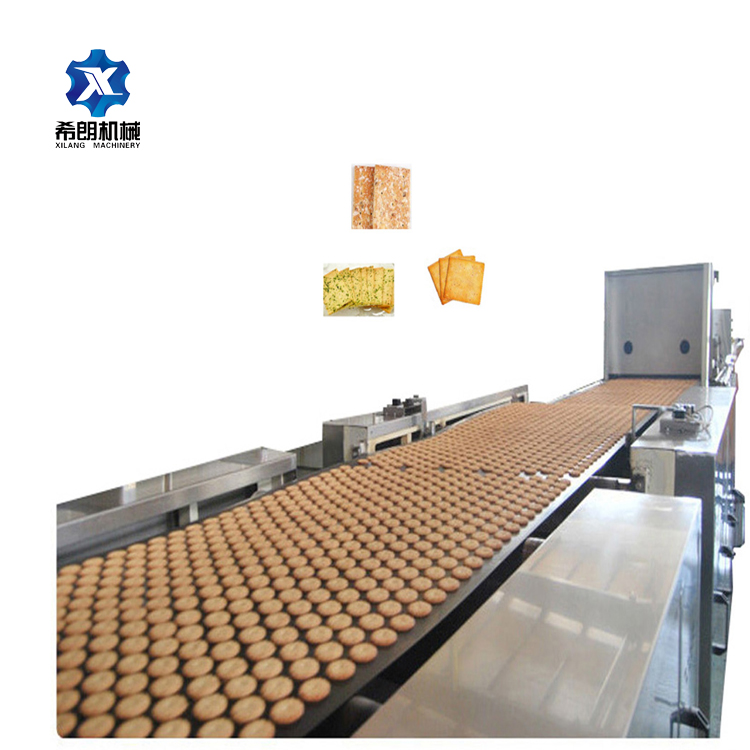

Automatic Complete Biscuit Production Line for food factory

Brand :XILANG

Product origin :Jinan,China

Delivery time :20days

Supply capacity :100 sets per month

1. Technology: The whole line of cookie production line adopts CPU module control, backhanging motor drive, compact structure, high degree of automation, from feeding, three pressure surface, forming, sugar screening, transportation, waste material, recycling. Baking, oil spraying, cooling and other mechanical and electrical integration automatically completed

2. Products: The company provides thousands of molds and dozens of technological formulations. Customers can produce a variety of cookie products by adjusting the molds and formulations. Such as cookies, soda crackers, crackers, cartoon crackers and so on.

3. Service: Xilang automatic biscuit production line, equipment configuration can be customized according to demand. Just determine your own plant size, pre-output products and output, we can provide you with the best solution.

Cookies Biscuit Cracker Production Line

Brief introduction:

biscuit production line by the biscuit forming machine, tunnel type hot air circulation electric oven, injection machine, turning machine, cooling line, biscuits, sorting machine, biscuit sandwich machine, packing machine and other equipment, from feed to three pressure surface forming sift sugar, transport, waste recycling, baking oil, cooling all mechanical and electrical integration automatically, arbitrary adjustable thickness of biscuits, Mechanical speed can be fast or slow stepless adjustment, and has a series of advanced equipment such as automatic temperature control. The production line has the function of roll cutting and roll printing, so it can produce both tough biscuits and crisp biscuits. There are more than 1000 kinds of mold patterns.

The technical specification of biscuit production line

Model No. | Production capacity | Width of conveying belt | Power rate for tunnel oven | Voltage |

