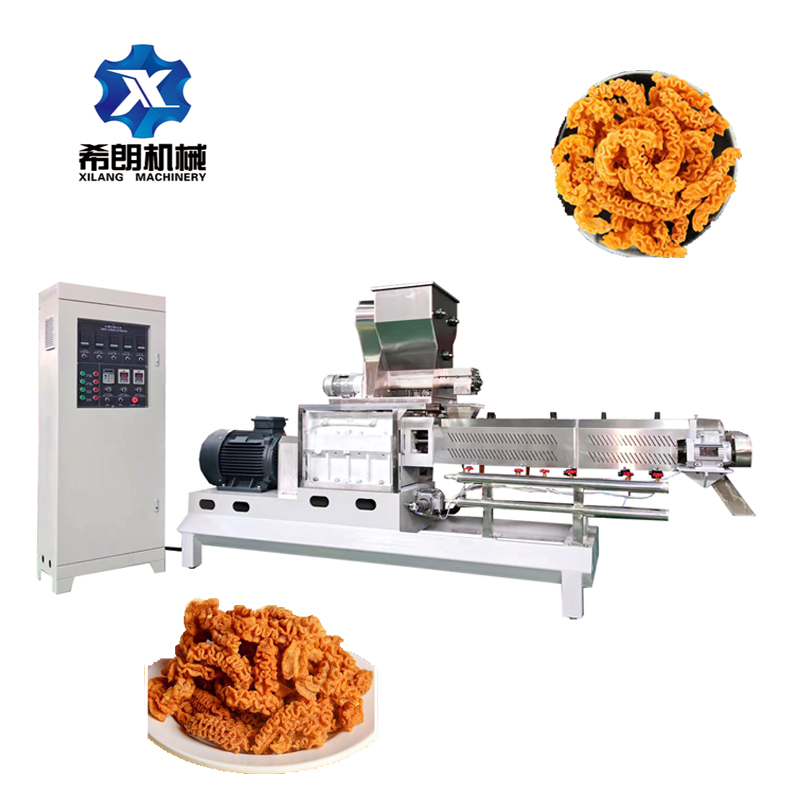

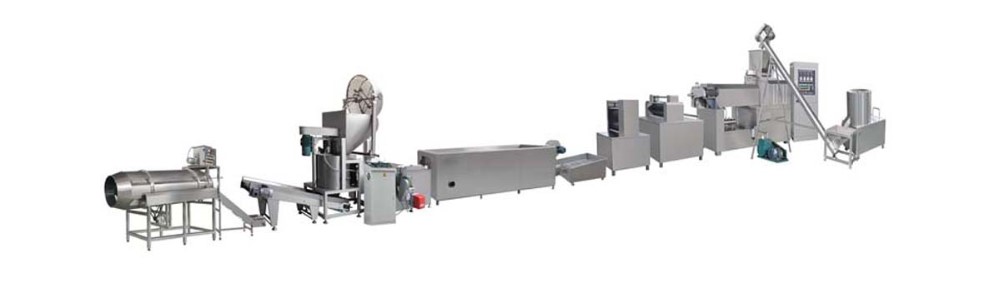

Extruded Fried Snack Food 2D 3D Wheat Flour Bugles Chips Making Machine

Brand :XILANG

Product origin :Jinan,Shandong

Delivery time :20 days

Supply capacity :100 sets per month

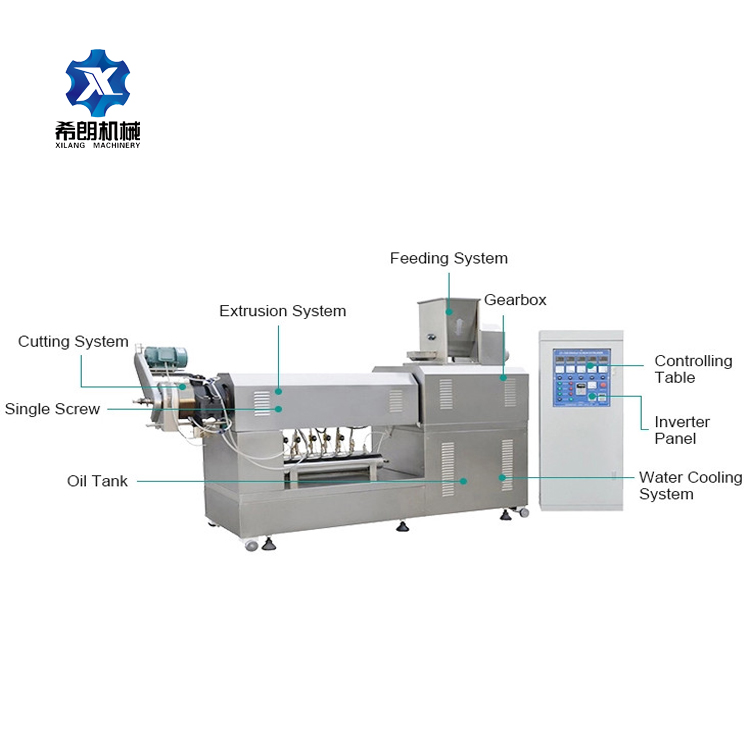

1.Snack food extrusion machine can be used to produce different shapes of pellets by adjusting the moulds from extruder.

