Auto updated Large output 1 ton/h twin screw extruder pet dog making machine

Brand :Xilang

Product origin :Jinan China

Delivery time :15days

Supply capacity :20 units per month

1.The dog food pellet extrusion machine manufacturing equipments adopt internationally advanced twin screw extrusion technology.

2.The dog food pellet extrusion machine manufacturing equipments have advantages of small investement,high output ,small floor area etc.

Auto updated Large output 1 ton/h twin screw extruder pet dog making machine

1.Brief introduction of dog food pellet extrusion machine manufacturing equipment

The dog food pellet extrusion machine manufacturing equipment is a fully automatic production line based on extrusion technology. The main twin screw extruding machine can efficiently process various ingredients. The mixed materials can be extruded down by a pair of screw pumps that meshing parallel with each other.changing the mold and formula can produce products with different shapes and tastes, to meet the requirements of various pet food.

2.The technical specification of dog food pellet extrusion machine manufacturing equipment

Model | 65twin screw extruder line(dry type) | 70 twin screw extruder line(dry type) | 85 twin screw extruder line | 75 twin screw extruder line | 95twin screw extruder line |

Main machine power | 22kw | 30kw | 37/45 | 55/75 | 90/110 |

Drying type | gas/electric | gas/electric | gas/electric/steam | gas/electric/steam | gas/electric/steam |

Production capacity | 120-150kg/h | 150-180kg/h | 350-500kg/h | 450-600kg/h | 1000-1200kg/h |

Appearance size | 12000x4000x2200mm | 13500x4000x2200mm | 16500x4000x3200mm | 18500x4000x3200mm | 21000x4000x3200mm |

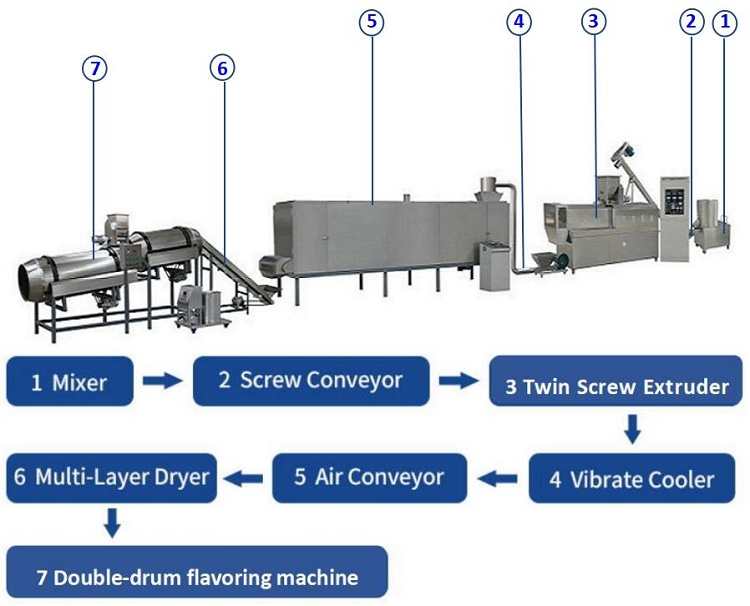

3.The flow chart of dog food pellet extrusion machine manufacturing equipment

grinding→mixing→extruding→drying→flavoring→cooling→packing

4.The composition of dog food pellet extrusion machine manufacturing equipment

mixer→screw conveyor→twin screw extruder→air conveyor→dryer→hoister→flavoring drum and oil sprayer→cooling machine→packing machine

No. | Name | Quantity | Function |

1 | Mixer | 1pc | Mix the raw materials evenly, fast speed, no leakage. |

2 | Screw feeder | 1pc | Convey the mixed materials into twin screw extruder. |

3 | Twin screw extruder | 1pc | Extrude the raw materials and make them to required shape and size of pet food pellets by mould. |

4 | Hoist / Air conveyor | 1pc | Transport the products into dryer. |

5 | Multi-layer oven | 1pc | Roast the products. The Moisture of the dried material is around 9-10%. |

6 | Flavoring machine | 1pc | Season products with flavoring powder and liquid. |

7 | Cooling conveyor | 1pc | Cool and transport finished pet cat and dog for packing. |

5.Main Extruder Features of dog food pellet extrusion machine manufacturing equipment

1)Pure copper motor, low heat, sufficient power and stable performance

2)The control cabinet adopts a visual automatic temperature control system, the temperature of each zone can be adjusted separately, the temperature control is intuitive, and the parameters are accurate

3)Double spiral in the same direction, controlled by a separate control cabinet

4)The screw is made of high wear-resistant materials with hardness above HRC55 and has a long service life

5)International brand power supply devices, strong stability, can run continuously for more than 700 hours

6.Packing and Deliverying

Packaging:

daub coal oil on the surface to protect the machine from moisture, Then cover with plastic film. Finally pack them with wooden case.

Transportation cost:

by ship-please tell me your delivery port; by air-please tell me your airport name; by express-please tell me your detailed address(including zip code, house number, street, city, country).

7.Certificates and Projects

ro

ro

8.Company Profile