XL-400 | 100-200kg/h | 400mm | 6.75kw/m | 380V,50Hz |

XL-600 | 300-500kg/h | 600mm | 8kw/m | 380V,50Hz |

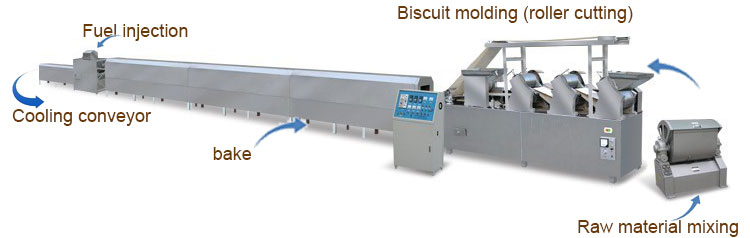

Biscuit prduction line process flow

1. Flour mixer — 2. Roll cut biscuit forming machine — 3.Roll print biscuit forming machine — 4.Tunnel oven — 5.180degree Turning machine — 6.Oil spraying machine — 7.Cooling line — 8.Biscuit stacking machine — 9.Biscuit sandwich machine — 10.Biscuit packing machine

Consist of a biscuit line

1.Horizontal dough mixer

2.Automatic dough tipper and feeding system

3.Three-roll combination sheeter for feeding and sheeting the dough

4.Laminator for overlapping dough to sheeting on gauge rolls, included cream spreading machine.

5.Gauge rolls

6.Rotary cutting machine for hard biscuit forming

7.Scrap collection and return system

8.Rotary moulder for soft biscuit forming

9.Salt/sugar spreading machine

10.Tunnel oven.Three kinds of heating source: Electric, Natural Gas, Liquefied Petroleum Gas.

11.Oil spraying machine

12.Turning machine 180degree or 90degree design as per the plant length

13.Cooling conveyor

14.Biscuit stacking machine

15.Packing table

Our Service |

1)Provide factory layout according to your factory size in advance; |

2)Provide the basic formula; |

3)Inspect the machine before leaving the factory;Oversea installation and commissioning equipment; |

4)Technician will work with your workers together and teach your workers how to install machines, |

how to operate machines, how to maintain machines during daily working; |

5)Our engineers will teach your workers how to clean the extruder, how to change the screw, |

how to change barrel etc, and provide technology support with you forever; |

6)Provide English Version of Installation / Operation / Service / Maintenance Manual. |

Packing and Delivery:

1.Packaging: All machines are packaged according to international standard export package.Inside is covered by plastic film, outside is wooden case.

Customer & Exhibition

Company Profile:

Jinan Xilang Machine Co.,ltd is a professional Manufacturer specializing in researching and producing Extrusion machinery,Industrial microwave drying and sterilizing equipment and related ancillary equipment.The Company is located in Jinan,the spring city of Shandong. With the strong design strength,advanced producing technology and rich manufacturing experience,the company`s products get good comments from domestic and abroad customers.

Our main products include machinery and equipment for pasta system, corn flakes system, breakfast cereal system, baby food system, corn puff snacks system, fried pellets system, fortified nutrition rice system,soy nuggets system, pet food system , fish feed system , various type drying oven system, corn meal milling system etc.

Our machines have been exported to many countries of Asia, America, Africa, Europe etc. So Don't hesitate to contact us. Xilang team from pre -service to after-service will show your choice is worth it.

FAQ

1. What's the pre-sale service of your company for biscuit production line ?

Related machines’s technical parameter will be supplied to customer.

1.1 Layout can be provided in advance basing on customer’s factory size.

1.2 General formulation can be offered according to customer’s material cost,.

1.3 Machine could be customization.

1.4 Professional suggestion for Market, machines, processing , materials, packing.

1.5 Suggesting professional ship agent or helping book ship according to customer situation.

2. What's the after-sale service of your company for biscuit production line?

2.1. Allocation chart will be offered as the buyer’s request .

2.2. Professional Operation manual will be supplied after shipment.

2.3. One year warranty support, life time maintenance with cost price.

2.4. Free easy broken spare parts will be sent together with machines .

2.5. First installation supports.

2.6. Worker training supports.

3. what about spare parts after sale service for biscuit production line?

We can offer the wearing parts all the time together with changing video.

4 Are you manufacturer or trading company?

We are the manufactuer,welcome to visit us.

5 Whether you could make your brand on the products?

Yes, we could print your logo on both products and packages.

6 What is the terms of payment?

30% T/T in advance, the balance before goods leave our company.