2.Converter(used to control the speed of feeding system,cutting system and control system,can protect of the motor)use the brand of Delta,Pioneer,CHNT or Schneider.

3.After-sales Service Provided: Free spare parts, Field installation,Commissioning and training, Field maintenance and repair service, Video technical support, Online support.

4.Guarantee time is 2 year.

China manufacturer Fried 2D 3D Pellet Puff Snack Food Making Extrusion Machine

Fried 2D 3D snacks pellets making equipment introduction

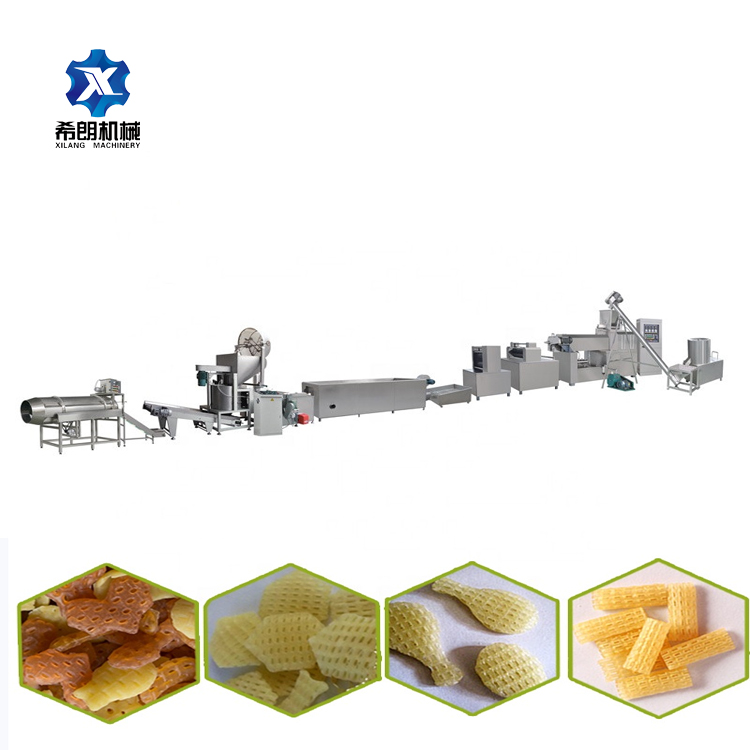

Stainless steel 2d 3d snacks pellets making equipment is characterized by advanced technical, rational configuration, high automation and stable performance.The products taste crispy and delicious after fried. Stainless steel 2d 3d food pellet snack processing line can make different kinds fried snacks, such as rice crusts, chips, bulges, pizza rolls

Raw material of fried 2D 3D snack pellets making equipment:

Potato starch, corn starch, cassava starch, wheat flour, corn flour etc.

The flow chart of fried 2D 3D snack pellets making equipment:

For 2D Snacks Pellet:

Raw material mixer--- Twin screw extruder/single screw extruder --- cooler--- feeding cutter --- rotating dryer --- automatic fryer---automatic flavoring machine

For 3D Snacks Pellet:

Raw material mixer--- Twin screw extruder/single screw extruder --- Patterning --- Shaping -- Separating --- Sieving --- Low temperature drying -- frying -- deoiling -- flavoring

