the output can reach up to 900kg/h;

3.High degree of automation: fully automatic production, without manual involvement;

1.Product Discription

Brief Introduction to the Automatic Self-heating Instant Rice Production Line

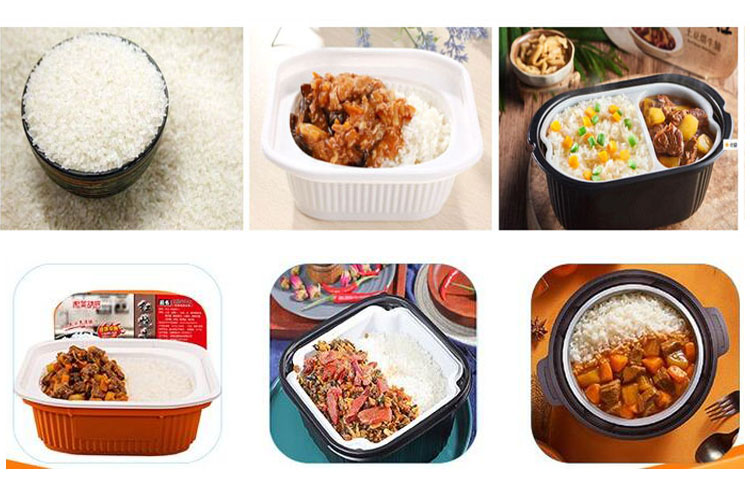

This production line can use rice, millet, black rice, buckwheat, corn and other grain as raw material, add a variety of vitamins, proteins and minerals processing, after extruding, curing and forming in extrusion machine to generate a new strengthening nutrition rice, taste soft hard moderate, after bubble water heating shape remains unchanged, both nutrition and adjusting to the fast pace of modern life.

Raw Materials:

adopts broken rice rice, corn, millet, wheat, oats, buckwheat, bean, starch as main ingredient, and some other vitamin and mineral as part of ingredient.

Instant Rice Products:

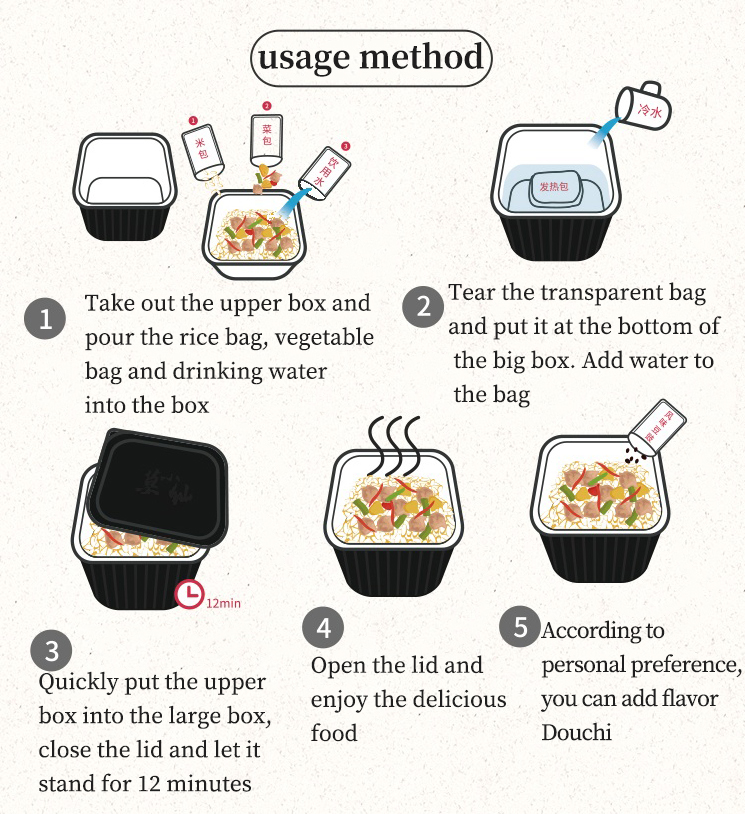

When eating the self-heating rice, there is no need for boiling water or thermal electricity. Tear the outer package and pour the purified water bag inside onto the heating bag. The water and the heating bag will automatically mix and heat up, and the rice and dishes will be steamed for 8-10 minutes.

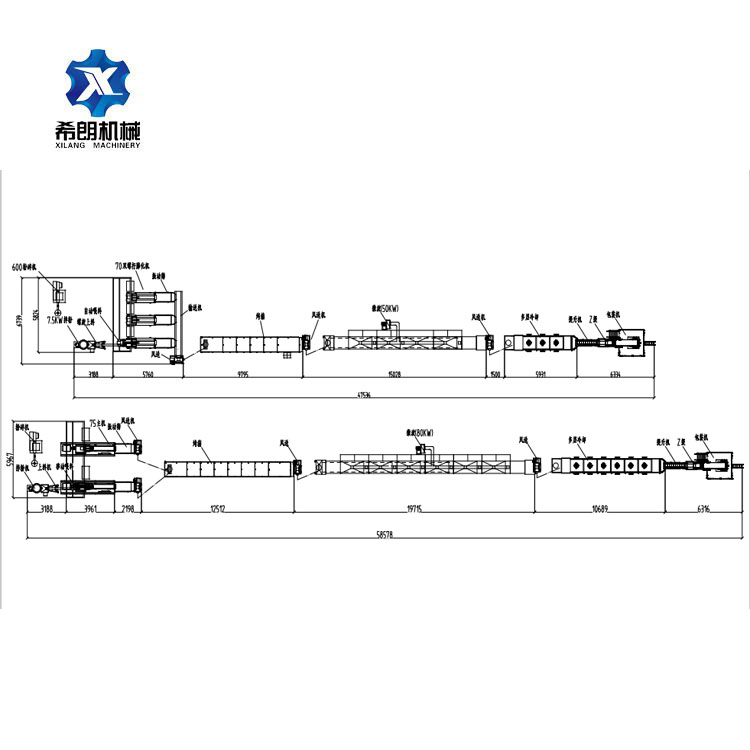

2.Technical Specifications for Instant Rice Processing Line

| Model | XL65-III nutritional rice processing line | XL70-II nutritional rice processing line | XL75-II nutritional rice processing line |

| Installed power | 54kw | 60kw | 135.5kw |

| Actual consumption power | 35kw | 40kw | 105kw |

| Production capacity | 120-150kg/h | 160-200kg/h | 200-250kg/h |

| Appearance size | 14000*1200*2200mm | 16000*1200*2200mm | 33000*1800*2500mm |

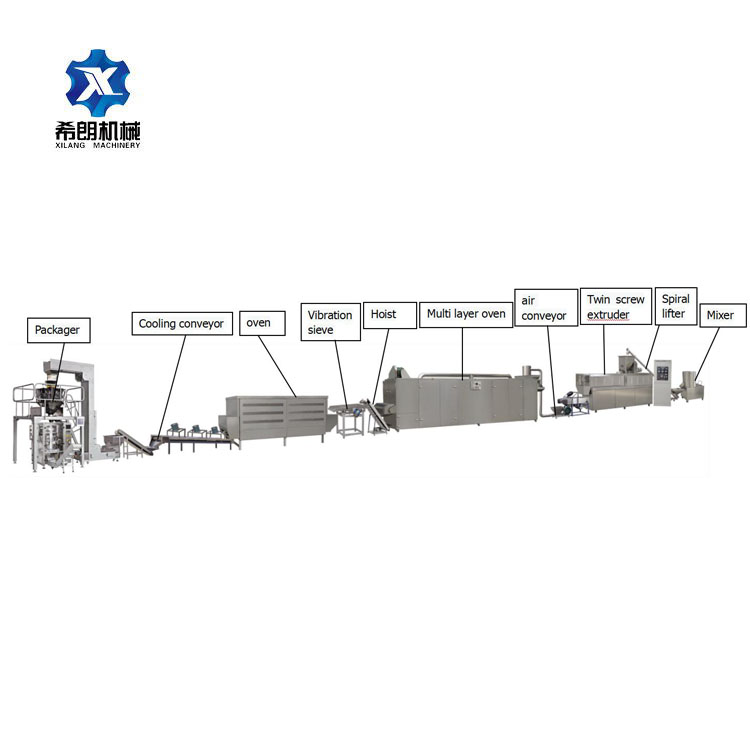

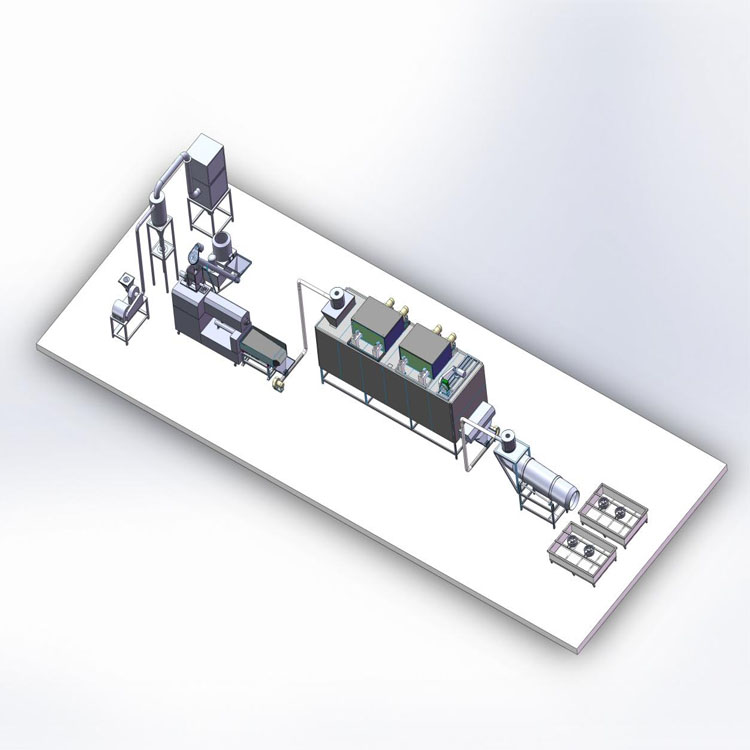

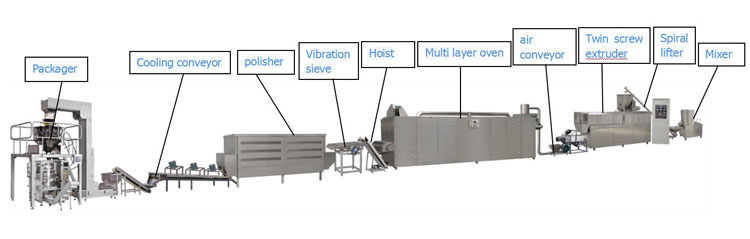

3.Flow Chart of Instant Nutrition Rice Production Line

Whole Processing Line:

Material mixing with water→ material conveying → extruding → drying → secondary puffing → cooling → Storage

Equipments List of Instant Rice Processing Line:

①Mixer→②Screw Feeder→③Twin Screw Extruder→④Vibrating Screen→⑤Air Conveyor→⑥Muti-layer Dryer→

⑦Hoist →⑧Vibrating Screen→⑨High-temperature inflated dryer→⑩Cooling Conveyor→11.Vertical Packing Machine

The composition of Self-heating Instant Rice Production Line:

No | Name | Function |

1 | Mixer | Mix all the raw materials (powder form) with water or other liquid additives |

2 | Screw Feeder | Convey the mixed materials to the extruder without any leaking,dusting and pollution |

3 | Twin screw extruder | Extrude and cook raw material into different size and shapes |

4 | Vibrating screen | The screen shakes continuously by the vibrate motor, which effectively prevent the extruded products from sticking together,and cool them down. |

Vibrating screen | it is maily used for material high humidity steam emitting and cooling,to prevent particles bonding. | |

5 | Air conveyor | Transport the extruded materials into dryer. It has the characters of less energy consumption,high efficiency,no leakage of food transportation,no pollution etc. |

6 | Muti-layer Dryer | Bake and dry products.There are 3/5/7 layes inside,each layer is 5-12 meters long, it can save space and energy. The heating source can be electric, gas, steam and fuel. 304 stainless steel protective plate,food and chain to prevent contact,Net bag transfer frequency control. Drying time:20-40min |

7 | Hoist | Transport the dried product to Vibrating screen |

8 | Vibrating screen | The product is dispersed and cooled by continuous vibration |

9 | High-temperature inflated dryer | High temperature secondary puffing for instant self-heating rice,porridge,corn flakes,breakfast cereal etc. |

10 | Cooling Conveyor | Cooling and conveying the finished artificial rice products to the the packing machine. |

11 | Vertical Packing Machine | Pack artificial rice products automaticly and diversely |

Finished Machines:

4.Sample Photos of Instant Self-heating Rice Production Line

This machine line can produce different rice products,such as nutrition rice, fortified rice, golden ric,puffed rice,etc.and the rice molds can be customized according to your target shape and size

5.Extruder Features:

1.The main extruder adopts frequency speed controlling with high automation and stable per-formation.

2.Alloy (38CrMoAL) screw made by nitriding process, high strength and wear-resting. strong self-cleaning ability. There is no need to discharge for cleanning the barrel and screw when roasting or replacing of materials.

3.Visual automatic temperature control system, accurate parameters, easy to operate.

4.Forced lubrication system is adopted to prolong the service life of the equipment.

6.Packing and Shipping

1. Inner packing: Stretch film

2. Outside packing: Standard export wooden cases

3. The package also can be according to customer requirements.

7.Company Profile:

Jinan Xilang Machine Co.,ltd is a professional Manufacturer specializing in researching and producing Extrusion machinery,Industrial microwave drying and sterilizing equipment and related ancillary equipment.The Company is located in Jinan,the spring city of Shandong. With the strong design strength,advanced producing technology and rich manufacturing experience,the company`s products get good comments from domestic and abroad customers.

Our main products include machinery and equipment for pasta system, corn flakes system, breakfast cereal system, baby food system, corn puff snacks system, fried pellets system, fortified nutrition rice system,soy nuggets system, pet food system , fish feed system , various type drying oven system, corn meal milling system etc.

Our machines have been exported to many countries of Asia, America, Africa, Europe etc. So Don't hesitate to contact us. Xilang team from pre -service to after-service will show your choice is worth it.

8.FAQ

Q1: Are you a trade company or a manufacturer?

A:We are a manufacturer,we have own factory and R&D department.SGS has certified our company on site.welcome to visit our factory and check the machines.

Q2: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-35 days if the goods are not in stock, we could discuss before contract.

Q3: Could you supply all the parameters about the machines?

A: Yes, we will supply all the parameters, price, layout drawing, factory design etc.

Q4. Can you provide food or feed formula ?

A: We can provide basic formula for produce the food etc.And help customer to produce new products according to customer’s formula.

Q5: What is your terms of payment ?

A: 30% T/T in advance ,70% balance before shippment after inspection.

Q6: How about the after-service?

A: We will send 1 engineer to the buyer's factory for 7-14 days period installation and training to the operators.