Main Features of fried 2d 3d snack pellets making equipment

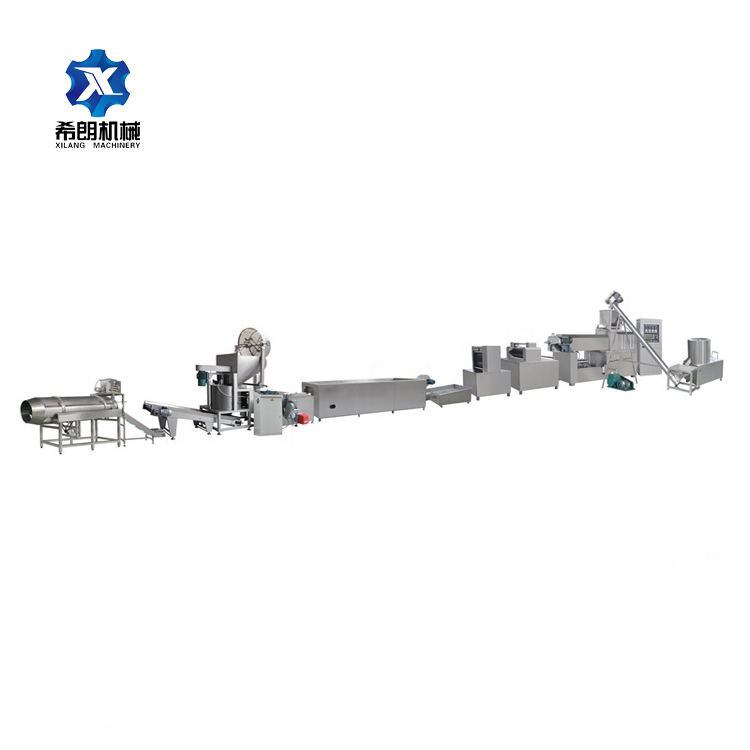

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

Raw material picutre as a reference

Sample picture as a reference

Package & delivery

1.Packaging: All machine are packaged according to international standard export package.Inside is covered by plastic film, outside is wooden case.

2.Shipping: 15-35 working days after receiving deposit.

Our service

a. ) Consultation service before, during, and after sales;

b .) Project planning and design service;

c.) Debugging of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

e.) Training of equipment maintenance and operating personally;

f.) Provide 1 year complete warranty and life-time maintenance service.

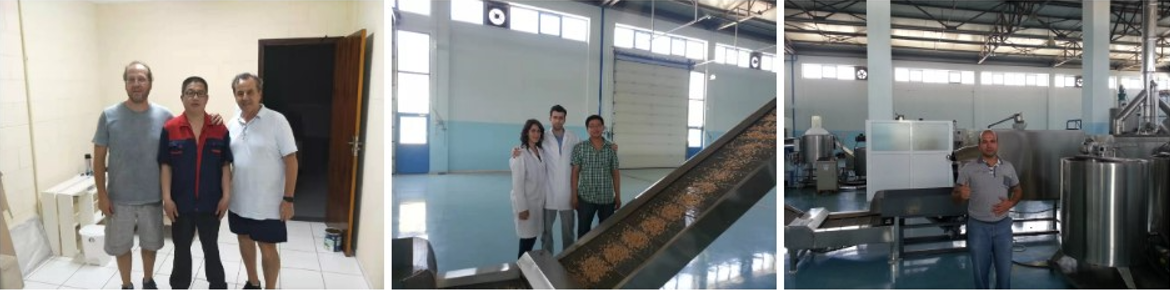

Company profile

Jinan Xilang Machine Co.,ltd is a professional Manufacturer specializing in researching and producing Extrusion machinery,Industrial microwave drying and sterilizing equipment and related ancillary equipment.The Company is located in Jinan,the spring city of Shandong. With the strong design strength,advanced producing technology and rich manufacturing experience,the company`s products get good comments from domestic and abroad customers.

Our main products include machinery and equipment for pasta system, corn flakes system, breakfast cereal system, baby food system, corn puff snacks system, fried pellets system, fortified nutrition rice system,soy nuggets system, pet food system , fish feed system , various type drying oven system, corn meal milling system etc.

Our machines have been exported to many countries of Asia, America, Africa, Europe etc. So Don't hesitate to contact us. Xilang team from pre -service to after-service will show your choice is worth it.

FAQ

1. What's the pre-sale service of your company for fried 2D,3D snack pellet making equipment?

Related machines’s technical parameter will be supplied to customer.

1.1 Layout can be provided in advance basing on customer’s factory size.

1.2 General formulation can be offered according to customer’s material cost,.

1.3 Machine could be customization.

1.4 Professional suggestion for Market, machines, processing , materials, packing.

1.5 Suggesting professional ship agent or helping book ship according to customer situation.

2. What's the after-sale service of your company for fried 2D,3D snack pellet making equipment ?

2.1. Allocation chart will be offered as the buyer’s request .

2.2. Professional Operation manual will be supplied after shipment.

2.3. One year warranty support, life time maintenance with cost price.

2.4. Free easy broken spare parts will be sent together with machines .

2.5. First installation supports.

2.6. Worker training supports.

3. what about spare parts after sale service for fried 2D,3D snack pellet making equipment?

We can offer the wearing parts all the time together with changing video.

We are the manufactuer,welcome to visit us.

Yes, we could print your logo on both products and packages.